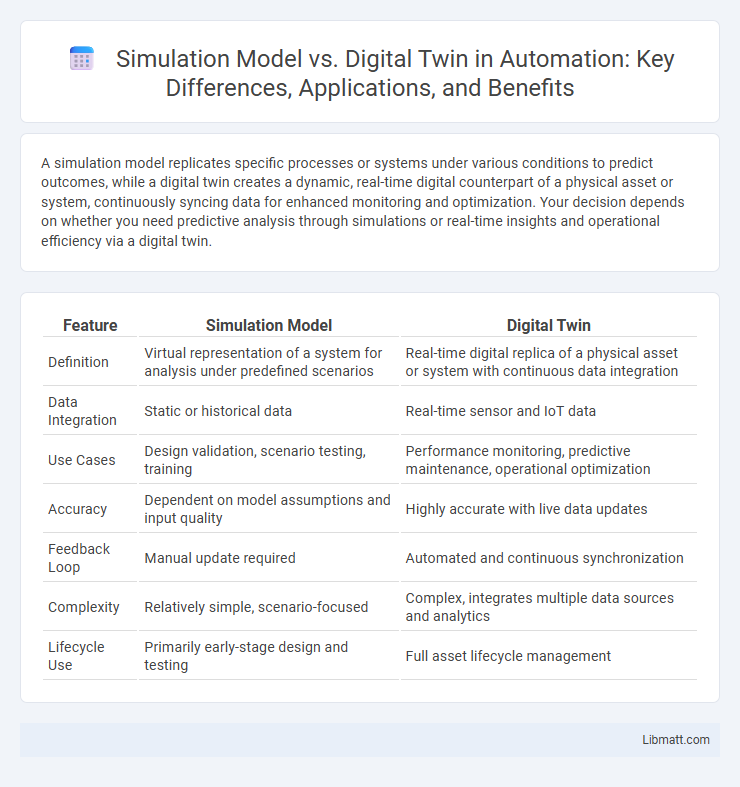

A simulation model replicates specific processes or systems under various conditions to predict outcomes, while a digital twin creates a dynamic, real-time digital counterpart of a physical asset or system, continuously syncing data for enhanced monitoring and optimization. Your decision depends on whether you need predictive analysis through simulations or real-time insights and operational efficiency via a digital twin.

Table of Comparison

| Feature | Simulation Model | Digital Twin |

|---|---|---|

| Definition | Virtual representation of a system for analysis under predefined scenarios | Real-time digital replica of a physical asset or system with continuous data integration |

| Data Integration | Static or historical data | Real-time sensor and IoT data |

| Use Cases | Design validation, scenario testing, training | Performance monitoring, predictive maintenance, operational optimization |

| Accuracy | Dependent on model assumptions and input quality | Highly accurate with live data updates |

| Feedback Loop | Manual update required | Automated and continuous synchronization |

| Complexity | Relatively simple, scenario-focused | Complex, integrates multiple data sources and analytics |

| Lifecycle Use | Primarily early-stage design and testing | Full asset lifecycle management |

Understanding Simulation Models

Simulation models represent mathematical or logical abstractions of real-world systems used to analyze and predict behavior under varying conditions. These models rely on predefined parameters and assumptions to replicate specific processes, offering insights into system performance without direct interaction with physical assets. Unlike digital twins, simulation models do not continuously update in real-time with data from their real-world counterparts, limiting dynamic responsiveness.

Defining Digital Twins

Digital Twins are dynamic, real-time digital replicas of physical assets, processes, or systems that continuously receive data from their real-world counterparts to simulate and predict performance. Unlike static simulation models, Digital Twins integrate IoT sensors, machine learning, and analytics to provide ongoing, real-time insights and enable proactive decision-making. Your ability to optimize operations and foresee potential issues improves significantly with Digital Twins by bridging the physical and digital worlds.

Key Differences Between Simulation Models and Digital Twins

Simulation models use pre-defined scenarios to predict system behavior, while digital twins continuously mirror real-world conditions through real-time data integration. Digital twins offer dynamic feedback from sensors and IoT devices, enabling real-time monitoring and optimization, unlike static simulation models that rely on assumptions. Your decision between these technologies depends on the need for real-time accuracy versus scenario-based analysis.

Core Components of Simulation Models

Simulation models rely on core components such as mathematical formulations, input parameters, and boundary conditions to replicate system behaviors under various scenarios. These models use algorithms and data to predict outcomes, offering insights into performance, efficiency, or risks without real-time interaction. Your understanding of simulation models enhances decision-making by accurately representing system dynamics in a controlled virtual environment.

Essential Features of Digital Twins

Digital twins integrate real-time data, advanced sensors, and IoT connectivity to create dynamic, continuously updated virtual replicas of physical assets. Unlike traditional simulation models that operate on static or pre-defined scenarios, digital twins enable predictive analytics and real-time monitoring, enhancing decision-making and operational efficiency. Key features include bidirectional data flow, seamless integration with live systems, and the ability to simulate complex interactions within the asset's environment.

Real-Time Data Integration in Digital Twins

Digital Twins excel in real-time data integration by continuously syncing with physical assets through sensors, enabling dynamic updates and accurate reflections of current system states. Simulation Models typically rely on static or periodic input data, limiting their ability to adapt instantly to changing conditions. Leveraging real-time data in your Digital Twin enhances predictive analytics and decision-making accuracy compared to conventional simulation approaches.

Use Cases for Simulation Models

Simulation models are extensively used in engineering to predict system behavior under various conditions, such as stress testing in aerospace or automotive design. They enable optimization of manufacturing processes by simulating production workflows and identifying bottlenecks before physical implementation. In healthcare, simulation models assist in drug development and surgical planning by replicating biological processes and patient-specific scenarios.

Applications of Digital Twins Across Industries

Digital twins revolutionize industries by providing real-time, data-driven simulations to optimize operations and foresee potential issues. In manufacturing, they enable predictive maintenance and process optimization, while in healthcare, digital twins simulate patient-specific treatments for improved outcomes. You can leverage digital twins in smart cities for efficient resource management and in automotive for advanced driver assistance system testing, offering unparalleled precision over traditional simulation models.

Benefits and Limitations: Simulation Model vs Digital Twin

Simulation models offer cost-effective environment testing by replicating system behaviors, facilitating scenario analysis without physical risks, though they often lack real-time data integration, limiting accuracy over time. Digital twins provide dynamic, real-time synchronization with physical counterparts, enabling predictive maintenance and operational optimization, but require high data acquisition costs and complex infrastructure. Both technologies enhance decision-making but differ in adaptability and lifecycle fidelity, with simulation models excelling in early-stage design and digital twins driving continuous performance improvement.

Future Trends in Simulation and Digital Twin Technologies

Future trends in simulation and digital twin technologies emphasize enhanced integration with artificial intelligence and machine learning to improve predictive accuracy and real-time decision-making. The adoption of edge computing and 5G connectivity accelerates data processing speeds, enabling more responsive and scalable digital twin implementations across industries such as manufacturing, healthcare, and smart cities. Advancements in immersive technologies like augmented reality facilitate more intuitive visualization and interaction with simulation models and digital twins, driving innovation in design, maintenance, and operational efficiency.

Simulation Model vs Digital Twin Infographic

libmatt.com

libmatt.com