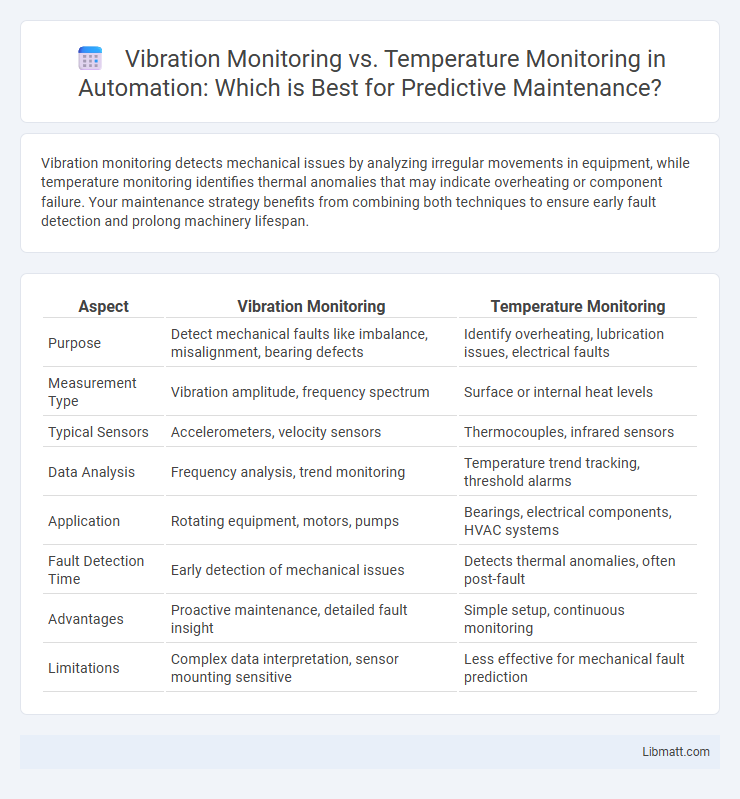

Vibration monitoring detects mechanical issues by analyzing irregular movements in equipment, while temperature monitoring identifies thermal anomalies that may indicate overheating or component failure. Your maintenance strategy benefits from combining both techniques to ensure early fault detection and prolong machinery lifespan.

Table of Comparison

| Aspect | Vibration Monitoring | Temperature Monitoring |

|---|---|---|

| Purpose | Detect mechanical faults like imbalance, misalignment, bearing defects | Identify overheating, lubrication issues, electrical faults |

| Measurement Type | Vibration amplitude, frequency spectrum | Surface or internal heat levels |

| Typical Sensors | Accelerometers, velocity sensors | Thermocouples, infrared sensors |

| Data Analysis | Frequency analysis, trend monitoring | Temperature trend tracking, threshold alarms |

| Application | Rotating equipment, motors, pumps | Bearings, electrical components, HVAC systems |

| Fault Detection Time | Early detection of mechanical issues | Detects thermal anomalies, often post-fault |

| Advantages | Proactive maintenance, detailed fault insight | Simple setup, continuous monitoring |

| Limitations | Complex data interpretation, sensor mounting sensitive | Less effective for mechanical fault prediction |

Introduction to Condition Monitoring

Condition monitoring involves assessing the health of machinery to prevent unexpected failures and optimize maintenance schedules. Vibration monitoring detects abnormalities in mechanical movement by measuring oscillations, while temperature monitoring tracks heat variations that may indicate friction or overheating. Your effective maintenance strategy combines both techniques to ensure comprehensive early fault detection and equipment reliability.

What is Vibration Monitoring?

Vibration monitoring is a predictive maintenance technique used to detect mechanical issues by measuring the frequency and intensity of vibrations in rotating machinery like motors, pumps, and bearings. This method helps identify imbalances, misalignments, and wear before they lead to equipment failure, ensuring operational reliability and reducing downtime. You can enhance your maintenance strategy by integrating vibration monitoring with temperature monitoring for comprehensive machine health assessment.

What is Temperature Monitoring?

Temperature monitoring involves continuously measuring the heat levels of machinery components to detect overheating, which can indicate potential failures or inefficiencies. It uses sensors such as thermocouples or infrared cameras to provide real-time data for predictive maintenance. This method helps prevent equipment damage by identifying abnormal temperature rises that could lead to costly downtime or safety hazards.

Key Differences: Vibration vs Temperature Monitoring

Vibration monitoring detects mechanical faults by measuring oscillations and irregular movements in equipment, providing early signs of imbalance, misalignment, or bearing failures. Temperature monitoring tracks heat levels to identify overheating components, indicating lubrication issues or electrical faults. Your maintenance strategy benefits from combining both methods to achieve comprehensive condition monitoring and prevent unexpected machinery breakdowns.

Applications of Vibration Monitoring

Vibration monitoring is crucial in industries like manufacturing, power generation, and aerospace, where detecting mechanical faults in rotating equipment prevents unexpected failures and costly downtime. It is widely used in predictive maintenance to identify imbalance, misalignment, bearing defects, and gear wear before they escalate. Your facility can benefit from continuous vibration analysis to enhance equipment reliability and extend machinery lifespan.

Applications of Temperature Monitoring

Temperature monitoring is crucial in industries such as manufacturing, power generation, and HVAC systems where maintaining optimal thermal conditions prevents equipment overheating and failure. It is extensively applied in electrical transformers, motors, and bearings to detect abnormal heat build-up indicative of potential faults. Continuous temperature measurement enables predictive maintenance, reduces downtime, and enhances operational safety and efficiency.

Benefits of Vibration Monitoring

Vibration monitoring provides early detection of mechanical faults such as imbalance, misalignment, and bearing wear, enabling proactive maintenance and reducing unplanned downtime. It offers more comprehensive insights into equipment health compared to temperature monitoring, which primarily detects overheating after damage has occurred. Enhanced accuracy in identifying specific issues helps extend asset lifespan and optimize maintenance schedules.

Benefits of Temperature Monitoring

Temperature monitoring enhances equipment reliability by detecting overheating early, preventing costly failures and unscheduled downtime. It offers precise and continuous real-time data that supports predictive maintenance strategies, optimizing asset lifespan. Comparing with vibration monitoring, temperature sensors are often simpler to install and maintain, providing crucial thermal insights for electrical components, bearings, and motors.

Choosing the Right Monitoring Technique

Vibration monitoring excels at detecting mechanical faults such as imbalance, misalignment, and bearing failures, providing early warning before catastrophic breakdowns occur. Temperature monitoring is essential for identifying overheating issues in electrical components and lubrication problems, helping maintain optimal operating conditions. Your decision should consider the specific equipment type and failure modes; integrating both techniques often offers comprehensive protection and improved predictive maintenance.

Conclusion: Integrating Vibration and Temperature Monitoring

Integrating vibration and temperature monitoring enhances predictive maintenance by providing a comprehensive view of equipment health, detecting mechanical faults and thermal anomalies simultaneously. Combining data from both sensors improves early fault detection accuracy, reduces downtime, and extends machinery lifespan. This holistic approach optimizes reliability and operational efficiency in industrial environments.

Vibration Monitoring vs Temperature Monitoring Infographic

libmatt.com

libmatt.com