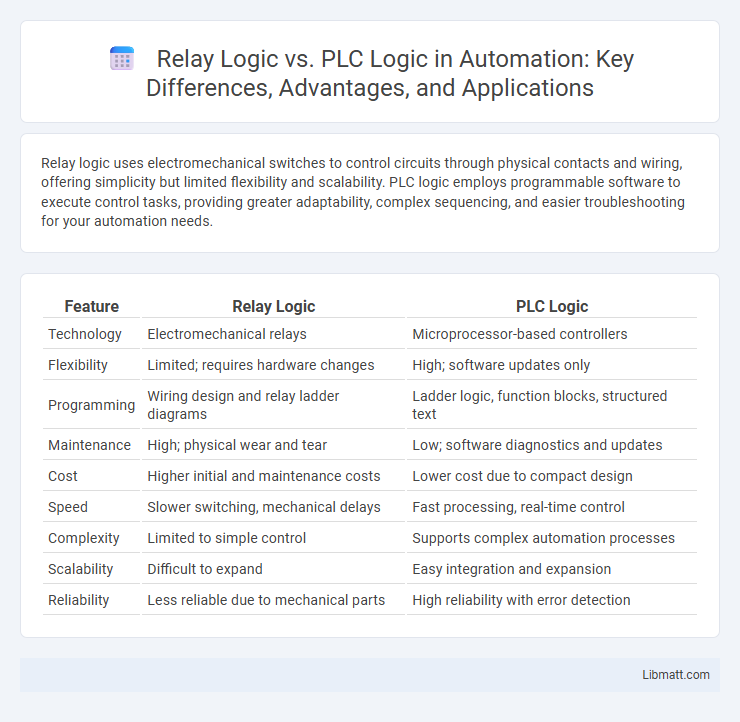

Relay logic uses electromechanical switches to control circuits through physical contacts and wiring, offering simplicity but limited flexibility and scalability. PLC logic employs programmable software to execute control tasks, providing greater adaptability, complex sequencing, and easier troubleshooting for your automation needs.

Table of Comparison

| Feature | Relay Logic | PLC Logic |

|---|---|---|

| Technology | Electromechanical relays | Microprocessor-based controllers |

| Flexibility | Limited; requires hardware changes | High; software updates only |

| Programming | Wiring design and relay ladder diagrams | Ladder logic, function blocks, structured text |

| Maintenance | High; physical wear and tear | Low; software diagnostics and updates |

| Cost | Higher initial and maintenance costs | Lower cost due to compact design |

| Speed | Slower switching, mechanical delays | Fast processing, real-time control |

| Complexity | Limited to simple control | Supports complex automation processes |

| Scalability | Difficult to expand | Easy integration and expansion |

| Reliability | Less reliable due to mechanical parts | High reliability with error detection |

Introduction to Relay Logic and PLC Logic

Relay Logic uses electromechanical relays to control circuits through physical switches and contacts, creating a tangible and straightforward approach to automation. PLC Logic employs programmable logic controllers, allowing for flexible, software-based control that can easily adapt to complex and changing processes. Your choice between these systems impacts scalability, maintenance, and integration with modern industrial automation technologies.

Historical Overview of Relay Logic

Relay Logic, developed in the early 20th century, was the foundational technology for industrial control systems using electromechanical relays to perform logic functions. This approach dominated manufacturing automation until the 1960s when Programmable Logic Controllers (PLCs) emerged, offering more flexible, programmable solutions. Understanding this historical evolution helps you appreciate how modern PLC logic improved control reliability, scalability, and efficiency over traditional relay-based systems.

Evolution and Emergence of PLC Logic

Relay logic, relying on electromagnetic relays for control functions, dominated industrial automation until the late 20th century. The emergence of Programmable Logic Controllers (PLCs) revolutionized automation by replacing hard-wired relay control with flexible, software-based logic that simplified complex process management and troubleshooting. PLC logic evolved from early microprocessors and real-time programming languages, enabling scalable, reliable, and programmable control systems fundamental to modern manufacturing and industrial processes.

Key Components of Relay Logic Systems

Relay logic systems primarily consist of electromechanical relays, contacts, coils, and timers that enable the control of electrical circuits through physical switching. These components interact to perform logical operations by opening and closing contacts based on coil energization, creating a sequence of control actions. Unlike PLC logic that uses programmable software, relay logic relies on hardwired wiring configurations for circuit control and automation tasks.

Core Elements of PLC Logic Systems

PLC logic systems feature core elements such as the processor (CPU), input/output (I/O) modules, and a programming device that allows for flexible control and automation. Unlike relay logic, which relies on physical relays and hardwired connections, PLC logic uses software-based ladder diagrams to simplify complex control sequences. This integration of memory, processing speed, and real-time control enhances efficiency, scalability, and diagnostic capabilities in industrial applications.

Comparative Analysis: Relay Logic vs. PLC Logic

Relay logic employs electromechanical components to control circuits, offering simplicity and robustness but limited flexibility and slower response times. PLC logic utilizes programmable controllers, providing advanced functionality, easy modifications, and real-time diagnostics for complex automation tasks. Your choice depends on application complexity, scalability needs, and maintenance considerations, with PLCs generally preferred for modern industrial control systems.

Advantages and Limitations of Relay Logic

Relay logic offers simplicity and robustness, making it ideal for basic control tasks and environments with high electrical noise. Its advantages include easy troubleshooting with visible wiring and no reliance on complex programming, enhancing reliability in critical applications. However, relay logic has limitations such as limited scalability, higher physical space requirements, and slower response times compared to programmable logic controllers (PLCs).

Benefits and Drawbacks of PLC Logic

PLC logic offers enhanced flexibility and scalability compared to relay logic, enabling complex automation through programmable sequences and easy modifications without hardware changes. It reduces physical wiring, lowers maintenance costs, and allows integration with advanced monitoring and control systems. However, PLCs require initial investment, skilled programming expertise, and may face issues like software bugs or cyber security vulnerabilities.

Real-World Applications of Relay and PLC Logic

Relay logic remains prominent in simple control systems such as motor starters, conveyor belts, and basic lighting circuits due to its reliability and straightforward design. PLC logic dominates complex automation environments like manufacturing assembly lines, process control systems, and advanced robotics because of its flexibility, scalability, and ease of programming. Industrial sectors including automotive, food processing, and chemical plants leverage PLCs for real-time monitoring and adaptive control, while relay logic is favored in smaller, cost-sensitive applications.

Future Trends in Industrial Automation Logic

Future trends in industrial automation logic highlight the shift from relay logic to PLC logic due to increased flexibility, scalability, and integration with IoT and Industry 4.0 technologies. PLC systems offer enhanced diagnostics, remote monitoring, and software-driven adaptability, enabling smarter and more efficient production processes. Growing adoption of edge computing and AI-powered analytics within PLC frameworks will further drive innovation and real-time decision-making in manufacturing environments.

Relay Logic vs PLC Logic Infographic

libmatt.com

libmatt.com