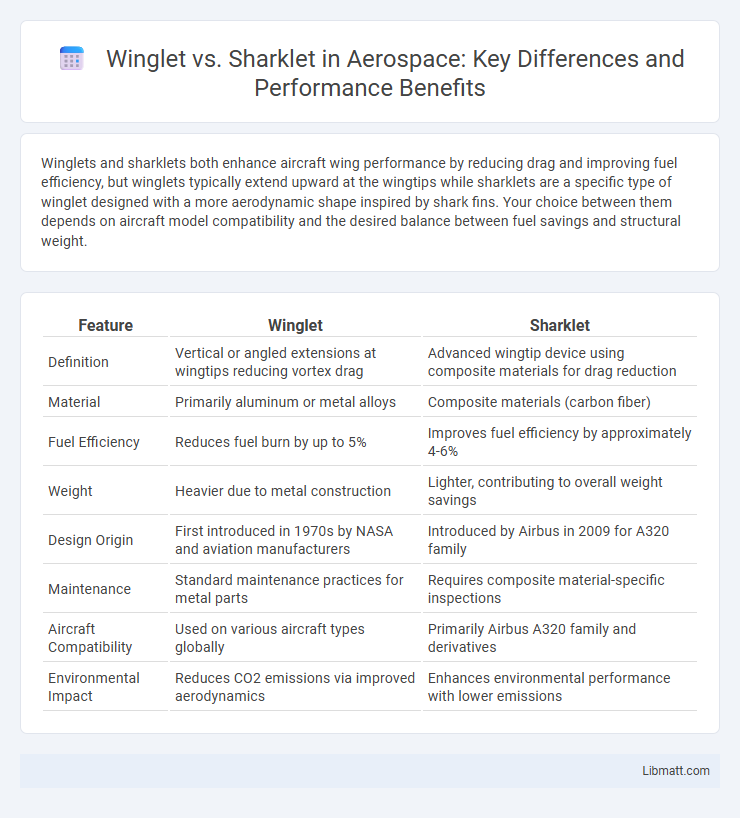

Winglets and sharklets both enhance aircraft wing performance by reducing drag and improving fuel efficiency, but winglets typically extend upward at the wingtips while sharklets are a specific type of winglet designed with a more aerodynamic shape inspired by shark fins. Your choice between them depends on aircraft model compatibility and the desired balance between fuel savings and structural weight.

Table of Comparison

| Feature | Winglet | Sharklet |

|---|---|---|

| Definition | Vertical or angled extensions at wingtips reducing vortex drag | Advanced wingtip device using composite materials for drag reduction |

| Material | Primarily aluminum or metal alloys | Composite materials (carbon fiber) |

| Fuel Efficiency | Reduces fuel burn by up to 5% | Improves fuel efficiency by approximately 4-6% |

| Weight | Heavier due to metal construction | Lighter, contributing to overall weight savings |

| Design Origin | First introduced in 1970s by NASA and aviation manufacturers | Introduced by Airbus in 2009 for A320 family |

| Maintenance | Standard maintenance practices for metal parts | Requires composite material-specific inspections |

| Aircraft Compatibility | Used on various aircraft types globally | Primarily Airbus A320 family and derivatives |

| Environmental Impact | Reduces CO2 emissions via improved aerodynamics | Enhances environmental performance with lower emissions |

Introduction to Winglets and Sharklets

Winglets and Sharklets are aerodynamic devices installed at the wingtips of aircraft to reduce drag and improve fuel efficiency. Winglets, traditionally curved extensions, were first introduced on commercial airliners like the Boeing 737, enhancing lift-to-drag ratios and reducing vortex formation. Sharklets, a modern variant developed by Airbus for aircraft such as the A320 family, feature a blended wingtip design that further optimizes performance and lowers emissions.

