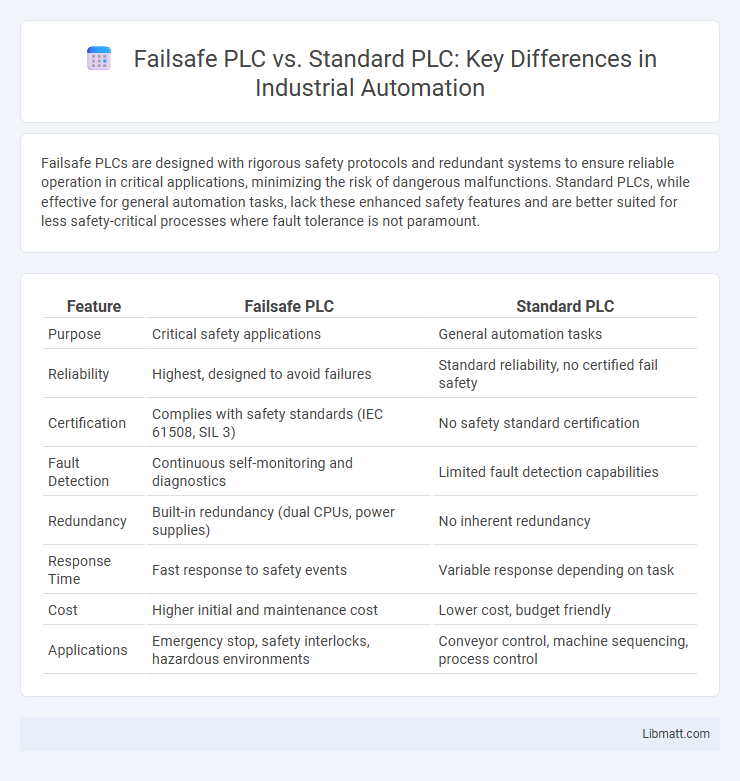

Failsafe PLCs are designed with rigorous safety protocols and redundant systems to ensure reliable operation in critical applications, minimizing the risk of dangerous malfunctions. Standard PLCs, while effective for general automation tasks, lack these enhanced safety features and are better suited for less safety-critical processes where fault tolerance is not paramount.

Table of Comparison

| Feature | Failsafe PLC | Standard PLC |

|---|---|---|

| Purpose | Critical safety applications | General automation tasks |

| Reliability | Highest, designed to avoid failures | Standard reliability, no certified fail safety |

| Certification | Complies with safety standards (IEC 61508, SIL 3) | No safety standard certification |

| Fault Detection | Continuous self-monitoring and diagnostics | Limited fault detection capabilities |

| Redundancy | Built-in redundancy (dual CPUs, power supplies) | No inherent redundancy |

| Response Time | Fast response to safety events | Variable response depending on task |

| Cost | Higher initial and maintenance cost | Lower cost, budget friendly |

| Applications | Emergency stop, safety interlocks, hazardous environments | Conveyor control, machine sequencing, process control |

Introduction to PLC Systems

Failsafe PLC systems prioritize safety by incorporating redundant processors and diagnostics to ensure reliable operation in emergency conditions, essential for critical industries like automotive and aerospace. Standard PLCs primarily focus on general automation tasks without advanced safety features, making them suitable for less hazardous environments such as manufacturing and packaging. Both types use programmable logic to control machinery, but failsafe PLCs meet stringent safety standards like SIL or IEC 61508 for risk reduction.

What is a Standard PLC?

A Standard PLC (Programmable Logic Controller) is an industrial digital computer designed for automation of electromechanical processes, such as machinery control in manufacturing plants. It operates by executing programmed instructions to monitor inputs, make decisions, and control outputs, ensuring efficient process management. Your choice of a Standard PLC depends on the complexity of the application and the need for routine control tasks without advanced safety features.

What is a Failsafe PLC?

