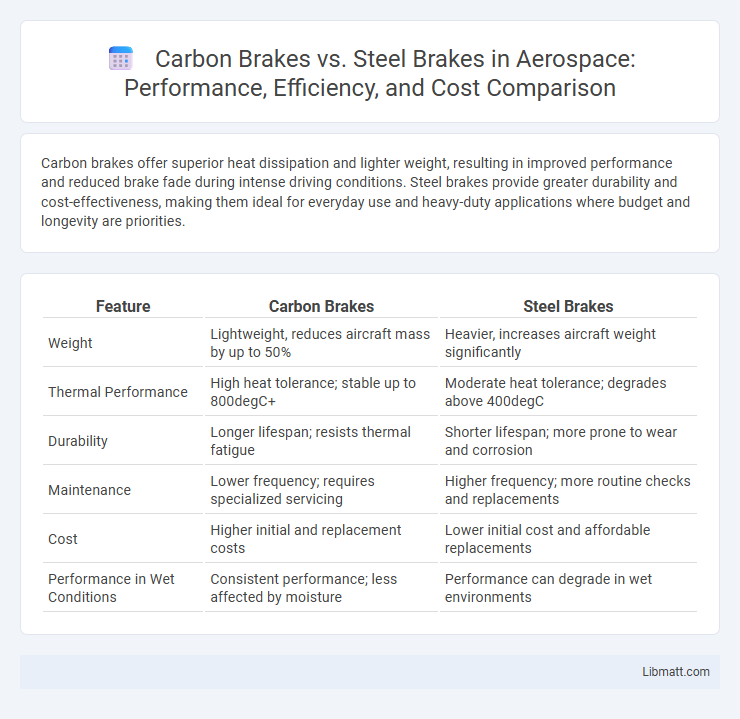

Carbon brakes offer superior heat dissipation and lighter weight, resulting in improved performance and reduced brake fade during intense driving conditions. Steel brakes provide greater durability and cost-effectiveness, making them ideal for everyday use and heavy-duty applications where budget and longevity are priorities.

Table of Comparison

| Feature | Carbon Brakes | Steel Brakes |

|---|---|---|

| Weight | Lightweight, reduces aircraft mass by up to 50% | Heavier, increases aircraft weight significantly |

| Thermal Performance | High heat tolerance; stable up to 800degC+ | Moderate heat tolerance; degrades above 400degC |

| Durability | Longer lifespan; resists thermal fatigue | Shorter lifespan; more prone to wear and corrosion |

| Maintenance | Lower frequency; requires specialized servicing | Higher frequency; more routine checks and replacements |

| Cost | Higher initial and replacement costs | Lower initial cost and affordable replacements |

| Performance in Wet Conditions | Consistent performance; less affected by moisture | Performance can degrade in wet environments |

Introduction to Carbon Brakes vs Steel Brakes

Carbon brakes offer superior heat resistance and lighter weight compared to steel brakes, enhancing overall vehicle performance and efficiency. Steel brakes provide durability and cost-effectiveness, making them a common choice for everyday driving conditions. Your decision between carbon and steel brakes should balance performance needs with budget considerations.

Material Composition and Manufacturing Processes

Carbon brakes are composed primarily of carbon-carbon composite materials, featuring high-carbon fiber reinforcement embedded in a resin matrix, which undergoes a complex curing and carbonization process at extremely high temperatures, enhancing thermal resistance and reducing weight. Steel brakes, on the other hand, consist mainly of cast steel or iron alloys, manufactured through traditional forging and machining processes, offering durability and consistent performance under moderate thermal stress. The advanced manufacturing of carbon brakes results in superior heat dissipation and lighter weight, while steel brakes provide cost-effective production and robust mechanical strength.

Performance Differences: Carbon vs Steel

Carbon brakes offer superior heat dissipation and significantly lower weight compared to steel brakes, enhancing braking performance and reducing overall vehicle mass. Steel brakes excel in durability and cost-effectiveness but tend to suffer from higher thermal degradation and increased stopping distances under extreme conditions. The choice between carbon and steel brakes directly impacts braking efficiency, with carbon brakes providing better fade resistance and consistent performance during high-speed or track use.

Heat Management and Thermal Conductivity

Carbon brakes excel in heat management due to their high thermal conductivity, allowing rapid heat dissipation and reducing brake fade during intense use. Steel brakes have lower thermal conductivity, causing more heat retention and increasing the risk of overheating under heavy braking conditions. Choosing carbon brakes can enhance Your vehicle's braking performance by maintaining optimal temperature levels for consistent stopping power.

Weight Comparison and Impact on Vehicle Efficiency

Carbon brakes weigh significantly less than steel brakes, with carbon composites often reducing brake system weight by up to 50%. This weight reduction enhances vehicle efficiency by lowering unsprung mass, improving acceleration, handling, and fuel economy. Vehicles equipped with carbon brakes typically experience reduced energy consumption due to decreased inertia and improved thermal performance.

Durability and Lifespan in Real-world Usage

Carbon brakes offer superior durability and lifespan compared to steel brakes, especially under high-performance and extreme temperature conditions, due to their resistance to wear and thermal degradation. Steel brakes tend to wear out faster in demanding environments, requiring more frequent replacements and maintenance. Your investment in carbon brakes can result in longer intervals between brake changes, enhancing overall vehicle reliability and reducing long-term costs.

Maintenance Requirements and Costs

Carbon brakes demand specialized maintenance due to their sensitivity to temperature and wear, often requiring expert inspection and occasional resurfacing to preserve optimal performance. Steel brakes involve simpler upkeep, with more frequent pad and rotor replacements but lower overall servicing costs compared to carbon systems. The higher initial cost of carbon brakes is offset by longer lifespan and superior heat resistance, making maintenance expenses variable depending on usage intensity.

Application in Automotive and Aerospace Industries

Carbon brakes offer superior heat resistance, reduced weight, and enhanced durability, making them ideal for high-performance applications in both automotive racing and aerospace sectors. Steel brakes, while heavier and prone to faster wear under extreme conditions, provide cost-effective reliability for everyday automotive use and standard aerospace components. The aerospace industry prioritizes carbon brakes for landing gear and high-stress flight controls, whereas steel brakes are common in commercial vehicles and lower-performance aircraft.

Environmental Impact and Sustainability

Carbon brakes offer a lower environmental impact compared to steel brakes due to their lighter weight, which improves fuel efficiency and reduces greenhouse gas emissions throughout a vehicle's life cycle. The production of carbon brakes involves high energy consumption and use of non-renewable materials, but they last significantly longer than steel brakes, reducing waste and the frequency of replacements. Steel brakes require more frequent manufacturing and disposal, contributing to higher resource depletion and environmental pollution from metal extraction and processing.

Cost Analysis and Return on Investment

Carbon brakes typically cost significantly more upfront, ranging from $5,000 to $12,000 per set compared to steel brakes priced around $500 to $1,500. The higher initial investment in carbon brakes is offset by their longer lifespan, often lasting up to 100,000 miles, whereas steel brakes generally require replacement every 20,000 to 30,000 miles. When analyzing return on investment, carbon brakes offer better value over time due to lower maintenance needs, improved performance, and fuel efficiency gains, which collectively reduce total ownership costs despite the premium price.

Carbon brakes vs Steel brakes Infographic

libmatt.com

libmatt.com