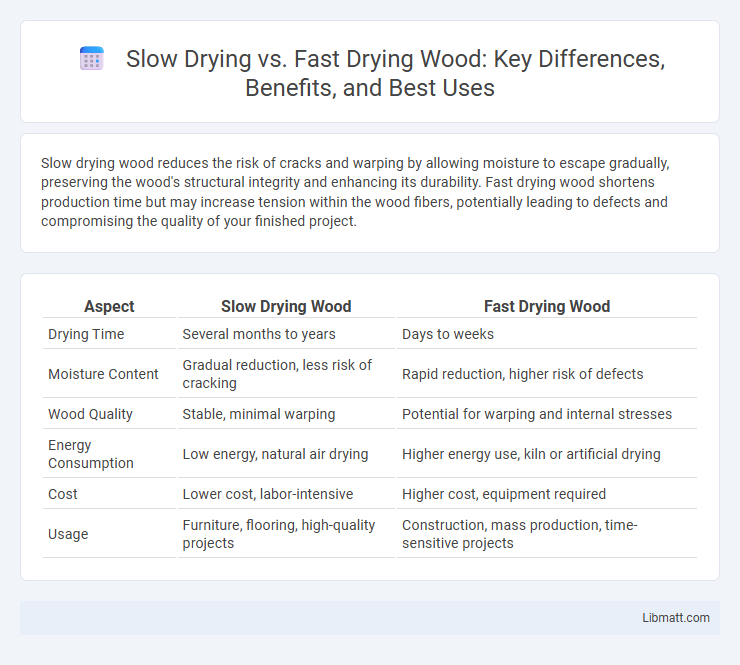

Slow drying wood reduces the risk of cracks and warping by allowing moisture to escape gradually, preserving the wood's structural integrity and enhancing its durability. Fast drying wood shortens production time but may increase tension within the wood fibers, potentially leading to defects and compromising the quality of your finished project.

Table of Comparison

| Aspect | Slow Drying Wood | Fast Drying Wood |

|---|---|---|

| Drying Time | Several months to years | Days to weeks |

| Moisture Content | Gradual reduction, less risk of cracking | Rapid reduction, higher risk of defects |

| Wood Quality | Stable, minimal warping | Potential for warping and internal stresses |

| Energy Consumption | Low energy, natural air drying | Higher energy use, kiln or artificial drying |

| Cost | Lower cost, labor-intensive | Higher cost, equipment required |

| Usage | Furniture, flooring, high-quality projects | Construction, mass production, time-sensitive projects |

Understanding Wood Drying: Slow vs Fast Methods

Slow drying wood reduces internal stresses and minimizes cracking, resulting in higher-quality, more stable lumber ideal for fine woodworking. Fast drying accelerates moisture loss but can cause warping, checking, and reduced strength if not carefully controlled. Understanding the trade-offs between slow and fast drying methods is crucial for optimizing wood performance and durability in construction and furniture making.

Moisture Content: Key Differences in Drying Rates

Moisture content in wood significantly differs between slow drying and fast drying processes, with slow drying allowing for a gradual reduction that minimizes internal stress and reduces the risk of cracks or warping. Fast drying rapidly decreases moisture content but often leads to surface checking and uneven drying due to moisture gradients. Understanding these variations is crucial for optimizing wood quality and stability in applications such as furniture making and construction.

Effects of Drying Speed on Wood Strength

Slow drying wood preserves cellular structure, resulting in higher strength and reduced risk of warping or cracking. Fast drying can cause internal stresses, leading to diminished mechanical properties and increased brittleness. Your choice impacts the wood's durability, with slower drying enhancing long-term performance in construction and woodworking projects.

Impact on Wood Appearance and Grain

Slow drying wood enhances its natural appearance by reducing surface cracks and minimizing warping, resulting in a smoother, more refined grain pattern. Fast drying often causes uneven shrinkage, leading to visible defects such as splits, raised grain, and a rougher texture that diminishes aesthetic quality. Controlled slow drying preserves the wood's natural color variations and intricate grain details, making it ideal for fine woodworking and high-quality finishes.

Risk of Defects: Warping and Cracking

Slow drying wood reduces the risk of warping and cracking by allowing moisture to evaporate evenly, maintaining internal stress balance. Fast drying increases the likelihood of defects as rapid moisture loss causes uneven shrinkage, leading to internal tension. Controlled slow drying methods such as kiln drying optimize wood stability, minimizing structural damage and ensuring quality.

Environmental Considerations in Drying Processes

Slow drying wood reduces the risk of defects such as warping and cracking, leading to higher-quality timber and less waste, which supports sustainable forestry practices. Fast drying methods consume more energy and may emit higher levels of volatile organic compounds (VOCs), raising environmental concerns about carbon footprint and air pollution. Choosing appropriate drying techniques is crucial for balancing resource efficiency and minimizing environmental impacts in wood processing.

Cost Implications: Slow vs Fast Drying

Slow drying wood typically incurs higher labor and storage costs due to prolonged drying times, increasing overall expenses. Fast drying methods reduce drying time significantly, lowering labor and inventory holding costs but may involve higher initial investment in technology and energy consumption. Choosing between slow and fast drying approaches depends on balancing operational costs with desired wood quality and market deadlines.

Applications Best Suited for Each Method

Slow drying wood is ideal for high-quality furniture, musical instruments, and flooring where dimensional stability and reduced internal stress are critical, ensuring minimal warping and cracking. Fast drying wood suits construction framing, pallets, and packaging where speed and cost-efficiency outweigh the risks of minor defects. Manufacturers select drying methods based on final product requirements, balancing drying time with wood durability and structural integrity.

Energy Consumption and Sustainability

Slow drying wood consumes less energy overall due to lower heat inputs and reduced risk of defects, leading to less waste and improved material efficiency. Fast drying methods require higher energy consumption through intense heat or forced air systems, increasing operational costs and environmental impact. Sustainable wood drying practices emphasize balancing energy use with wood quality, favoring controlled slow drying to minimize carbon footprint and promote resource conservation.

Choosing the Right Drying Method for Your Project

Choosing the right drying method for your project depends on the wood species, intended use, and timeline. Slow drying preserves wood quality by minimizing defects like warping and cracking, making it ideal for high-quality furniture or structural components. Fast drying accelerates production but may increase internal stresses, suitable for less critical applications or when time constraints are paramount.

Slow drying vs Fast drying wood Infographic

libmatt.com

libmatt.com