SPF (Specific Pathogen Free) and SYP (Standard Yield Protocol) are distinct terms used in different contexts; SPF refers to an environment free of particular pathogens to ensure healthy biological specimens, while SYP relates to standardized methods for assessing productivity or output. Understanding the difference helps you apply the correct standard in research or operational settings.

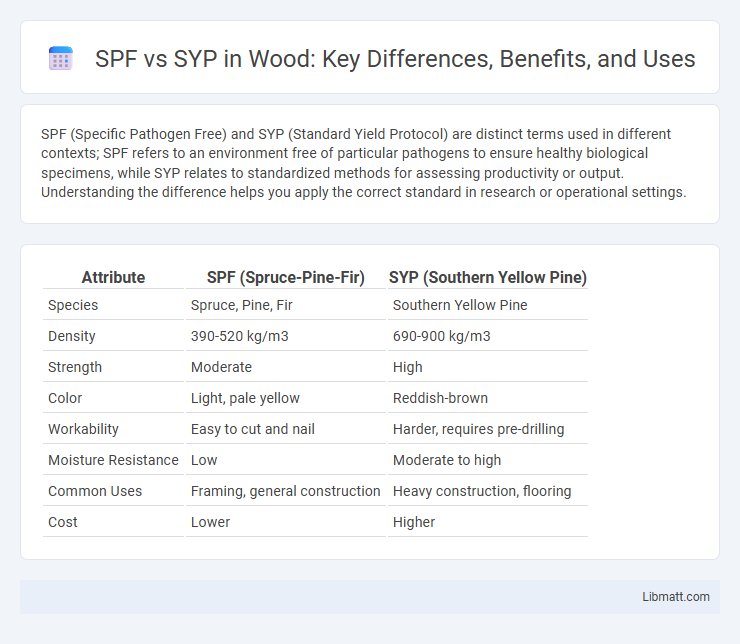

Table of Comparison

| Attribute | SPF (Spruce-Pine-Fir) | SYP (Southern Yellow Pine) |

|---|---|---|

| Species | Spruce, Pine, Fir | Southern Yellow Pine |

| Density | 390-520 kg/m3 | 690-900 kg/m3 |

| Strength | Moderate | High |

| Color | Light, pale yellow | Reddish-brown |

| Workability | Easy to cut and nail | Harder, requires pre-drilling |

| Moisture Resistance | Low | Moderate to high |

| Common Uses | Framing, general construction | Heavy construction, flooring |

| Cost | Lower | Higher |

Introduction to SPF and SYP Lumber

SPF lumber, derived from Spruce, Pine, and Fir species, is renowned for its structural strength and versatility in construction projects such as framing, beams, and trusses. SYP lumber, sourced from Southern Yellow Pine species, offers superior density and hardness, making it ideal for heavy-duty applications like decking, flooring, and outdoor structures. Both SPF and SYP provide distinct benefits, with SPF excelling in lightweight framing and SYP favored for its durability and load-bearing capacity.

Defining SPF: Characteristics and Origins

SPF, or Solid-Phase Foam, is a lightweight, rigid material commonly used in insulation and packaging due to its high thermal resistance and structural integrity. It is created through a chemical process involving the expansion of polymeric substances, resulting in closed-cell foam with excellent moisture resistance. Understanding SPF's unique characteristics and origins helps you choose the right material for energy efficiency and durability in construction or manufacturing projects.

Understanding SYP: Features and Sources

SYP, or Structural Yield Point, measures the stress level at which a material begins to deform plastically, providing critical insights into its mechanical behavior under load. Key features of SYP include its role in identifying the transition from elastic to plastic deformation, which helps engineers design safer and more resilient structures. Common sources for determining SYP values are standardized tensile tests and stress-strain curve analysis conducted in material science laboratories.

Strength and Structural Performance Comparison

SPF (Spruce-Pine-Fir) generally exhibits higher strength properties such as bending strength and modulus of elasticity compared to SYP (Southern Yellow Pine), making it suitable for applications requiring moderate load-bearing capacity. However, SYP is known for superior density and compressive strength, delivering enhanced structural performance in heavy-load and high-stress environments. Engineers often select SYP for beams and posts in construction due to its robust durability and resistance to shear forces, whereas SPF is favored for lightweight framing and flooring systems.

Workability and Ease of Use

SPF (Solid Phenolic) panels offer superior workability with easy cutting and shaping, making them ideal for precise custom applications, while SYP (Southern Yellow Pine) requires more effort and skill due to its denser grain and tendency to splinter. Your choice depends on the balance you need between effortless manipulation and natural wood strength; SPF provides smoother handling for intricate projects. Tools glide more efficiently through SPF, reducing labor time and enhancing overall ease of use compared to raw SYP lumber.

Durability and Resistance to Decay

SPF (Spruce-Pine-Fir) lumber typically offers moderate durability but is more susceptible to decay without proper treatment compared to SYP (Southern Yellow Pine). SYP is known for its superior density and natural resistance to decay and insect damage, making it ideal for outdoor and structural applications. Treating both types with preservatives enhances longevity, but SYP remains the preferred choice for projects demanding high durability and decay resistance.

Cost and Availability Factors

SPF (Spruce-Pine-Fir) typically offers a more cost-effective option compared to SYP (Southern Yellow Pine) due to its wider availability in northern regions, leading to lower transportation expenses. SYP is often priced higher because of its denser grain and greater strength, but it remains readily available in southern U.S. markets where it is harvested. Your choice between SPF and SYP should consider regional supply and price fluctuations influenced by local lumber mills and demand trends.

Common Applications for SPF and SYP

SPF wood, derived from spruce, pine, and fir species, is commonly used for framing, general construction, and sheathing due to its strong structural properties and affordability. SYP, or Southern Yellow Pine, is favored for heavy-duty applications such as flooring, decking, and outdoor structures because of its high density and superior strength. Both SPF and SYP are essential in construction but are selected based on specific requirements like load-bearing capacity and environmental exposure.

Environmental Impact and Sustainability

SPF (Spruce-Pine-Fir) and SYP (Southern Yellow Pine) differ in environmental impact and sustainability, with SPF sourced primarily from sustainably managed northern forests known for faster regrowth and lower carbon footprints. SYP, typically harvested from southern U.S. pine forests, is valued for its dense growth and strength but requires careful management to prevent overharvesting and habitat disruption. You can support sustainable building practices by choosing certified sustainably harvested wood, ensuring minimal ecological impact and promoting forest conservation.

Choosing the Right Lumber: SPF vs SYP

SPF (Spruce-Pine-Fir) and SYP (Southern Yellow Pine) are two common lumber types with distinct characteristics influencing your project's durability and cost. SPF is lighter, easier to work with, and ideal for interior framing, while SYP offers greater strength and hardness, making it suitable for structural applications and outdoor use. Your choice depends on the specific load requirements, environmental exposure, and budget considerations for optimal performance.

SPF vs SYP Infographic

libmatt.com

libmatt.com