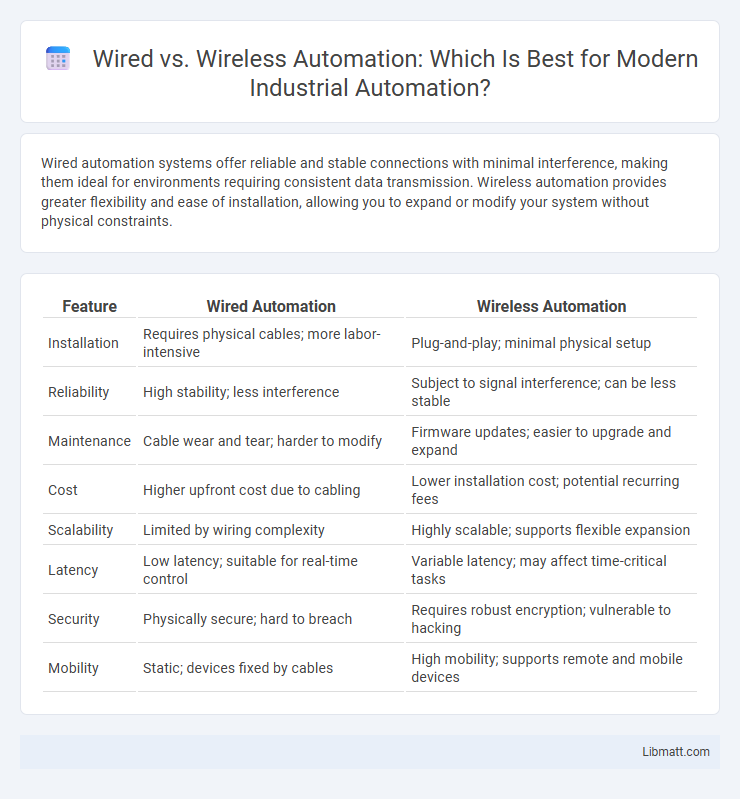

Wired automation systems offer reliable and stable connections with minimal interference, making them ideal for environments requiring consistent data transmission. Wireless automation provides greater flexibility and ease of installation, allowing you to expand or modify your system without physical constraints.

Table of Comparison

| Feature | Wired Automation | Wireless Automation |

|---|---|---|

| Installation | Requires physical cables; more labor-intensive | Plug-and-play; minimal physical setup |

| Reliability | High stability; less interference | Subject to signal interference; can be less stable |

| Maintenance | Cable wear and tear; harder to modify | Firmware updates; easier to upgrade and expand |

| Cost | Higher upfront cost due to cabling | Lower installation cost; potential recurring fees |

| Scalability | Limited by wiring complexity | Highly scalable; supports flexible expansion |

| Latency | Low latency; suitable for real-time control | Variable latency; may affect time-critical tasks |

| Security | Physically secure; hard to breach | Requires robust encryption; vulnerable to hacking |

| Mobility | Static; devices fixed by cables | High mobility; supports remote and mobile devices |

Introduction to Wired vs Wireless Automation

Wired automation systems rely on physical cables to connect devices, offering reliable and high-speed communication essential for industrial environments requiring minimal interference. Wireless automation uses radio frequency or other wireless technologies to facilitate flexible and scalable connectivity, ideal for remote or hard-to-wire locations. Your choice between wired and wireless automation depends on factors like installation complexity, environmental conditions, and data transmission needs.

Key Differences Between Wired and Wireless Automation

Wired automation systems rely on physical cables for data transmission, offering consistent signal quality, high security, and low latency essential for critical industrial processes. Wireless automation provides greater flexibility, easier installation, and scalability, making it ideal for dynamic environments where mobility and rapid deployment are priorities. Your choice between wired and wireless automation should consider factors like installation complexity, environmental interference, and the need for real-time data transfer.

Advantages of Wired Automation Systems

Wired automation systems offer superior reliability and minimal interference, ensuring consistent performance in industrial environments. They provide enhanced security by reducing the risk of unauthorized access or signal hacking compared to wireless systems. Your operations benefit from stable, high-speed data transmission and lower latency, critical for precise control and monitoring.

Benefits of Wireless Automation Technologies

Wireless automation technologies offer unparalleled flexibility by enabling easy installation and expansion without the constraints of physical wiring. These systems significantly reduce maintenance costs and downtime due to fewer hardware failures and simplified troubleshooting. You benefit from enhanced scalability and remote monitoring capabilities, optimizing operational efficiency in diverse industrial and commercial environments.

Installation and Maintenance Considerations

Wired automation systems require extensive installation involving physical cables, conduits, and structured wiring, making initial setup more labor-intensive and potentially disruptive. Maintenance for wired systems often demands inspecting and repairing hard-to-access cables, increasing downtime and costs, whereas wireless automation offers simpler installation with minimal infrastructure and easier maintenance through remote diagnostics and software updates. Your choice impacts installation time, maintenance complexity, and long-term operational efficiency based on the specific environment and scalability needs.

Cost Comparison: Wired vs Wireless Solutions

Wired automation systems generally involve higher upfront costs due to extensive cabling, installation labor, and material expenses, but offer reliable long-term stability and minimal interference. Wireless solutions reduce installation costs significantly by eliminating physical cables and allow for flexible deployment, though they may require investment in signal repeaters or security measures to ensure consistent performance. Choosing the right solution impacts your overall budget, balancing initial expenses against maintenance and scalability needs.

Security and Reliability Factors

Wired automation systems offer higher security and reliability due to physical connections that minimize interference and unauthorized access risks. Wireless automation provides flexibility and ease of installation but is more vulnerable to signal disruptions, hacking, and environmental interferences. Advanced encryption protocols and robust network designs are critical to enhance wireless security and ensure dependable performance comparable to wired setups.

Scalability and Future-Proofing

Wired automation systems offer limited scalability due to physical constraints and higher installation costs, making future expansions more complex and less flexible. Wireless automation enhances scalability by enabling easy addition of devices and seamless integration without extensive infrastructure changes. Future-proofing is stronger in wireless solutions, as they support rapid upgrades and integration with emerging IoT technologies, ensuring adaptability in evolving industrial environments.

Best Use Cases for Wired vs Wireless Automation

Wired automation systems excel in environments requiring high reliability, low latency, and robust security, such as industrial manufacturing plants and critical infrastructure control. Wireless automation suits flexible, large-scale deployments like smart homes, agricultural monitoring, and temporary installations where mobility and ease of installation are prioritized. Your choice between wired and wireless automation should consider factors like environmental interference, installation costs, and maintenance requirements to optimize system performance.

Choosing the Right Solution for Your Needs

Choosing the right automation solution depends on factors like reliability, installation complexity, and scalability. Wired automation offers stable connections and lower interference, ideal for environments requiring consistent performance, while wireless automation provides flexibility and ease of installation, suited for dynamic or hard-to-wire locations. Assessing your specific operational needs and infrastructure will help determine whether wired or wireless automation best supports your business goals.

Wired vs Wireless Automation Infographic

libmatt.com

libmatt.com