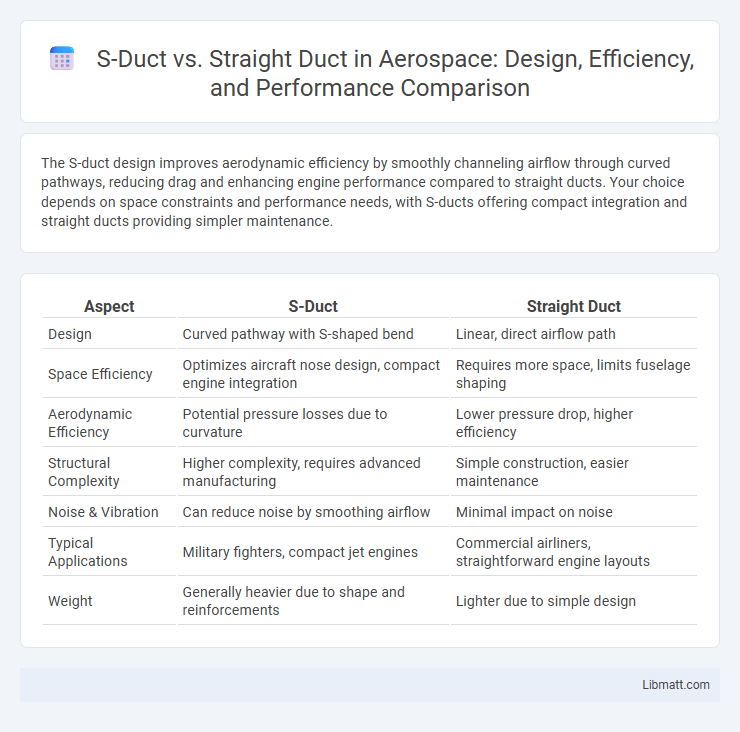

The S-duct design improves aerodynamic efficiency by smoothly channeling airflow through curved pathways, reducing drag and enhancing engine performance compared to straight ducts. Your choice depends on space constraints and performance needs, with S-ducts offering compact integration and straight ducts providing simpler maintenance.

Table of Comparison

| Aspect | S-Duct | Straight Duct |

|---|---|---|

| Design | Curved pathway with S-shaped bend | Linear, direct airflow path |

| Space Efficiency | Optimizes aircraft nose design, compact engine integration | Requires more space, limits fuselage shaping |

| Aerodynamic Efficiency | Potential pressure losses due to curvature | Lower pressure drop, higher efficiency |

| Structural Complexity | Higher complexity, requires advanced manufacturing | Simple construction, easier maintenance |

| Noise & Vibration | Can reduce noise by smoothing airflow | Minimal impact on noise |

| Typical Applications | Military fighters, compact jet engines | Commercial airliners, straightforward engine layouts |

| Weight | Generally heavier due to shape and reinforcements | Lighter due to simple design |

Introduction to Aircraft Engine Duct Designs

Aircraft engine duct designs, such as S-ducts and straight ducts, play crucial roles in optimizing airflow and engine performance. S-ducts are curved and designed to reduce noise and improve aerodynamic efficiency by smoothing airflow to rear-mounted engines, commonly used in trijet configurations. Straight ducts provide a direct path for airflow, offering simplicity and reduced pressure losses, often preferred in twin-engine aircraft with wing-mounted engines to maximize thrust and fuel efficiency.

Overview: S-Duct vs Straight Duct

S-ducts feature a curved design that enhances engine integration by reducing aerodynamic drag and optimizing airflow in aircraft applications, whereas straight ducts provide a simpler, more cost-effective solution with direct airflow paths but may result in less efficient aerodynamic performance. S-ducts are commonly used in stealth and high-performance aircraft to minimize radar cross-section and improve engine cooling, while straight ducts are typical in conventional aircraft designs due to easier manufacturing and maintenance. The choice between S-duct and straight duct is influenced by factors such as aerodynamic efficiency, stealth requirements, and maintenance complexity.

Aerodynamic Efficiency: S-Duct and Straight Duct Compared

S-ducts offer improved aerodynamic efficiency by smoothing airflow transitions between engine inlets and compressors, reducing pressure losses and flow distortions compared to straight ducts. Despite the added complexity and weight, S-duct designs enhance overall engine performance by minimizing drag and optimizing air delivery, especially in aircraft with rear-mounted engines. Your choice between these duct types depends on balancing aerodynamic benefits with design constraints and maintenance considerations.

Impact on Radar Cross-Section and Stealth

S-duct designs significantly reduce Radar Cross-Section (RCS) by bending engine inlets and shielding the compressor face from direct radar exposure, enhancing stealth capabilities in military aircraft. Straight ducts offer less RCS reduction since they provide a direct line of sight to the engine compressor, increasing radar detectability. Incorporating an S-duct into your aircraft design can markedly improve stealth performance by minimizing radar return signals.

Installation Flexibility and Aircraft Configuration

S-duct designs offer greater installation flexibility by enabling engines to be positioned higher on the aircraft fuselage, accommodating various aircraft configurations and improving ground clearance. Straight ducts require a more straightforward engine alignment, limiting adaptability in compact or unconventional airframe layouts. Choosing an S-duct can optimize Your aircraft's aerodynamic integration and internal space management, especially in designs with rear-mounted engines.

Maintenance and Accessibility Considerations

S-ducts generally present more maintenance challenges compared to straight ducts due to their curved design, which can restrict access and complicate inspections and repairs. Straight ducts provide easier accessibility for routine maintenance tasks, allowing for quicker cleaning and component replacement. Improved accessibility in straight ducts often results in reduced downtime during maintenance operations.

Weight and Structural Implications

S-ducts typically weigh more than straight ducts due to their complex curvature and reinforced structural design needed to manage airflow and maintain integrity. The additional material and structural support increase overall weight and can impact aircraft fuel efficiency and balance. Straight ducts offer simpler construction and lighter weight, promoting easier installation and lower structural stress on the airframe.

Performance in Military vs Civilian Aircraft

S-ducts provide superior aerodynamic efficiency in military aircraft by reducing radar cross-section and optimizing airflow to high-performance engines, enhancing thrust and maneuverability crucial for combat scenarios. In civilian aircraft, straight ducts are preferred due to simpler design and maintenance, offering reliable airflow with minimal pressure loss for fuel-efficient, long-haul flights. Your choice between S-duct and straight duct configurations impacts overall aircraft performance, balancing stealth and agility in military applications against operational cost-effectiveness and durability in commercial aviation.

Historical Applications and Notable Examples

The S-duct design, historically utilized in aircraft like the Lockheed Martin F-35 Lightning II, allows for stealthier engine placement by curving airflow to reduce radar signature, contrasting with the simpler, more traditional straight duct used in early jet fighters such as the F-16 Fighting Falcon. Notable examples of S-duct applications are primarily in fifth-generation stealth fighters requiring low observability, while straight ducts dominated in second and third-generation jets prioritizing straightforward engine integration and maintenance. Understanding these historical applications aids in appreciating how Your aircraft choice impacts performance, radar cross-section, and maintenance complexity.

Future Trends in Engine Duct Design

Future trends in engine duct design emphasize improved aerodynamics and noise reduction, with S-ducts gaining popularity due to their compact shape and ability to optimize airflow in high-bypass turbofan engines. Straight ducts remain relevant for simpler maintenance and lower manufacturing costs but may limit aerodynamic efficiency compared to S-duct configurations. Your choice of duct design will increasingly depend on balancing performance improvements with advancements in materials and manufacturing technologies.

S-duct vs Straight duct Infographic

libmatt.com

libmatt.com