Supersonic intakes are designed to efficiently slow down and compress airflow traveling faster than the speed of sound to subsonic speeds before it enters the engine, optimizing performance at high speeds. Subsonic intakes, on the other hand, are tailored for airflow below Mach 1, focusing on smooth air delivery and minimizing drag for efficient engine operation at lower speeds, ensuring your engine receives stable airflow regardless of velocity.

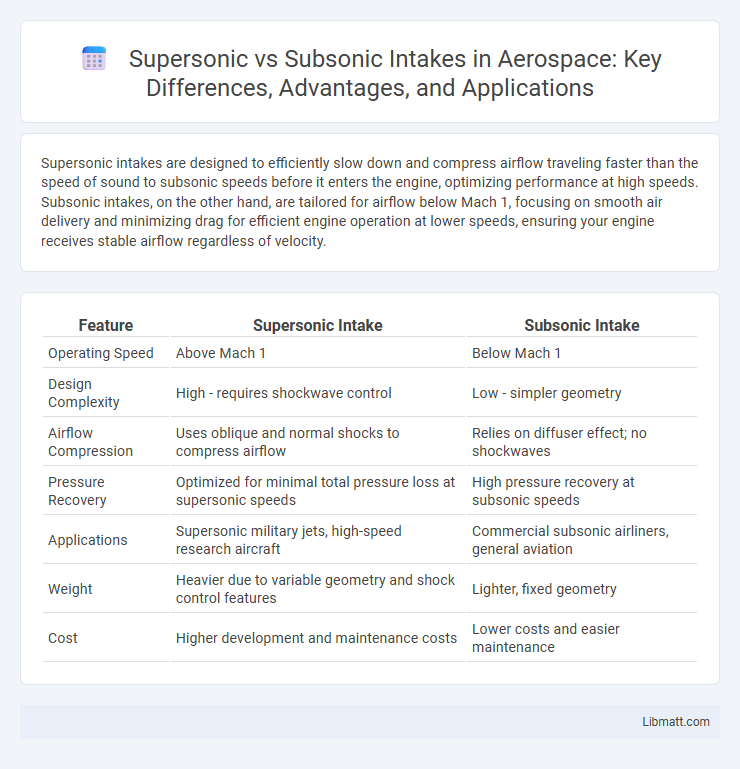

Table of Comparison

| Feature | Supersonic Intake | Subsonic Intake |

|---|---|---|

| Operating Speed | Above Mach 1 | Below Mach 1 |

| Design Complexity | High - requires shockwave control | Low - simpler geometry |

| Airflow Compression | Uses oblique and normal shocks to compress airflow | Relies on diffuser effect; no shockwaves |

| Pressure Recovery | Optimized for minimal total pressure loss at supersonic speeds | High pressure recovery at subsonic speeds |

| Applications | Supersonic military jets, high-speed research aircraft | Commercial subsonic airliners, general aviation |

| Weight | Heavier due to variable geometry and shock control features | Lighter, fixed geometry |

| Cost | Higher development and maintenance costs | Lower costs and easier maintenance |

Introduction to Aircraft Intakes

Aircraft intakes are critical components designed to efficiently channel airflow into the engine under varying flight conditions. Supersonic intakes feature variable geometry and shockwave control to manage airflow deceleration from supersonic to subsonic speeds, optimizing engine performance at high velocities. Subsonic intakes maintain smooth, stable airflow at speeds below Mach 1, focusing on minimizing pressure losses and turbulence for efficient engine operation.

What is a Supersonic Intake?

A supersonic intake is an air intake system designed to efficiently capture and compress airflow traveling at speeds greater than Mach 1 before entering a jet engine or supersonic aircraft propulsion system. It utilizes shock waves to decelerate the supersonic airflow to subsonic speeds, ensuring optimal pressure recovery and engine performance. This intake type is critical in high-speed aircraft like fighter jets and supersonic transports to manage airflow and maintain stable engine operation at supersonic velocities.

What is a Subsonic Intake?

