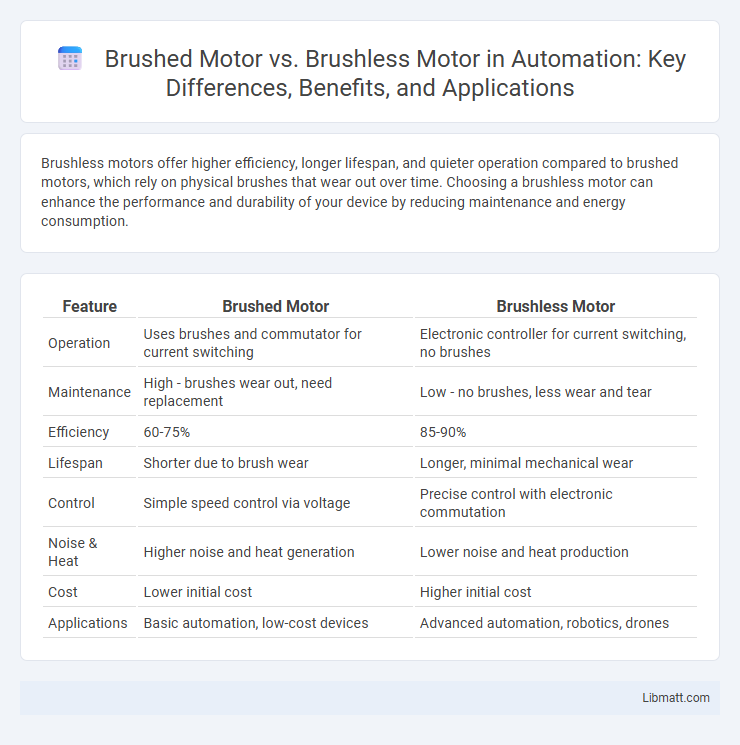

Brushless motors offer higher efficiency, longer lifespan, and quieter operation compared to brushed motors, which rely on physical brushes that wear out over time. Choosing a brushless motor can enhance the performance and durability of your device by reducing maintenance and energy consumption.

Table of Comparison

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Operation | Uses brushes and commutator for current switching | Electronic controller for current switching, no brushes |

| Maintenance | High - brushes wear out, need replacement | Low - no brushes, less wear and tear |

| Efficiency | 60-75% | 85-90% |

| Lifespan | Shorter due to brush wear | Longer, minimal mechanical wear |

| Control | Simple speed control via voltage | Precise control with electronic commutation |

| Noise & Heat | Higher noise and heat generation | Lower noise and heat production |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Basic automation, low-cost devices | Advanced automation, robotics, drones |

Introduction to Brushed and Brushless Motors

Brushed motors use carbon brushes to conduct electricity between stationary wires and the rotating armature, making them simpler but prone to wear and maintenance. Brushless motors eliminate brushes by using electronic controllers to switch current in the motor windings, resulting in higher efficiency, longer lifespan, and quieter operation. These fundamental differences impact performance, reliability, and application suitability in industries like robotics, electric vehicles, and drones.

How Brushed Motors Work

Brushed motors operate using a commutator and brushes that deliver electric current to the rotating armature, creating a magnetic field that interacts with fixed magnets to generate motion. The brushes conduct electricity by maintaining contact with the commutator segments, allowing the motor to spin and produce torque. This mechanical design simplifies control but causes wear and requires maintenance compared to brushless motors.

How Brushless Motors Work

Brushless motors operate using electronic commutation instead of brushes, where a controller switches current through the motor windings to generate a rotating magnetic field. Sensors or sensorless algorithms monitor rotor position to precisely time the current flow, eliminating friction and wear associated with brushes. This results in higher efficiency, longer lifespan, and quieter operation compared to brushed motors.

Efficiency Comparison

Brushless motors typically offer higher efficiency than brushed motors due to their reduced friction and electrical losses, resulting in longer battery life and better performance. Brushed motors have mechanical brushes that cause energy loss through heat and wear, lowering overall efficiency. Your choice of motor impacts energy consumption, with brushless motors providing superior efficiency for demanding applications.

Durability and Maintenance

Brushless motors offer significantly higher durability due to the absence of brushes, which eliminates friction-related wear and reduces the need for frequent replacements. Brushed motors require regular maintenance such as brush replacement and commutator cleaning, which can lead to increased downtime and operational costs. The sealed design of brushless motors protects internal components from dust and debris, enhancing longevity and reducing maintenance efforts compared to brushed counterparts.

Performance and Power Output

Brushless motors deliver higher performance and power output due to their efficient electronic commutation, allowing for greater torque and speed control compared to brushed motors that rely on mechanical brushes. The absence of brushes in brushless motors reduces friction and electrical losses, resulting in longer lifespan and consistent power delivery under load. Brushed motors often experience performance degradation from brush wear and heat buildup, limiting their power output and overall efficiency.

Cost Differences

Brushed motors generally have lower upfront costs due to their simpler design and manufacturing process, making them economical for basic applications. Brushless motors, while more expensive initially due to advanced electronics and construction, offer greater efficiency, longevity, and reduced maintenance expenses over time. The total cost of ownership often favors brushless motors in high-performance or long-term use despite their higher initial price.

Application Areas: Where Each Motor Excels

Brushed motors excel in simple applications like household appliances, toys, and automotive starters due to their low cost and ease of control. Brushless motors dominate in high-performance fields such as drones, electric vehicles, and computer cooling systems, offering greater efficiency, reliability, and longer lifespan. Your choice depends on the specific power, durability, and maintenance requirements of the application area.

Pros and Cons of Brushed Motors

Brushed motors feature simple construction, low initial cost, and straightforward speed control, making them ideal for budget-sensitive applications and easy maintenance. Their main drawbacks include higher wear rates due to brush friction, increased electrical noise, and lower efficiency compared to brushless motors. These factors limit their lifespan and performance in high-demand or precision environments.

Pros and Cons of Brushless Motors

Brushless motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed motors due to the absence of brushes that wear out over time. They generate less noise, produce less heat, and provide better speed and torque control, making them ideal for precision applications. However, brushless motors can be more expensive and require complex electronic controllers, which may increase the overall cost and complexity of your system.

Brushed Motor vs Brushless Motor Infographic

libmatt.com

libmatt.com