Failure Mode Effects Analysis identifies potential failure points within a system by examining how individual component failures impact overall performance, helping you prioritize risk mitigation actions. Fault Tree Analysis, on the other hand, uses a top-down approach to visually map the causes of system failures, enabling a structured diagnosis of root causes and their interrelationships.

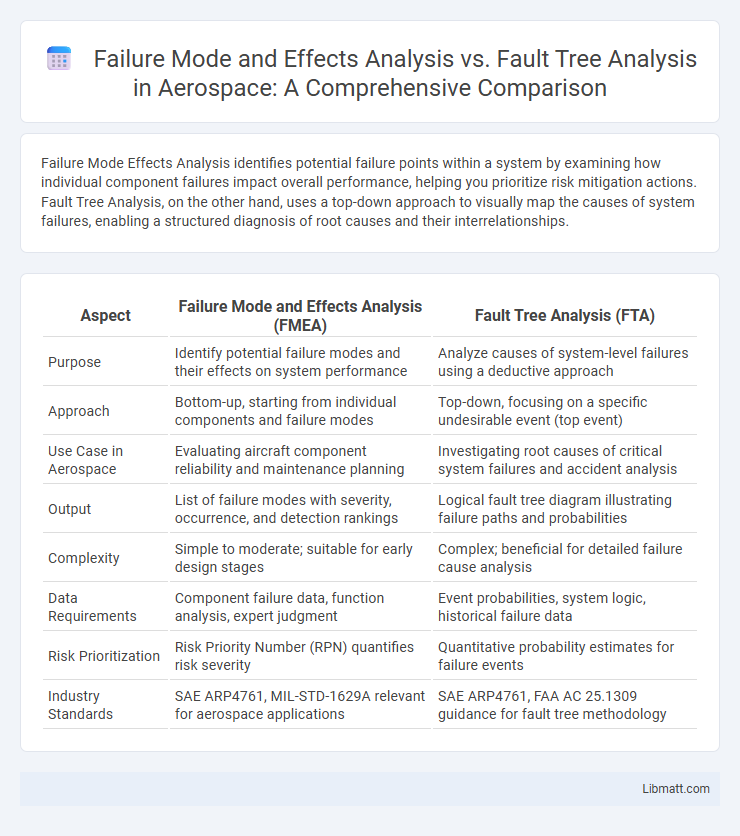

Table of Comparison

| Aspect | Failure Mode and Effects Analysis (FMEA) | Fault Tree Analysis (FTA) |

|---|---|---|

| Purpose | Identify potential failure modes and their effects on system performance | Analyze causes of system-level failures using a deductive approach |

| Approach | Bottom-up, starting from individual components and failure modes | Top-down, focusing on a specific undesirable event (top event) |

| Use Case in Aerospace | Evaluating aircraft component reliability and maintenance planning | Investigating root causes of critical system failures and accident analysis |

| Output | List of failure modes with severity, occurrence, and detection rankings | Logical fault tree diagram illustrating failure paths and probabilities |

| Complexity | Simple to moderate; suitable for early design stages | Complex; beneficial for detailed failure cause analysis |

| Data Requirements | Component failure data, function analysis, expert judgment | Event probabilities, system logic, historical failure data |

| Risk Prioritization | Risk Priority Number (RPN) quantifies risk severity | Quantitative probability estimates for failure events |

| Industry Standards | SAE ARP4761, MIL-STD-1629A relevant for aerospace applications | SAE ARP4761, FAA AC 25.1309 guidance for fault tree methodology |

Introduction to Failure Mode Effects Analysis (FMEA)

Failure Mode Effects Analysis (FMEA) systematically identifies and evaluates potential failure modes within a system, prioritizing them based on their severity, occurrence, and detectability. It enhances risk management by providing a structured approach to analyzing the impact of failures on system performance and safety. FMEA is widely used across industries such as automotive, aerospace, and manufacturing to improve product reliability and prevent defects early in the design process.

Overview of Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method used to identify the root causes of system failures by mapping out fault events in a tree-like structure. It employs Boolean logic to combine various basic events systematically, facilitating the determination of failure probabilities and critical paths. FTA is widely applied in safety-critical industries such as aerospace, nuclear power, and automotive engineering for risk assessment and reliability improvement.

