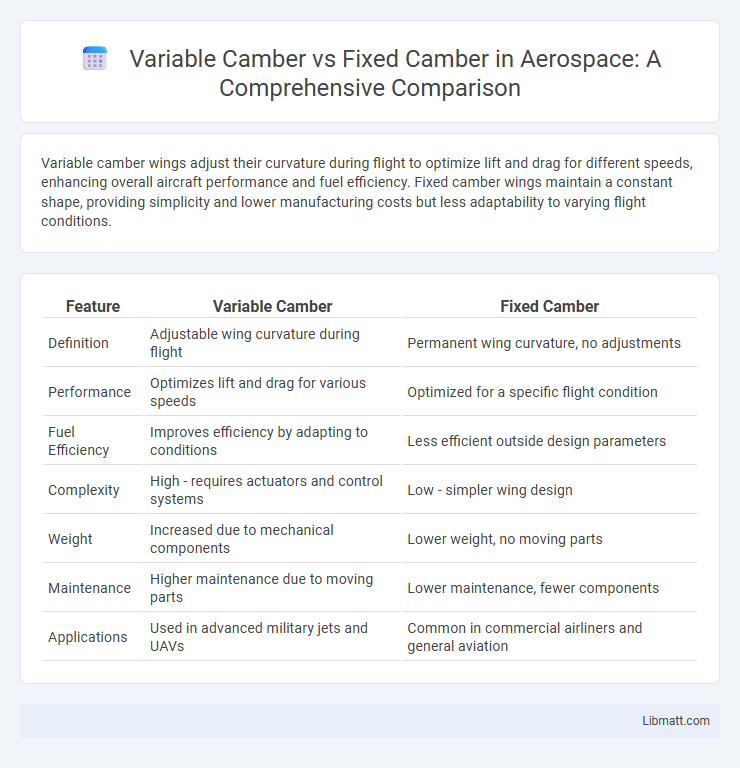

Variable camber wings adjust their curvature during flight to optimize lift and drag for different speeds, enhancing overall aircraft performance and fuel efficiency. Fixed camber wings maintain a constant shape, providing simplicity and lower manufacturing costs but less adaptability to varying flight conditions.

Table of Comparison

| Feature | Variable Camber | Fixed Camber |

|---|---|---|

| Definition | Adjustable wing curvature during flight | Permanent wing curvature, no adjustments |

| Performance | Optimizes lift and drag for various speeds | Optimized for a specific flight condition |

| Fuel Efficiency | Improves efficiency by adapting to conditions | Less efficient outside design parameters |

| Complexity | High - requires actuators and control systems | Low - simpler wing design |

| Weight | Increased due to mechanical components | Lower weight, no moving parts |

| Maintenance | Higher maintenance due to moving parts | Lower maintenance, fewer components |

| Applications | Used in advanced military jets and UAVs | Common in commercial airliners and general aviation |

Introduction to Camber in Aerodynamics

Camber in aerodynamics refers to the curvature of an airfoil's mean line, significantly influencing lift and drag characteristics. Variable camber systems allow dynamic adjustment of this curvature during flight, optimizing performance across different speeds and conditions. Fixed camber airfoils maintain a constant curvature, providing simplicity and structural integrity but limiting adaptability to varying aerodynamic demands.

Defining Variable Camber

Variable camber refers to the ability of an aircraft wing or blade to dynamically change its curvature during flight, optimizing aerodynamic performance for various speeds and maneuvers. Unlike fixed camber, which has a constant curvature designed for a specific flight condition, variable camber systems enhance lift-to-drag ratios by adjusting the airfoil shape in real-time. Your aircraft's efficiency and handling can improve significantly with variable camber technology, especially in diverse operating environments.

Understanding Fixed Camber

Fixed camber airfoils feature a permanent, unchanging curvature along the wing, providing consistent lift characteristics across various flight conditions. This design enhances structural simplicity and reliability but limits adaptability to different speeds or maneuvers compared to variable camber systems. Understanding fixed camber entails recognizing its role in optimizing stability and efficiency during steady flight, especially in general aviation and glider aircraft.

Key Differences Between Variable and Fixed Camber

Variable camber wings offer adjustable curvature that enhances aerodynamic efficiency across different flight conditions, whereas fixed camber wings maintain a constant curvature optimized for a specific flight regime. Variable camber systems enable improved lift-to-drag ratios and better fuel economy by adapting wing shape dynamically. Fixed camber designs are simpler, lighter, and more cost-effective but lack the versatility to optimize performance throughout varying speeds and maneuvers.

Performance Impacts: Variable Camber Advantages

Variable camber wings offer enhanced aerodynamic efficiency by allowing real-time adjustments to the wing shape, optimizing lift and drag for different flight conditions. This adaptability improves fuel efficiency, maneuverability, and overall aircraft performance compared to fixed camber wings, which maintain a constant shape and cannot adjust to varying speeds or payloads. Your aircraft benefits from increased versatility and improved handling characteristics, making variable camber a superior choice for dynamic flight environments.

Efficiency and Design: Fixed Camber Benefits

Fixed camber wings provide consistent aerodynamic efficiency by maintaining a steady airfoil shape optimized for a specific flight condition, reducing drag and enhancing lift. Their simpler design is lighter and structurally more robust, resulting in lower manufacturing and maintenance costs compared to variable camber systems. Your aircraft's performance can benefit from fixed camber's streamlined efficiency, especially in applications where predictable flight dynamics are prioritized.

Applications in Modern Aviation

Variable camber wings enhance aircraft performance by allowing real-time adjustments to the wing shape, optimizing lift and drag across different flight phases, which is crucial for modern military jets and advanced UAVs. Fixed camber wings maintain a constant airfoil shape, providing simplicity and structural efficiency primarily suited for commercial airliners and general aviation where consistent performance and fuel economy are priorities. The adaptability of variable camber technology supports improved maneuverability and fuel efficiency, driving its growing adoption in next-generation aviation platforms.

Challenges and Limitations of Each System

Variable camber systems face challenges such as increased mechanical complexity, higher manufacturing costs, and potential maintenance issues due to moving parts. Fixed camber wings offer simplicity and reliability but lack adaptability, leading to suboptimal performance across diverse flight conditions. You must weigh the trade-off between optimized aerodynamic efficiency and system robustness when choosing between these configurations.

Technology Trends: Future of Camber Control

Variable camber technology is gaining momentum as the automotive and aerospace industries prioritize adaptive aerodynamics for enhanced efficiency and performance. Emerging materials like shape-memory alloys and electroactive polymers enable real-time camber adjustments, reducing drag and improving fuel economy. Fixed camber designs, while simpler and cost-effective, increasingly face limitations in dynamic environments, driving innovation towards intelligent camber control systems integrated with AI for predictive adjustments.

Choosing Between Variable and Fixed Camber

Choosing between variable camber and fixed camber depends on the specific performance requirements and application of an aerodynamic surface. Variable camber allows for real-time adjustments to optimize lift and drag across varying flight conditions, enhancing fuel efficiency and maneuverability. Fixed camber offers simplicity, lower weight, and reliability, making it suitable for applications where consistent aerodynamic characteristics and reduced maintenance are prioritized.

variable camber vs fixed camber Infographic

libmatt.com

libmatt.com