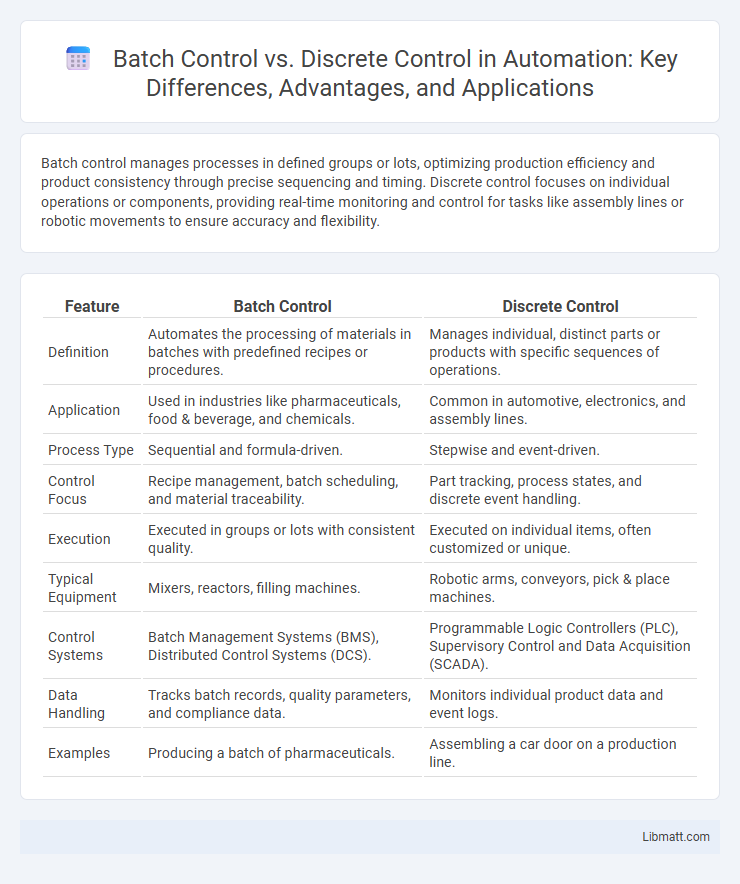

Batch control manages processes in defined groups or lots, optimizing production efficiency and product consistency through precise sequencing and timing. Discrete control focuses on individual operations or components, providing real-time monitoring and control for tasks like assembly lines or robotic movements to ensure accuracy and flexibility.

Table of Comparison

| Feature | Batch Control | Discrete Control |

|---|---|---|

| Definition | Automates the processing of materials in batches with predefined recipes or procedures. | Manages individual, distinct parts or products with specific sequences of operations. |

| Application | Used in industries like pharmaceuticals, food & beverage, and chemicals. | Common in automotive, electronics, and assembly lines. |

| Process Type | Sequential and formula-driven. | Stepwise and event-driven. |

| Control Focus | Recipe management, batch scheduling, and material traceability. | Part tracking, process states, and discrete event handling. |

| Execution | Executed in groups or lots with consistent quality. | Executed on individual items, often customized or unique. |

| Typical Equipment | Mixers, reactors, filling machines. | Robotic arms, conveyors, pick & place machines. |

| Control Systems | Batch Management Systems (BMS), Distributed Control Systems (DCS). | Programmable Logic Controllers (PLC), Supervisory Control and Data Acquisition (SCADA). |

| Data Handling | Tracks batch records, quality parameters, and compliance data. | Monitors individual product data and event logs. |

| Examples | Producing a batch of pharmaceuticals. | Assembling a car door on a production line. |

Introduction to Batch and Discrete Control

Batch control manages processes where materials are combined and transformed in fixed quantities, ideal for industries like pharmaceuticals and food production. Discrete control operates systems with individual, countable units, common in manufacturing assembly lines and robotics. Choosing the right control system enhances your operational efficiency by aligning with specific production needs.

Defining Batch Control: Key Features

Batch control is a process control method used to manage the production of goods in distinct groups, or batches, ensuring precise sequences of operations and recipe consistency. Key features include recipe management, sequencing of steps, real-time monitoring, and data logging for quality assurance and traceability. This control approach enhances flexibility and efficiency, particularly in industries like pharmaceuticals, food processing, and chemicals.

Defining Discrete Control: Key Features

Discrete control systems manage distinct, separate states or events, typically characterized by binary or multi-state signals such as ON/OFF or open/closed conditions. Key features include event-driven operation, logical decision-making, and sequential step execution, often implemented using programmable logic controllers (PLCs) or relay logic. These systems excel in applications requiring precise control over individual components, such as robotics, assembly lines, and packaging processes.

Core Differences Between Batch and Discrete Control

Batch control manages production processes by handling groups of materials or products in specific quantities, emphasizing sequence, timing, and recipe execution. Discrete control operates individual units or items, focusing on start-stop control, positioning, and real-time interaction with machines or components. Your choice depends on whether your process demands coordinated batch sequencing or precise unit-level control.

Industry Applications: Batch vs Discrete Control

Batch control systems are extensively used in industries such as pharmaceuticals, food processing, and chemicals where production involves handling ingredients in specific quantities and sequences to create mixtures or formulations. Discrete control finds its primary application in automotive manufacturing, electronics assembly, and packaging industries where precise, individual parts or products are processed and controlled through distinct stages. Understanding the differences between batch and discrete control can help optimize your industry's process flow and improve quality management.

Benefits of Batch Control Systems

Batch control systems offer precise management of complex production processes by automating recipe-driven operations, ensuring consistent quality and reducing waste. These systems enhance traceability and compliance with industry regulations, making them ideal for pharmaceuticals and food manufacturing. Your facility benefits from improved efficiency and flexibility when adjusting batch sizes or formulations, minimizing downtime and operational costs.

Advantages of Discrete Control Systems

Discrete control systems offer precise management of individual components, enabling enhanced flexibility and simplicity in applications where binary or on/off operations dominate. Their straightforward design reduces complexity and maintenance costs, making them ideal for automated processes requiring fast response times and high reliability. The scalability and ease of programming discrete systems facilitate quick adaptation to changing production requirements, improving operational efficiency.

Challenges and Limitations of Each Control Type

Batch control faces challenges in managing complex recipes and ensuring consistency across variable production cycles, often struggling with scalability and real-time adjustments. Discrete control systems are limited by their rigid structure, making them less adaptable to changes and prone to faults when handling diverse or unpredictable tasks. Understanding these limitations helps optimize Your process automation strategy by selecting the most suitable control approach for specific operational needs.

Selecting the Right Control System for Your Process

Selecting the right control system for your process depends on the nature of production; batch control is ideal for processes requiring sequential operations with variable recipes, such as pharmaceuticals or food manufacturing, ensuring precise mixing and timing. Discrete control suits applications involving distinct, individual parts or tasks, like assembly lines or packaging, where on/off logic and discrete signals dominate operations. Understanding process requirements, cycle complexity, and scalability needs guides optimal system choice, enhancing efficiency and product quality.

Future Trends in Batch and Discrete Control Technologies

Future trends in batch and discrete control technologies emphasize increased integration of AI-driven automation and real-time data analytics to enhance process flexibility and efficiency. Advances in Industry 4.0 and IoT are driving the development of smart controllers capable of adaptive decision-making and predictive maintenance. The convergence of digital twins and cloud computing is also shaping more responsive and scalable control systems across manufacturing sectors.

Batch Control vs Discrete Control Infographic

libmatt.com

libmatt.com