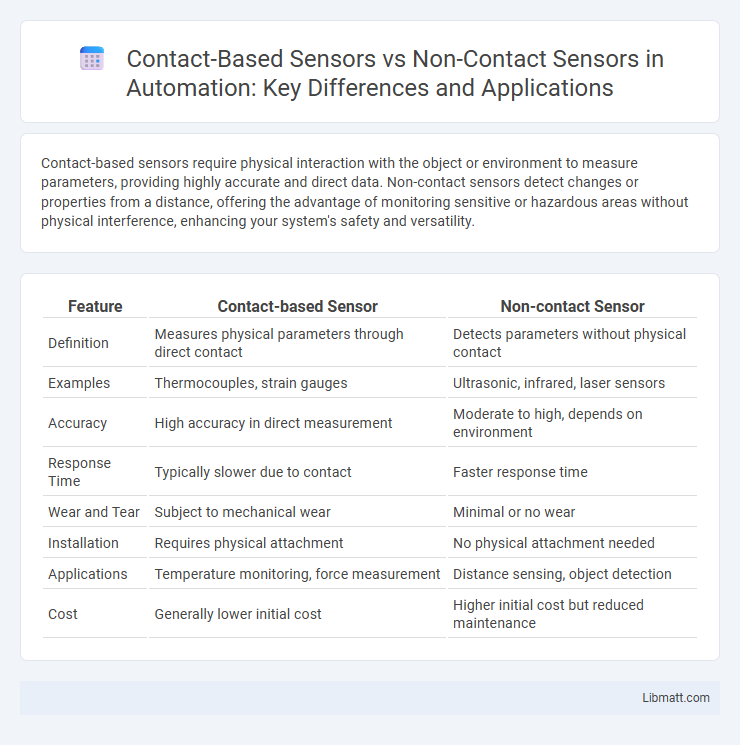

Contact-based sensors require physical interaction with the object or environment to measure parameters, providing highly accurate and direct data. Non-contact sensors detect changes or properties from a distance, offering the advantage of monitoring sensitive or hazardous areas without physical interference, enhancing your system's safety and versatility.

Table of Comparison

| Feature | Contact-based Sensor | Non-contact Sensor |

|---|---|---|

| Definition | Measures physical parameters through direct contact | Detects parameters without physical contact |

| Examples | Thermocouples, strain gauges | Ultrasonic, infrared, laser sensors |

| Accuracy | High accuracy in direct measurement | Moderate to high, depends on environment |

| Response Time | Typically slower due to contact | Faster response time |

| Wear and Tear | Subject to mechanical wear | Minimal or no wear |

| Installation | Requires physical attachment | No physical attachment needed |

| Applications | Temperature monitoring, force measurement | Distance sensing, object detection |

| Cost | Generally lower initial cost | Higher initial cost but reduced maintenance |

Introduction to Contact-Based and Non-Contact Sensors

Contact-based sensors rely on physical interaction with the object or environment to measure parameters like temperature, pressure, or force, providing direct and precise readings essential in industrial automation and quality control. Non-contact sensors detect properties without physical contact, using technologies such as infrared, ultrasonic, or laser, which enables measurement of hazardous, moving, or delicate objects. Applications of contact-based sensors include tactile feedback and direct measurement, while non-contact sensors excel in scenarios requiring distance measurement, speed detection, or real-time monitoring in inaccessible locations.

Definitions: What Are Contact-Based Sensors?

Contact-based sensors detect physical changes through direct interaction with the object or surface, measuring parameters like pressure, temperature, or displacement by maintaining physical contact. These sensors are commonly used in applications where precise tactile feedback or direct measurement is essential, such as in touchscreens, thermocouples, and strain gauges. Your choice of a contact-based sensor depends on the need for accurate data collection through direct physical engagement with the monitored environment.

Definitions: What Are Non-Contact Sensors?

Non-contact sensors are devices that detect physical properties or changes without direct physical contact with the object or environment, often using methods like optical, ultrasonic, or electromagnetic technologies. These sensors are essential in applications requiring hygiene, high-speed measurements, or delicate surface monitoring, such as in industrial automation, medical diagnostics, and quality control. Understanding your system's needs can help determine whether a non-contact sensor offers the precision and safety advantages over traditional contact-based sensors.

How Contact-Based Sensors Work

Contact-based sensors operate by directly interacting with the object or environment they measure, translating physical changes such as pressure, temperature, or displacement into electrical signals. These sensors rely on physical contact to detect variations in mechanical or thermal properties, enabling precise measurement critical in applications like touchscreens, medical devices, and industrial machinery. Your device's accuracy and responsiveness depend on the sensor's ability to maintain consistent contact and accurately transduce the physical interaction into reliable data.

How Non-Contact Sensors Operate

Non-contact sensors detect physical properties or changes without direct physical interaction, primarily using electromagnetic fields, light, sound, or magnetic fields to sense objects or environmental conditions. They operate by emitting waves or signals, such as infrared, ultrasonic, or laser beams, which reflect, refract, or absorb upon encountering a target, allowing the sensor to measure variables like distance, temperature, or motion accurately. These sensors are widely used in industrial automation, robotics, and safety systems due to their ability to monitor delicate or hazardous environments without wear and tear.

Key Differences Between Contact and Non-Contact Sensors

Contact-based sensors require physical interaction with the object or environment to measure parameters such as temperature, pressure, or force, providing direct and accurate readings. Non-contact sensors, like infrared thermometers or ultrasonic sensors, detect measurements without touching the object, enabling safer and faster data acquisition in hazardous or hard-to-reach areas. Your choice between these sensor types depends on application-specific factors such as accuracy, response time, and environmental conditions.

Advantages of Contact-Based Sensors

Contact-based sensors offer higher accuracy and reliability by directly measuring physical parameters through touch or pressure, making them ideal for applications requiring precise data such as temperature, strain, or force measurements. These sensors typically have lower susceptibility to environmental interference like dust, humidity, or electromagnetic noise compared to non-contact sensors. Their straightforward design often results in cost-effective implementation and easier integration into existing mechanical systems.

Advantages of Non-Contact Sensors

Non-contact sensors offer significant advantages including the elimination of physical wear and tear since they do not require direct interaction with the measured object, ensuring longer sensor lifespan and reduced maintenance costs. They enable precise measurements in hazardous or hard-to-reach environments where contact sensors would be impractical or unsafe. Furthermore, non-contact sensors provide higher measurement speed and can detect properties such as temperature, displacement, or presence without influencing the target object's condition.

Typical Applications for Both Sensor Types

Contact-based sensors are commonly used in industrial automation for machine condition monitoring, robotics for precise position detection, and medical devices to measure physiological parameters through direct contact. Non-contact sensors find typical applications in security systems utilizing motion detection, environmental monitoring through infrared temperature sensing, and automotive safety features such as proximity detection and collision avoidance. Your choice between these sensor types depends on application requirements like the need for direct interaction or remote sensing capabilities.

Choosing the Right Sensor: Factors to Consider

Choosing the right sensor depends on factors such as measurement accuracy, environmental conditions, and application requirements. Contact-based sensors provide direct measurements with high precision but may wear out or affect the object, while non-contact sensors offer versatility and safety in harsh or delicate environments. Your decision should balance durability, response time, and the nature of the measurement target for optimal performance.

Contact-based Sensor vs Non-contact Sensor Infographic

libmatt.com

libmatt.com