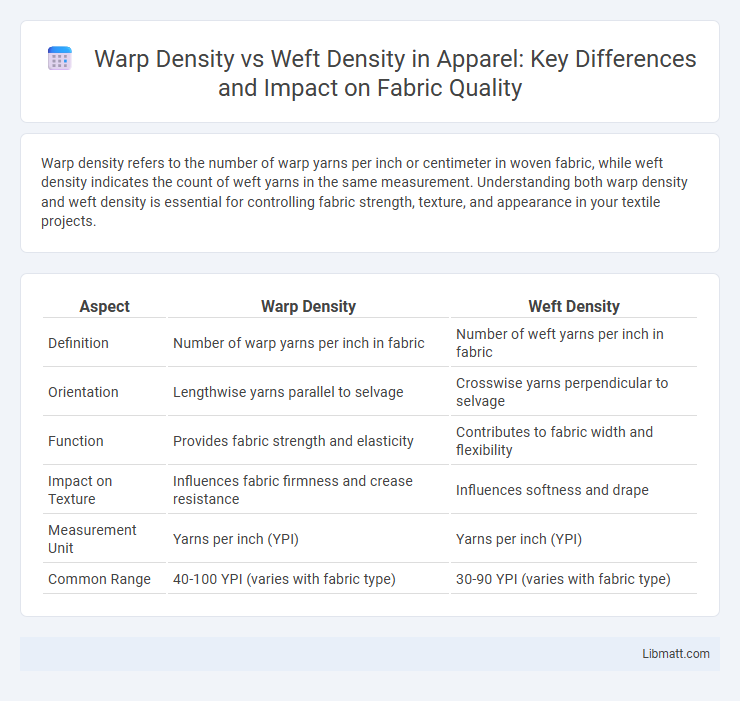

Warp density refers to the number of warp yarns per inch or centimeter in woven fabric, while weft density indicates the count of weft yarns in the same measurement. Understanding both warp density and weft density is essential for controlling fabric strength, texture, and appearance in your textile projects.

Table of Comparison

| Aspect | Warp Density | Weft Density |

|---|---|---|

| Definition | Number of warp yarns per inch in fabric | Number of weft yarns per inch in fabric |

| Orientation | Lengthwise yarns parallel to selvage | Crosswise yarns perpendicular to selvage |

| Function | Provides fabric strength and elasticity | Contributes to fabric width and flexibility |

| Impact on Texture | Influences fabric firmness and crease resistance | Influences softness and drape |

| Measurement Unit | Yarns per inch (YPI) | Yarns per inch (YPI) |

| Common Range | 40-100 YPI (varies with fabric type) | 30-90 YPI (varies with fabric type) |

Introduction to Warp and Weft Density

Warp density refers to the number of warp yarns woven per inch or centimeter in a fabric, while weft density measures the count of weft yarns per inch or centimeter. These densities influence fabric strength, texture, and appearance, with higher warp density enhancing vertical durability and higher weft density contributing to horizontal resilience. Understanding the balance between warp and weft density is essential for optimizing fabric quality and performance in textile manufacturing.

Defining Warp Density

Warp density refers to the number of warp yarns per inch or centimeter in a fabric, directly influencing its strength and durability. Understanding your fabric's warp density is crucial for optimizing weaving quality and ensuring the desired texture and appearance. High warp density typically results in a tighter, more stable fabric suitable for garments requiring durability.

Understanding Weft Density

Weft density refers to the number of weft yarns woven per inch in fabric, directly influencing the material's weight, texture, and durability. Higher weft density increases fabric thickness and enhances resistance to wear, making it crucial for applications requiring strength and comfort. Understanding your fabric's weft density helps optimize production for desired qualities like softness or toughness.

Key Differences Between Warp and Weft Density

Warp density refers to the number of warp threads per inch running lengthwise in a fabric, while weft density measures the number of weft threads per inch running crosswise. The key differences between warp and weft density include their orientation and impact on fabric strength--warp density typically influences tensile strength, whereas weft density affects fabric flexibility. Understanding these distinctions helps you optimize textile design for durability and comfort.

Importance of Warp Density in Fabric Structure

Warp density significantly impacts fabric strength, durability, and texture by determining the number of warp yarns per inch in the fabric. Higher warp density enhances tensile strength and fabric stability, which is crucial for applications requiring robust and long-lasting materials. Understanding your fabric's warp density helps optimize performance and ensures the desired quality in textiles.

Impact of Weft Density on Fabric Properties

Weft density significantly influences fabric attributes such as strength, flexibility, and texture by determining the number of weft yarns per inch in a textile. Higher weft density generally enhances fabric durability and resistance to tearing while reducing air permeability, which improves insulation properties. Variations in weft density directly affect the fabric's weight and drape, making it a critical factor in textile engineering and garment design.

Factors Influencing Warp and Weft Densities

Warp and weft densities are primarily influenced by yarn count, fabric construction, and loom type, with finer yarns enabling higher densities and thus a closer weave. The tension applied during weaving also significantly affects the density, as tighter tension in the warp leads to a more compact structure, while the weft density depends on the pick insertion rate. Your choice of fabric end-use determines the optimal warp and weft densities, balancing strength, flexibility, and texture.

Measuring Warp and Weft Density

Measuring warp density involves counting the number of warp yarns per inch or centimeter along the fabric's length, while weft density refers to the number of weft yarns per inch or centimeter across the fabric's width. Precision in measuring both warp and weft densities is crucial for determining fabric tightness, texture, and quality. Tools such as a pick glass or fabric counter are commonly used to obtain accurate warp and weft density readings in textile manufacturing.

How Warp and Weft Density Affect Fabric Quality

Warp density and weft density directly influence fabric strength, drape, and appearance by determining the number of yarns per inch in the vertical and horizontal directions, respectively. Higher warp density typically enhances tensile strength and vertical stability, while increased weft density improves fabric smoothness and horizontal durability. Optimizing both densities ensures your fabric achieves the desired balance of firmness, flexibility, and overall quality for specific textile applications.

Conclusion: Optimizing Warp and Weft Density for Textile Applications

Optimizing warp and weft density enhances fabric strength, texture, and drape essential for diverse textile applications. Increasing warp density improves tensile strength along the length, while adjusting weft density affects fabric thickness and flexibility. Balancing these parameters ensures your textile product achieves desired durability and comfort tailored to specific end uses.

warp density vs weft density Infographic

libmatt.com

libmatt.com