Purpose and Function of Wingtip Devices

Winglets and sharklets are aerodynamic wingtip devices designed to reduce vortex drag and improve fuel efficiency by mitigating wingtip vortices created during flight. Winglets typically extend upward or outward from the wingtip, redirecting airflow to decrease induced drag and enhance aircraft performance. Sharklets, a specific type of winglet used primarily on Airbus aircraft, incorporate blended, smoother designs that further optimize aerodynamic efficiency and contribute to lower carbon emissions.

Key Design Differences: Winglet vs Sharklet

Winglets feature a traditional vertical extension at the wingtips designed to reduce vortex drag, while Sharklets incorporate a blended, upward-curved design integrated smoothly with the wing structure. Sharklets typically provide enhanced aerodynamic efficiency by optimizing airflow and reducing fuel burn more effectively than conventional winglets. The composite material composition of Sharklets also contributes to weight savings compared to the metal construction of standard winglets.

Aerodynamic Advantages Explained

Winglets and Sharklets improve aircraft efficiency by reducing wingtip vortices, which lowers drag and enhances lift. Sharklets, designed for modern Airbus aircraft, offer up to 4% fuel savings on longer flights by optimizing airflow with advanced materials and curved shapes. Your choice between them impacts performance, as Sharklets often provide superior aerodynamic benefits compared to traditional winglets.

Fuel Efficiency Comparison

Winglets and Sharklets are advanced wingtip devices designed to improve fuel efficiency by reducing aerodynamic drag and vortex formation. Sharklets, typically used on Airbus aircraft, show a fuel savings of up to 4% compared to traditional wingtips, while Winglets, commonly found on Boeing planes, offer around 3-5% fuel burn reduction depending on the model and flight conditions. Your choice between Winglet or Sharklet technology can significantly impact fuel costs and emissions over the operational life of the aircraft.

Impact on Aircraft Performance

Winglets and Sharklets significantly enhance aircraft performance by reducing induced drag, resulting in improved fuel efficiency and extended range. Sharklets, designed with advanced aerodynamics and materials, offer up to 4% fuel savings compared to traditional winglets by optimizing lift-to-drag ratio and enhancing lift distribution. Both technologies contribute to lower carbon emissions and increased payload capacity, supporting eco-friendly and cost-effective flight operations.

Applications in Commercial Aviation

Winglets and Sharklets improve fuel efficiency and reduce carbon emissions in commercial aviation by minimizing wingtip vortex drag. Sharklets, commonly seen on Airbus A320 family aircraft, provide enhanced lift and contribute to lower operational costs compared to traditional winglets found on many Boeing models. Your airline can benefit from either technology by optimizing fuel consumption, extending aircraft range, and supporting environmental sustainability initiatives.

Maintenance and Cost Considerations

Winglets generally require less maintenance due to their simpler design and proven durability, resulting in lower lifecycle costs. Sharklets, made from advanced composite materials, offer weight savings but may incur higher repair and inspection expenses over time. Airlines must balance the initial investment and maintenance complexity when choosing between winglet and sharklet technologies to optimize operational cost efficiency.

Environmental Benefits of Winglets and Sharklets

Winglets and Sharklets improve fuel efficiency by reducing aerodynamic drag, leading to decreased carbon emissions for aircraft. These wingtip devices enhance lift-to-drag ratios, enabling airlines to consume less fuel on each flight and significantly lower their overall environmental footprint. Their adoption contributes to sustainable aviation by supporting industry goals for reduced greenhouse gas emissions and noise pollution.

Future Trends in Wingtip Technology

Winglet and Sharklet technologies continue to evolve, driven by demands for greater fuel efficiency and reduced carbon emissions in the aviation industry. Advanced composite materials and adaptive wingtip designs, incorporating real-time aerodynamic adjustments, represent key future trends enhancing performance and sustainability. Integration of smart sensors and AI-controlled morphing surfaces will further optimize lift-to-drag ratios and reduce environmental impact in next-generation commercial aircraft.

Winglet vs Sharklet Infographic

libmatt.com

libmatt.com