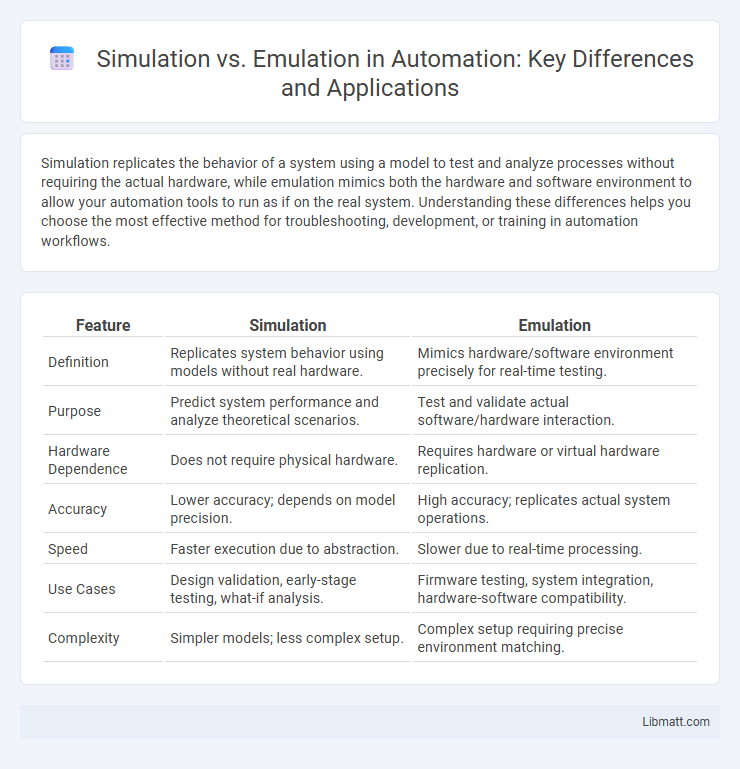

Simulation replicates the behavior of a system using a model to test and analyze processes without requiring the actual hardware, while emulation mimics both the hardware and software environment to allow your automation tools to run as if on the real system. Understanding these differences helps you choose the most effective method for troubleshooting, development, or training in automation workflows.

Table of Comparison

| Feature | Simulation | Emulation |

|---|---|---|

| Definition | Replicates system behavior using models without real hardware. | Mimics hardware/software environment precisely for real-time testing. |

| Purpose | Predict system performance and analyze theoretical scenarios. | Test and validate actual software/hardware interaction. |

| Hardware Dependence | Does not require physical hardware. | Requires hardware or virtual hardware replication. |

| Accuracy | Lower accuracy; depends on model precision. | High accuracy; replicates actual system operations. |

| Speed | Faster execution due to abstraction. | Slower due to real-time processing. |

| Use Cases | Design validation, early-stage testing, what-if analysis. | Firmware testing, system integration, hardware-software compatibility. |

| Complexity | Simpler models; less complex setup. | Complex setup requiring precise environment matching. |

Introduction to Simulation and Emulation in Automation

Simulation in automation replicates the behavior of real systems through software models, allowing you to test processes and predict outcomes without physical equipment. Emulation, however, involves mimicking the exact functionality of hardware or software systems in real-time, often using specialized devices to interface with actual control systems. Understanding the differences between simulation and emulation helps optimize testing strategies and improve system validation in automation projects.

Defining Simulation: Concepts and Applications

Simulation in automation involves creating a virtual model of a real system to study its behavior under various conditions without physical implementation. It allows you to test processes, control algorithms, and system responses by mimicking real-world operations using software tools. Common applications include design validation, performance analysis, and operator training in manufacturing and robotics.

Understanding Emulation: Key Principles and Uses

Emulation in automation replicates the behavior and functions of hardware or software environments to test systems under realistic conditions without requiring physical components. Key principles include mimicking exact system responses and timing, allowing your automation processes to behave as if running on actual devices. Emulation is widely used for validating embedded systems, software compatibility, and performance in complex automation workflows.

Core Differences Between Simulation and Emulation

Simulation replicates the behavior of a system using a model that mimics its functionality, allowing testing without requiring the actual hardware or software. Emulation reproduces both the hardware and software environment, enabling your system to operate as if it were running on the original platform. The core difference lies in simulation's focus on behavior accuracy versus emulation's emphasis on exact environment replication.

Advantages of Simulation in Automation Systems

Simulation in automation systems offers significant advantages such as cost-effective testing and validation of control algorithms without risking physical equipment damage. You can identify and rectify design flaws early by replicating real-world conditions in a virtual environment, which accelerates development cycles and improves system reliability. This approach also enables the optimization of processes and performance analysis under various scenarios, enhancing overall automation efficiency.

Benefits of Emulation for Automation Testing

Emulation in automation testing enables precise replication of hardware and software environments, allowing Your tests to run in conditions identical to production systems. This results in increased accuracy and reliability by detecting issues that may not appear in simulated environments. Emulation also supports continuous integration by providing faster feedback loops and reducing dependency on physical devices, enhancing overall testing efficiency.

Use Cases: When to Choose Simulation vs Emulation

Simulation is ideal for early-stage testing of automation systems where you need to model processes and predict outcomes without physical hardware, making it suitable for design validation and training environments. Emulation is preferred when you require a real-time, hardware-level replica to test software compatibility and performance on actual control systems before deployment. Your choice depends on whether you prioritize cost-effective process evaluation (simulation) or precise hardware interaction testing (emulation).

Impact on Development Speed and Cost Efficiency

Simulation in automation accelerates development speed by allowing virtual testing of systems without physical hardware, significantly reducing upfront costs and minimizing risks. Emulation, while more resource-intensive, provides a highly accurate replication of hardware behavior, enabling more precise debugging and validation but at a higher cost and longer setup time. Balancing simulation's rapid prototyping benefits with emulation's detailed fidelity optimizes overall development efficiency and cost management in automated system design.

Common Challenges and Limitations

Simulation and emulation in automation face challenges such as fidelity and accuracy, where simulations may oversimplify system behavior leading to less precise predictions, while emulations require complex hardware or software replication that can be costly and time-consuming. Both approaches struggle with scalability issues, as simulating or emulating large, complex systems demands significant computational resources and may not fully capture real-world interactions. Limitations also include difficulty in handling real-time constraints and integration with actual devices, which can impact the reliability of automation testing and development processes.

Future Trends in Simulation and Emulation Technologies

Future trends in simulation and emulation technologies in automation emphasize increased integration of artificial intelligence and machine learning to enhance predictive capabilities and real-time decision-making accuracy. Virtual and augmented reality are rapidly advancing, offering immersive simulation environments that improve the training and testing of automated systems. Your automation strategies will benefit from these innovations by achieving higher efficiency and reliability in system validation and performance optimization.

Simulation vs Emulation (in automation) Infographic

libmatt.com

libmatt.com