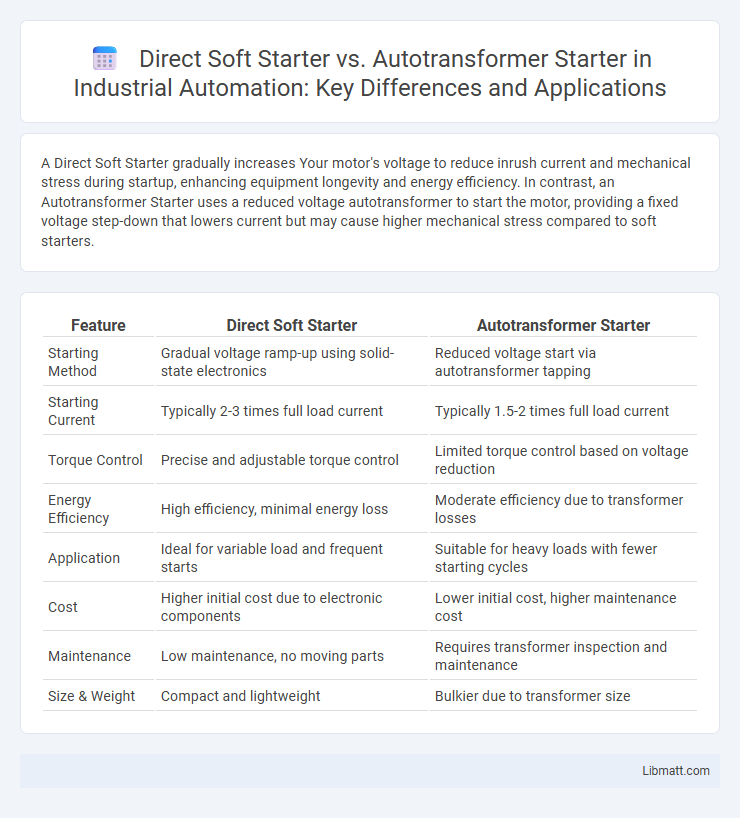

A Direct Soft Starter gradually increases Your motor's voltage to reduce inrush current and mechanical stress during startup, enhancing equipment longevity and energy efficiency. In contrast, an Autotransformer Starter uses a reduced voltage autotransformer to start the motor, providing a fixed voltage step-down that lowers current but may cause higher mechanical stress compared to soft starters.

Table of Comparison

| Feature | Direct Soft Starter | Autotransformer Starter |

|---|---|---|

| Starting Method | Gradual voltage ramp-up using solid-state electronics | Reduced voltage start via autotransformer tapping |

| Starting Current | Typically 2-3 times full load current | Typically 1.5-2 times full load current |

| Torque Control | Precise and adjustable torque control | Limited torque control based on voltage reduction |

| Energy Efficiency | High efficiency, minimal energy loss | Moderate efficiency due to transformer losses |

| Application | Ideal for variable load and frequent starts | Suitable for heavy loads with fewer starting cycles |

| Cost | Higher initial cost due to electronic components | Lower initial cost, higher maintenance cost |

| Maintenance | Low maintenance, no moving parts | Requires transformer inspection and maintenance |

| Size & Weight | Compact and lightweight | Bulkier due to transformer size |

Introduction to Motor Starters

Motor starters, such as Direct Soft Starters and Autotransformer Starters, regulate the initial voltage supplied to an electric motor, controlling torque and current during startup to prevent electrical and mechanical stress. Direct Soft Starters gradually increase voltage through solid-state devices, offering smooth acceleration and reducing wear on your motor. In contrast, Autotransformer Starters use a tapped transformer to decrease voltage in steps, providing robust starting torque but with more complex installation and larger size.

Overview of Direct Soft Starters

Direct Soft Starters provide smooth motor startup by gradually increasing voltage, reducing inrush current and mechanical stress on electrical equipment. They offer precise control over acceleration and deceleration, enhancing equipment longevity and minimizing electrical disturbances. This technology is widely used in applications requiring controlled starting torque and reduced power surges compared to autotransformer starters.

Overview of Autotransformer Starters

Autotransformer starters reduce initial voltage by using a tapped autotransformer to limit inrush current during motor startup, offering smoother acceleration and decreased mechanical stress compared to direct on-line starting. This method improves energy efficiency and extends motor life by controlling starting torque more precisely. Your industrial applications benefit from enhanced reliability and reduced electrical disturbances with autotransformer starters.

Working Principle: Direct Soft Starter

A Direct Soft Starter works by gradually increasing the voltage supplied to an electric motor, enabling a smooth ramp-up in speed and torque without causing sudden electrical or mechanical stress. It employs thyristors or silicon-controlled rectifiers (SCRs) to modulate the voltage during startup, reducing inrush current and providing controlled acceleration. This method enhances motor longevity and reduces energy consumption compared to traditional direct-on-line starting methods.

Working Principle: Autotransformer Starter

The autotransformer starter operates by initially reducing the voltage supplied to the motor through an autotransformer, which limits the starting current and torque. This method allows the motor to start smoothly under a reduced voltage and then gradually transitions to full voltage as the motor reaches a certain speed. Your motor experiences lower electrical and mechanical stress during startup, enhancing overall efficiency and lifespan.

Key Differences Between Direct Soft Starter and Autotransformer Starter

Direct Soft Starters regulate motor voltage gradually to reduce inrush current and torque during startup, enhancing smooth acceleration and minimizing mechanical stress. Autotransformer Starters use reduced voltage through an autotransformer to limit starting current, providing a fixed voltage reduction ratio but with less precise control over motor acceleration. Your choice depends on the need for precise voltage control and smoother starts (favoring direct soft starters) versus cost-effective reduced voltage starting with simpler design (favoring autotransformer starters).

Advantages of Direct Soft Starters

Direct soft starters provide precise control over motor starting current, significantly reducing mechanical stress and electrical disturbances compared to autotransformer starters. Their compact design eliminates the need for bulky transformers, leading to easier installation and lower maintenance costs. Soft starters also enable smooth acceleration and deceleration, enhancing equipment lifespan and improving process efficiency in various industrial applications.

Advantages of Autotransformer Starters

Autotransformer starters provide reduced starting current and smooth acceleration, significantly lowering mechanical stress on motors and electrical networks. Their voltage regulation capability enhances starting torque control, improving motor performance and extending equipment lifespan. Compared to direct soft starters, autotransformer starters offer better energy efficiency and reduced power loss during motor startup.

Application Scenarios for Each Starter

Direct Soft Starters are ideal for applications requiring smooth acceleration and deceleration, such as conveyors, pumps, and fans, where minimizing mechanical stress and electrical peak currents is crucial. Autotransformer Starters suit heavy-duty industrial machines like large compressors, crushers, and crushers, where reduced starting current and high starting torque are necessary. Choosing the appropriate starter depends on the load type, starting torque requirements, and electrical system constraints.

Choosing the Right Starter: Factors to Consider

Selecting the appropriate starter between Direct Soft Starter and Autotransformer Starter depends on key factors like motor size, starting current limitations, and application requirements. Direct Soft Starters offer gradual voltage ramp-up to minimize mechanical stress and electrical surges, ideal for sensitive equipment, while Autotransformer Starters reduce starting current by using tapped transformers, suited for larger motors with high starting torque demands. Assessing load characteristics, energy efficiency, and installation cost ensures optimal performance and system longevity.

Direct Soft Starter vs Autotransformer Starter Infographic

libmatt.com

libmatt.com