A subsonic intake is an engine air intake system designed to operate efficiently with airflow velocities below the speed of sound, typically used in low-speed aircraft and automotive engines. It ensures smooth, stable airflow into the engine compressor by minimizing shock waves and pressure losses, which are crucial for maintaining optimal engine performance and fuel efficiency. Unlike supersonic intakes, subsonic intakes do not require complex shockwave management, making them simpler, lighter, and more reliable in subsonic flight conditions.

Key Differences Between Supersonic and Subsonic Intakes

Supersonic intakes are designed to efficiently manage airflow at speeds exceeding Mach 1, using shock waves to reduce air velocity before it enters the engine, whereas subsonic intakes are optimized for speeds below Mach 1, ensuring smooth, steady airflow without the need for shock management. Supersonic intakes typically incorporate variable geometry and complex internal structures to handle extreme pressure and temperature changes, while subsonic intakes have simpler, fixed geometries due to less aerodynamic stress. The key difference lies in their operational speed range and airflow control mechanisms, which directly impact engine performance, fuel efficiency, and thermal management in high-speed aircraft.

Aerodynamic Principles Behind Intake Design

Supersonic intakes utilize shock waves to decelerate airflow from supersonic to subsonic speeds before entering the engine, optimizing pressure recovery and engine performance at high speeds. Subsonic intakes are designed to manage airflow efficiently below Mach 1, focusing on minimizing pressure losses and ensuring smooth, stable air delivery to the compressor. Your aircraft's intake design directly influences aerodynamic efficiency, fuel consumption, and overall engine thrust by controlling airflow behavior in varying speed regimes.

Advantages of Supersonic Intakes

Supersonic intakes maximize engine efficiency at high speeds by effectively slowing down and compressing incoming airflow, enabling optimal performance in supersonic and hypersonic flight regimes. These intakes reduce shockwave losses and maintain stable pressure recovery, which enhances thrust and fuel efficiency compared to subsonic intakes designed for lower speed operations. Their ability to manage complex shockwave patterns also improves overall engine stability and operational range in supersonic aircraft.

Advantages of Subsonic Intakes

Subsonic intakes offer improved pressure recovery and reduced drag at low speeds, enhancing overall engine efficiency in commercial and general aviation aircraft. These intakes maintain smooth airflow and prevent shock waves inside the duct, which minimizes flow distortion and mechanical stress on engine components. The simpler design and reliability of subsonic intakes contribute to lower maintenance costs and increased operational lifespan.

Engineering Challenges in Intake Development

Supersonic intake development faces complex engineering challenges such as managing shock waves, controlling airflow compression, and minimizing total pressure loss to ensure efficient engine performance at high speeds. Subsonic intakes prioritize smooth airflow transition and pressure recovery while avoiding flow separation and distortion that can affect engine stability. Your intake design must balance these factors to achieve optimal performance across varying flight regimes.

Applications in Modern Aircraft

Supersonic intakes, designed to efficiently manage airflow at speeds exceeding Mach 1, are critical in military jets and supersonic transport aircraft, where maintaining optimal engine performance and stability at high velocities is essential. Subsonic intakes, optimized for speeds below Mach 1, are commonly used in commercial airliners and general aviation aircraft, providing smooth airflow and fuel efficiency during typical cruise conditions. Your choice of intake type directly impacts engine efficiency, thrust, and overall aircraft performance based on the intended flight speed regime.

Future Trends in Intake Technology

Future trends in intake technology emphasize adaptive supersonic intakes that optimize airflow efficiency at varying speeds, enhancing engine performance in hypersonic and high-speed aircraft. Advances in materials science and computational fluid dynamics enable the development of variable geometry intakes that adjust dynamically to changing flight conditions, reducing drag and thermal loads. Integration of smart sensors and AI-controlled systems further refines intake operation, driving innovation in both supersonic and subsonic propulsion efficiency.

Supersonic Intake vs Subsonic Intake Infographic

libmatt.com

libmatt.com