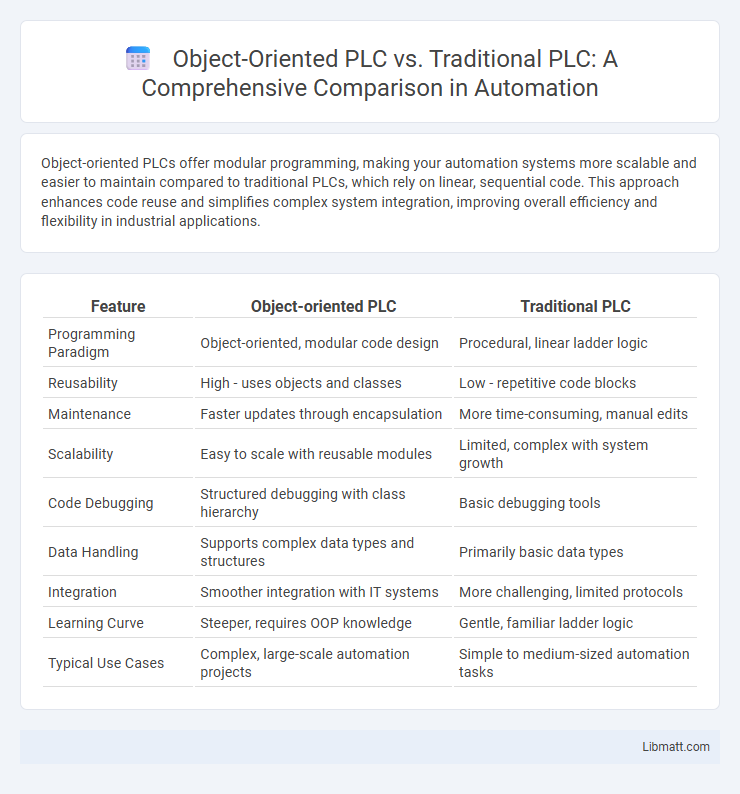

Object-oriented PLCs offer modular programming, making your automation systems more scalable and easier to maintain compared to traditional PLCs, which rely on linear, sequential code. This approach enhances code reuse and simplifies complex system integration, improving overall efficiency and flexibility in industrial applications.

Table of Comparison

| Feature | Object-oriented PLC | Traditional PLC |

|---|---|---|

| Programming Paradigm | Object-oriented, modular code design | Procedural, linear ladder logic |

| Reusability | High - uses objects and classes | Low - repetitive code blocks |

| Maintenance | Faster updates through encapsulation | More time-consuming, manual edits |

| Scalability | Easy to scale with reusable modules | Limited, complex with system growth |

| Code Debugging | Structured debugging with class hierarchy | Basic debugging tools |

| Data Handling | Supports complex data types and structures | Primarily basic data types |

| Integration | Smoother integration with IT systems | More challenging, limited protocols |

| Learning Curve | Steeper, requires OOP knowledge | Gentle, familiar ladder logic |

| Typical Use Cases | Complex, large-scale automation projects | Simple to medium-sized automation tasks |

Introduction to PLC Programming Paradigms

Object-oriented PLC programming introduces modularity, reusability, and scalability by organizing code into classes and objects, enhancing maintenance and reducing errors. Traditional PLC programming relies on sequential logic and predefined instructions, often resulting in complex, monolithic code that can be harder to update. Your development efficiency improves when using object-oriented paradigms, especially in large-scale or complex automation projects.

Overview of Traditional PLC Methodology

Traditional PLC methodology relies on a sequential, step-by-step programming approach using ladder logic or function block diagrams, focusing on discrete control processes. It emphasizes simplicity and ease of troubleshooting due to its linear and modular design, which suits straightforward automation tasks. You may find traditional PLCs highly effective for consistent, repetitive operations but limited in scalability and adaptability compared to object-oriented alternatives.

What is Object-Oriented PLC Programming?

Object-Oriented PLC programming organizes code into reusable objects that encapsulate data and functions, enhancing modularity and scalability in automation systems. Unlike traditional PLC programming, which relies on linear or ladder logic sequences, object-oriented approaches allow advanced features such as inheritance, polymorphism, and encapsulation, leading to easier maintenance and reduced development time. This programming paradigm improves code readability and promotes efficient resource management in complex industrial control applications.

Core Differences: Object-Oriented vs Traditional PLCs

Object-oriented PLCs utilize encapsulation, inheritance, and polymorphism to create modular and reusable code blocks, enhancing scalability and maintainability compared to traditional PLCs. Traditional PLCs rely on sequential logic with fixed function blocks and ladder diagrams, which often result in more rigid and less flexible programming structures. The core difference lies in the ability of object-oriented PLCs to model complex systems through objects, enabling better abstraction and code management.

Benefits of Object-Oriented PLC Programming

Object-oriented PLC programming enhances modularity, reusability, and maintainability by encapsulating functions into objects, leading to more scalable and efficient automation systems. It simplifies complex control processes through inheritance and polymorphism, reducing development time and errors. This approach supports better integration with modern industrial IoT frameworks, improving diagnostics and system flexibility compared to traditional PLC programming.

Limitations of Traditional PLC Approaches

Traditional PLC approaches face limitations such as rigid programming structures, which reduce flexibility and scalability for complex automation tasks. These systems often require extensive rewiring and time-consuming code modifications to accommodate changes, leading to increased downtime and maintenance costs. Your automation projects can benefit from object-oriented PLCs by enabling modular, reusable code and more efficient system upgrades.

Transitioning from Traditional to Object-Oriented PLC

Transitioning from traditional PLC to object-oriented PLC involves restructuring control logic into reusable, modular objects that enhance scalability and maintainability in industrial automation systems. Object-oriented PLC programming leverages encapsulation and inheritance, reducing code redundancy and improving debugging efficiency compared to the linear, sequential instruction sets of traditional PLCs. Effective transition requires retraining engineers on object-oriented principles and selecting PLC platforms that support IEC 61131-3 standards for object-oriented programming.

Real-World Applications and Case Studies

Object-oriented PLCs enable modular programming and reusability, significantly enhancing scalability and maintenance in complex manufacturing systems such as automotive assembly lines and packaging industries. Traditional PLCs remain prevalent in straightforward, repetitive processes like conveyor belt controls and basic machine operations due to their simplicity and well-established reliability. Case studies demonstrate object-oriented PLCs reduce development time by up to 30% and improve fault diagnosis accuracy in smart factories, whereas traditional PLCs continue to be cost-effective for smaller-scale applications with limited customization needs.

Performance and Maintenance Comparison

Object-oriented PLCs enhance performance through modular programming, enabling faster execution and easier scalability compared to traditional PLCs. Maintenance is streamlined with object-oriented PLCs due to reusable code blocks and improved debugging capabilities, reducing downtime and development costs. Traditional PLCs often require more manual intervention for updates and troubleshooting, impacting long-term efficiency and system adaptability.

Future Trends in PLC Programming Paradigms

Future trends in PLC programming paradigms emphasize a shift towards object-oriented PLCs, which enable modularity, reusability, and scalability unlike traditional PLCs relying on ladder logic and function blocks. Object-oriented PLC programming facilitates integration with Industry 4.0 technologies, supporting complex automation systems through encapsulation and inheritance. Advances in IEC 61131-3 standards and enhanced development environments promote adoption of object-oriented techniques, driving greater flexibility and maintainability in industrial automation.

Object-oriented PLC vs Traditional PLC Infographic

libmatt.com

libmatt.com