Key Differences Between FMEA and FTA

Failure Mode Effects Analysis (FMEA) systematically identifies potential failure modes and their effects within a system, prioritizing risks based on severity, occurrence, and detection. Fault Tree Analysis (FTA) uses a top-down approach to analyze the root causes of specific system failures through logical gates, focusing on the pathways leading to the undesired event. The key differences lie in FMEA's bottom-up identification of failure modes versus FTA's top-down cause analysis, with FMEA emphasizing risk prioritization and FTA emphasizing fault causality and probability.

When to Use FMEA vs FTA

Use Failure Mode Effects Analysis (FMEA) for early-stage design and process evaluation to identify potential failure modes and their impact on system components. Fault Tree Analysis (FTA) is most effective for root cause investigation and system-level risk assessment, focusing on the logical relationships between failures. Selecting FMEA helps prioritize corrective actions in manufacturing and design, while FTA provides detailed fault paths for complex systems and safety-critical applications.

Step-by-Step Process of Conducting FMEA

Failure Mode Effects Analysis (FMEA) involves identifying potential failure modes, assessing their effects on system performance, and prioritizing risks based on severity, occurrence, and detectability ratings. The step-by-step process begins with assembling a cross-functional team, listing system components, and brainstorming possible failure modes for each component. Each failure mode is then evaluated by assigning risk priority numbers (RPNs), followed by developing and implementing mitigation actions to reduce high-risk failures.

Step-by-Step Process of Conducting FTA

Fault Tree Analysis (FTA) begins by defining the undesired top event and systematically identifying all possible causes through a graphical tree structure using logic gates like AND and OR. Each branch represents basic events or faults, which are successively analyzed to determine how combinations can lead to the top event, enabling quantification of failure probabilities. The final step involves evaluating minimal cut sets to prioritize high-risk contributors and implement effective risk mitigation strategies.

Advantages and Limitations of FMEA

Failure Mode Effects Analysis (FMEA) allows you to systematically identify potential failure modes within a system and prioritize them based on severity, occurrence, and detectability, enhancing preventive measures and design improvements. Its advantages include simplicity, ease of use across multidisciplinary teams, and the ability to improve product reliability early in the development process. Limitations of FMEA involve its reliance on team expertise, potential oversight of complex failure interactions, and the qualitative nature that may require supplementation with quantitative tools like Fault Tree Analysis (FTA) for comprehensive risk assessment.

Advantages and Limitations of FTA

Fault Tree Analysis (FTA) offers a visual and systematic approach to identifying the root causes of system failures by mapping logical relationships between events, making it highly effective for complex systems with interdependent components. Its advantages include clear fault-path visualization, quantitative probability analysis, and suitability for both hardware and software failure diagnostics, enhancing your ability to anticipate and mitigate risks. However, FTA can become unwieldy in extremely complex systems due to its detailed event trees, may require significant expertise to interpret accurately, and often complements rather than replaces other methods like Failure Mode Effects Analysis (FMEA) for comprehensive reliability assessments.

Integrating FMEA and FTA for Comprehensive Risk Assessment

Integrating Failure Mode Effects Analysis (FMEA) and Fault Tree Analysis (FTA) enhances your comprehensive risk assessment by combining FMEA's bottom-up approach with FTA's top-down analysis to identify potential failures and their root causes effectively. This integration allows detailed identification of failure modes with quantifiable fault paths, improving detection, mitigation strategies, and overall system reliability. Utilizing both tools provides a robust framework for risk prioritization and decision-making in complex engineering projects.

Industry Applications: FMEA vs FTA

Failure Mode and Effects Analysis (FMEA) is widely applied in manufacturing and automotive industries to identify potential failure modes at the component or process level, enabling proactive risk mitigation. Fault Tree Analysis (FTA) is extensively used in aerospace, nuclear power, and safety-critical systems to analyze top-level hazards and their causes through logical relationships, supporting system reliability and safety assessments. Both methods complement each other by addressing risk from different analytical perspectives, with FMEA focusing on failure prevention and FTA emphasizing failure cause analysis.

Failure Mode Effects Analysis vs Fault Tree Analysis Infographic

libmatt.com

libmatt.com