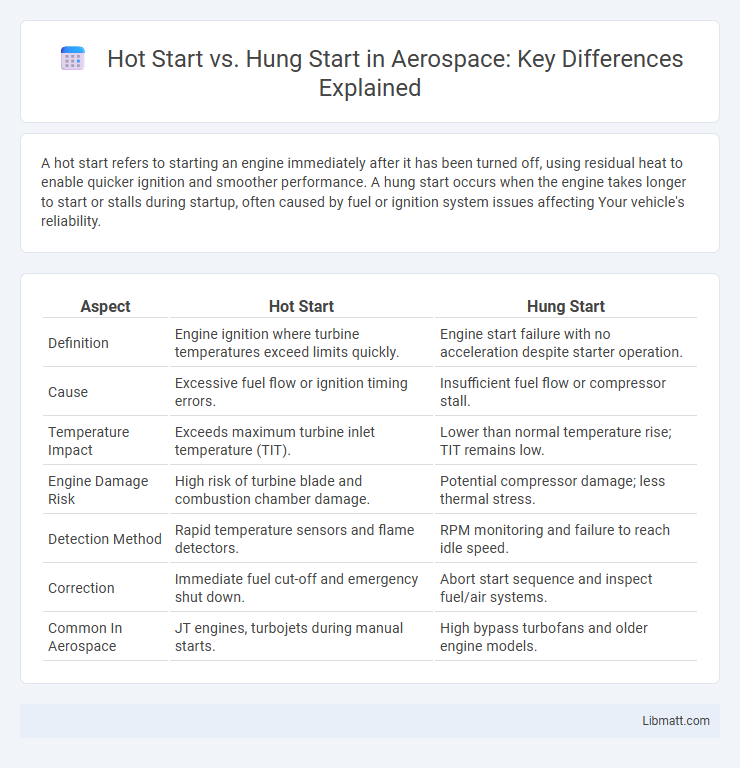

A hot start refers to starting an engine immediately after it has been turned off, using residual heat to enable quicker ignition and smoother performance. A hung start occurs when the engine takes longer to start or stalls during startup, often caused by fuel or ignition system issues affecting Your vehicle's reliability.

Table of Comparison

| Aspect | Hot Start | Hung Start |

|---|---|---|

| Definition | Engine ignition where turbine temperatures exceed limits quickly. | Engine start failure with no acceleration despite starter operation. |

| Cause | Excessive fuel flow or ignition timing errors. | Insufficient fuel flow or compressor stall. |

| Temperature Impact | Exceeds maximum turbine inlet temperature (TIT). | Lower than normal temperature rise; TIT remains low. |

| Engine Damage Risk | High risk of turbine blade and combustion chamber damage. | Potential compressor damage; less thermal stress. |

| Detection Method | Rapid temperature sensors and flame detectors. | RPM monitoring and failure to reach idle speed. |

| Correction | Immediate fuel cut-off and emergency shut down. | Abort start sequence and inspect fuel/air systems. |

| Common In Aerospace | JT engines, turbojets during manual starts. | High bypass turbofans and older engine models. |

Introduction to Hot Start and Hung Start

Hot start refers to the engine starting process when residual heat from a recent operation remains, facilitating quicker ignition and smoother engine performance. Hung start occurs when the engine fails to reach the necessary RPM for stable rotation after ignition, often caused by insufficient fuel flow or compressor stall. Understanding the distinctions between hot start and hung start is critical for diagnosing and preventing engine startup failures in aviation and mechanical systems.

Defining Hot Start: What Does It Mean?

A hot start refers to the process of starting a gas turbine or jet engine when the engine components, especially the combustion chamber and turbine, are already at elevated temperatures from recent operation. This condition demands precise control of fuel flow and ignition timing to prevent overheating or damage during startup. Understanding hot start parameters is crucial for optimizing engine reliability and ensuring safety during your startup procedures.

Explaining Hung Start: Key Features

Hung start refers to an engine start attempt where the engine fails to achieve the necessary rotational speed to initiate normal operation, typically resulting in incomplete combustion or no ignition. Key features include the engine cranking without firing, low battery voltage, fuel delivery issues, or malfunctioning ignition components. Recognizing a hung start helps you diagnose problems such as clogged injectors or faulty spark plugs that prevent successful engine ignition.

Causes of Hot Start in Aircraft Engines

Causes of hot start in aircraft engines include residual heat in the combustion chamber preventing proper fuel ignition, leading to excessive temperatures and potential engine damage. High ambient temperatures, improper fuel mixture settings, or failing components like fuel control units can also contribute to a hot start. Inadequate airflow during the engine start sequence disrupts combustion stability, causing the engine to overheat swiftly.

Causes of Hung Start in Aircraft Engines

Hung start in aircraft engines primarily occurs due to insufficient acceleration of the engine during start-up, often caused by weak battery power, poor fuel delivery, or malfunctioning starter systems. Inadequate fuel-air mixture and compressor stalls can also disrupt the combustion process, preventing the engine from reaching the idle speed. These faults cause the engine to remain in a low RPM state without completing the start sequence, leading to a hung start condition.

Warning Signs and Symptoms of Each Start Type

Hot start warning signs include unusually high turbine temperatures and rapid engine spool-up without corresponding acceleration, indicating potential fuel control or ignition issues. Hung start symptoms involve the engine failing to reach normal idle RPM, sustained low turbine speeds, and sluggish acceleration, often caused by insufficient combustion or fuel flow problems. Early detection of these signs is critical to prevent damage and ensure safe engine operation.

Differences Between Hot Start and Hung Start

Hot start occurs when the engine restarts smoothly while still warm, allowing immediate ignition without complications. Hung start happens when the engine's ignition process stalls or fails to reach full RPM, causing incomplete combustion and potential system damage. Understanding these differences helps you identify and address engine start issues effectively.

Potential Risks and Consequences

Hot start risks include compressor blade damage and turbine overheating due to residual heat causing uneven thermal expansion and reduced cooling efficiency. Hung start can lead to severe engine stall, flameout, or damaged combustor components as fuel-air mixture fails to ignite or stabilize, resulting in abnormal pressure fluctuations. Both conditions pose significant safety hazards, increased maintenance costs, and potential engine failure if not promptly addressed.

Prevention and Troubleshooting Procedures

Hot start prevention involves ensuring proper fuel flow and stable ignition system performance to avoid premature ignition during engine start. Troubleshooting a hot start requires checking fuel control units, ignition timing, and temperature sensors for faults or irregular signals. Hung start prevention and troubleshooting focus on verifying adequate starter torque, fuel delivery, and sufficient airflow to enable complete engine acceleration and combustion initiation.

Best Practices for Safe Engine Start-Ups

Hot start procedures require careful monitoring of turbine inlet temperature and fuel flow to prevent overheating and compressor stalls, making gradual spool-up essential for engine longevity. Hung start conditions occur when the engine fails to accelerate past idle speed due to insufficient combustion or fuel flow issues, necessitating immediate shutdown and troubleshooting to prevent damage. Adhering to manufacturer-specific start limits and performing regular maintenance on fuel control systems ensure optimal engine start-up safety and reduce the risk of hot or hung starts.

hot start vs hung start Infographic

libmatt.com

libmatt.com