A Failsafe PLC is a specialized programmable logic controller designed to ensure safe operation by detecting faults and initiating controlled shutdowns to prevent hazardous situations. Unlike standard PLCs, Failsafe PLCs incorporate redundancy and diagnostic features that continuously monitor safety-critical processes, meeting stringent industry safety standards such as SIL (Safety Integrity Level). Your choice of a Failsafe PLC enhances system reliability and protects human lives and equipment in safety-sensitive environments like manufacturing and automation.

Key Differences Between Failsafe and Standard PLCs

Failsafe PLCs are engineered with advanced redundancy and diagnostic features to ensure continuous operation and safe shutdown in hazardous conditions, unlike standard PLCs which primarily focus on automation without inherent safety mechanisms. Key differences include the failsafe PLC's compliance with strict safety standards such as IEC 61508, its ability to perform self-monitoring and detect faults instantly, and specialized hardware designed to prevent dangerous failures. Understanding these distinctions enables you to select the appropriate PLC for applications where risk mitigation and reliability are critical.

Safety Functions of Failsafe PLCs

Failsafe PLCs integrate advanced safety functions such as redundancy, fault detection, and automatic shutdown protocols to mitigate risks in hazardous environments, ensuring compliance with safety standards like SIL (Safety Integrity Level) and IEC 61508. These controllers continuously monitor inputs and system status, enabling immediate responses to faults or abnormal conditions, which standard PLCs typically lack. The enhanced reliability and diagnostics in failsafe PLCs make them essential for critical applications in industries like oil and gas, automotive manufacturing, and chemical processing.

Applications of Standard PLCs

Standard PLCs are widely used in manufacturing automation, assembly lines, and process control systems where basic monitoring and control tasks do not require advanced safety functions. They efficiently handle machine operation sequences, data acquisition, and communication with other industrial devices, making them ideal for cost-effective automation solutions. Your facility benefits from Standard PLCs in non-critical processes where high reliability and safety certification are not mandatory.

Applications of Failsafe PLCs

Failsafe PLCs are designed for critical applications where safety and reliability are paramount, such as in nuclear power plants, automotive safety systems, and chemical processing industries. These controllers ensure that your machinery operates within strict safety parameters, automatically triggering safe shutdowns during fault conditions to prevent accidents. Unlike standard PLCs, failsafe PLCs integrate redundant hardware and self-monitoring capabilities to maintain safe operation under all circumstances.

Compliance and Industry Standards

Failsafe PLCs are designed to meet stringent compliance requirements such as IEC 61508 and ISO 13849, ensuring they perform critical safety functions and reduce risk in hazardous environments. Standard PLCs typically conform to general industrial automation standards like IEC 61131 but lack the rigorous safety certifications necessary for fail-safe applications. The adoption of certified failsafe PLCs is essential in industries such as automotive, chemical, and oil & gas, where adherence to safety standards is mandatory to protect lives and assets.

Cost and Implementation Considerations

Failsafe PLCs generally incur higher initial costs due to specialized hardware and stringent safety certifications, which are essential for applications demanding reliable fault detection and system redundancy. Implementation of failsafe PLCs often requires more extensive engineering effort, including detailed safety documentation and validation processes, extending project timelines compared to standard PLCs. Standard PLCs offer cost advantages and faster deployment for non-critical applications, but they lack the integrated safety protocols necessary for environments with strict safety regulations.

Choosing the Right PLC for Your Application

Failsafe PLCs provide enhanced reliability and safety features by incorporating fault detection and redundancy essential for critical industrial applications like process control or emergency shutdown systems. Standard PLCs offer cost-effective and versatile solutions suitable for general automation tasks where safety risks are lower and system simplicity is prioritized. Understanding your application's safety requirements, complexity, and regulatory compliance will guide you in selecting the appropriate PLC that ensures both operational efficiency and protection.

Failsafe PLC vs Standard PLC Infographic

libmatt.com

libmatt.com