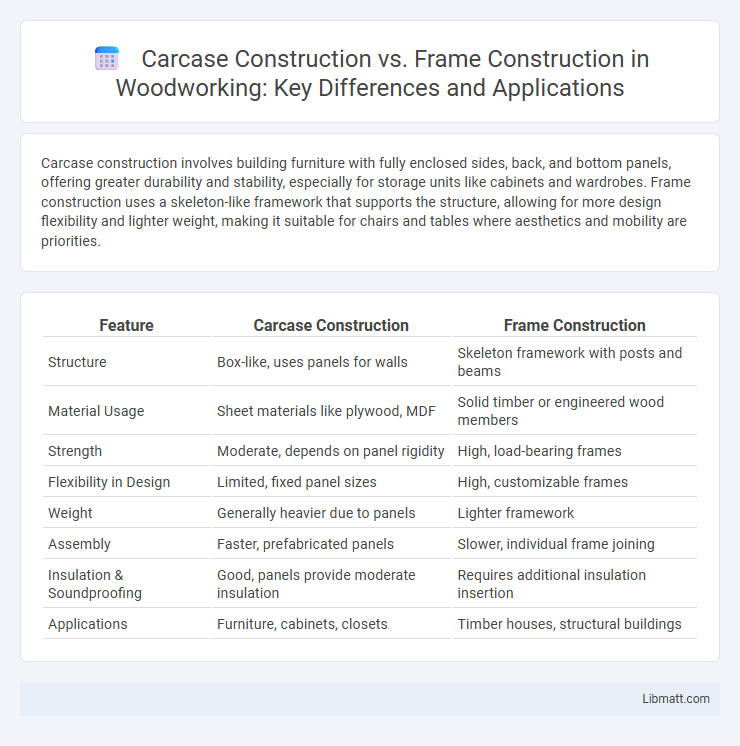

Carcase construction involves building furniture with fully enclosed sides, back, and bottom panels, offering greater durability and stability, especially for storage units like cabinets and wardrobes. Frame construction uses a skeleton-like framework that supports the structure, allowing for more design flexibility and lighter weight, making it suitable for chairs and tables where aesthetics and mobility are priorities.

Table of Comparison

| Feature | Carcase Construction | Frame Construction |

|---|---|---|

| Structure | Box-like, uses panels for walls | Skeleton framework with posts and beams |

| Material Usage | Sheet materials like plywood, MDF | Solid timber or engineered wood members |

| Strength | Moderate, depends on panel rigidity | High, load-bearing frames |

| Flexibility in Design | Limited, fixed panel sizes | High, customizable frames |

| Weight | Generally heavier due to panels | Lighter framework |

| Assembly | Faster, prefabricated panels | Slower, individual frame joining |

| Insulation & Soundproofing | Good, panels provide moderate insulation | Requires additional insulation insertion |

| Applications | Furniture, cabinets, closets | Timber houses, structural buildings |

Introduction to Carcase and Frame Construction

Carcase construction involves assembling a box-like structure, typically using panels made from plywood, MDF, or particleboard, to form strong and stable furniture units such as cabinets and wardrobes. Frame construction relies on a skeleton of solid wood or metal frames, which support the furniture's shape and allow for panel infills, often seen in door frames and traditional furniture pieces. This fundamental difference impacts durability, design flexibility, and manufacturing methods across various types of furniture production.

Defining Carcase Construction

Carcase construction refers to a woodworking technique where the main structure consists of flat panels joined to form a box-like frame, providing rigidity and durability in furniture such as cabinets and wardrobes. This method relies on precise joints and is often preferred for its stability and ease of assembly compared to traditional frame construction, which uses individual stiles and rails to form the skeleton. Understanding carcase construction helps you choose furniture that offers a solid, long-lasting build suited for heavy use.

Defining Frame Construction

Frame construction is a building method that uses a skeleton framework of vertical and horizontal elements, such as studs, beams, and joists, to support the structure. Unlike carcase construction, which relies on solid walls or panels for stability, frame construction distributes loads through the interconnected frame, allowing for greater design flexibility and lighter materials. This technique is commonly employed in residential and commercial buildings due to its efficiency, ease of assembly, and adaptability to different architectural styles.

Key Structural Differences

Carcase construction features a box-like structure where panels form the skeleton of the furniture, providing both shape and strength, while frame construction relies on a framework of solid wood or metal pieces connected by joints to support the piece. In carcase construction, the integrity depends on the quality and thickness of the materials used in the panels, whereas frame construction depends heavily on the precision of joinery techniques such as mortise-and-tenon or dowel joints. Frame construction typically offers greater durability and repairability due to its solid framework, contrasting with the potentially less robust panel assemblies of carcase construction.

Materials Used in Each Method

Carcase construction primarily utilizes plywood, medium-density fiberboard (MDF), and particleboard for the main structure, complemented by solid wood in critical areas to ensure durability. Frame construction relies heavily on solid timber or engineered wood for the skeletal framework, combined with panel materials such as plywood or MDF for surface finishes. The choice of materials in carcase and frame construction directly influences the furniture's strength, weight, and craftsmanship detail.

Advantages of Carcase Construction

Carcase construction offers superior durability and structural integrity due to its solid, enclosed framework, making it ideal for heavy-duty use and long-lasting furniture. It provides better resistance to warping and damage compared to frame construction, ensuring your items maintain their shape and strength over time. The enclosed design also allows for seamless integration of shelves, drawers, and panels, enhancing overall stability and load-bearing capacity.

Advantages of Frame Construction

Frame construction offers superior flexibility in design and ease of modifications compared to carcase construction, making it ideal for custom or evolving projects. The use of standardized components in frame construction facilitates faster assembly and enhanced structural strength, supporting larger spans and varied layouts. Your choice of frame construction can lead to improved durability and simpler maintenance, ensuring long-term performance benefits over carcase methods.

Typical Applications and Furniture Types

Carcase construction is commonly used in cabinetry, wardrobes, and kitchen furniture due to its robust box-like structure that provides stability and storage efficiency. Frame construction is preferred for upholstered furniture and furniture with decorative panels, such as classic chairs and sofas, as it allows for flexibility in design and can accommodate various coverings. Both methods serve distinct furniture types, with carcase favoring function and durability, while frame supports aesthetic customization and comfort.

Durability and Maintenance Considerations

Carcase construction offers enhanced durability due to its solid, box-like structure that resists warping and provides strong support over time. Frame construction, while lighter and easier to repair, may require more frequent maintenance as joints and connections can loosen with use and environmental changes. Understanding your maintenance preferences and the expected wear will help determine which construction method best suits your needs.

Choosing the Right Construction Method

Carcase construction offers durability and structural integrity by using solid panels and fixed joints, ideal for cabinetry where strength is paramount. Frame construction provides flexibility and aesthetic appeal with visible framework and inset panels, making it suitable for furniture requiring a classic or detailed design. Choosing the right construction method depends on your priorities for strength, design style, and ease of repair or modification.

Carcase construction vs Frame construction Infographic

libmatt.com

libmatt.com