Point level sensors detect liquid or solid presence at a specific point, providing simple on/off signals ideal for high or low-level alarms. Continuous level sensors measure the entire level range, delivering real-time data for precise monitoring and control of your tank or vessel contents.

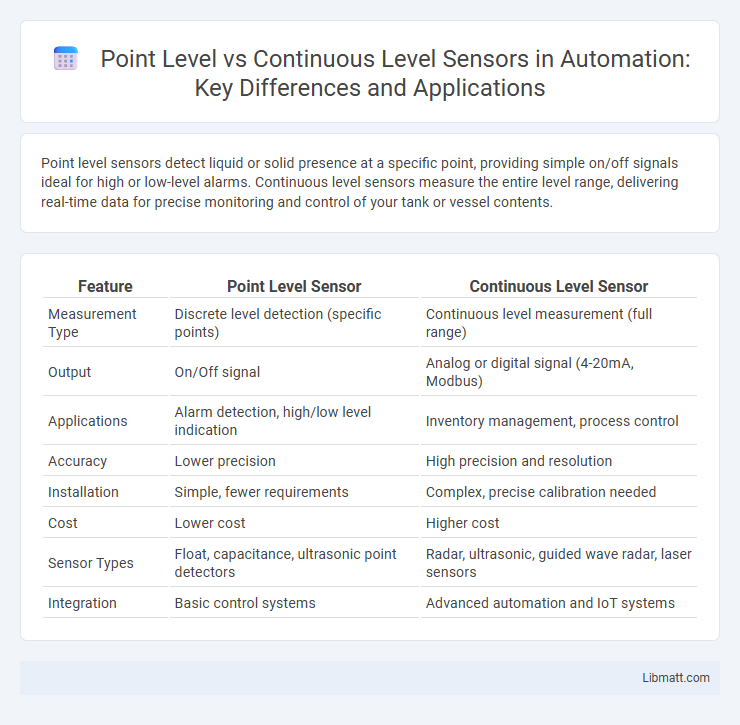

Table of Comparison

| Feature | Point Level Sensor | Continuous Level Sensor |

|---|---|---|

| Measurement Type | Discrete level detection (specific points) | Continuous level measurement (full range) |

| Output | On/Off signal | Analog or digital signal (4-20mA, Modbus) |

| Applications | Alarm detection, high/low level indication | Inventory management, process control |

| Accuracy | Lower precision | High precision and resolution |

| Installation | Simple, fewer requirements | Complex, precise calibration needed |

| Cost | Lower cost | Higher cost |

| Sensor Types | Float, capacitance, ultrasonic point detectors | Radar, ultrasonic, guided wave radar, laser sensors |

| Integration | Basic control systems | Advanced automation and IoT systems |

Understanding Point Level Sensors

Point level sensors detect the presence or absence of a substance at a specific point within a container, providing discrete on/off signals that indicate if the material has reached a predetermined level. Common types include float switches, vibrating forks, and capacitance probes, each suitable for various materials such as liquids, solids, or slurries. These sensors offer reliable and straightforward solutions for level monitoring in applications like tanks, silos, and pipelines where exact level measurement is not required.

What Are Continuous Level Sensors?

Continuous level sensors provide real-time, precise measurement of liquid or solid materials' levels in tanks or containers, enabling constant monitoring without interruption. These sensors utilize technologies such as ultrasonic, radar, or capacitive methods to detect level changes continuously over the entire range, offering high accuracy and detailed data for process control. Unlike point level sensors that trigger at specific thresholds, continuous sensors help optimize inventory management and prevent overflow or dry-run conditions through exact level readings.

Key Differences Between Point and Continuous Level Sensors

Point level sensors detect specific preset levels within a container using discrete signals, making them ideal for alarms and on/off control. Continuous level sensors provide real-time, precise measurement of liquid or solid levels across the entire range, supporting process control and inventory management. Key differences include measurement type, accuracy, application flexibility, and cost, with continuous sensors offering higher precision and complexity compared to point sensors.

Working Principles of Point Level Sensors

Point level sensors operate by detecting the presence or absence of a substance at a specific level using methods such as float switches, capacitive sensors, or ultrasonic waves. These sensors trigger an alert or control action once the material reaches the set point, ensuring precise level detection without continuous monitoring. Your choice of point level sensor depends on factors like liquid type, temperature, and application environment to ensure reliable performance.

How Continuous Level Sensors Operate

Continuous level sensors operate by constantly measuring the level of a substance, such as liquid or granular material, within a container to provide real-time, precise data. These sensors often use technologies like ultrasonic, radar, or capacitance to detect the exact height of the material, enabling accurate monitoring and control. You can rely on continuous level sensors for applications requiring detailed level profiling, improving process efficiency and safety.

Applications of Point Level Sensors

Point level sensors are commonly used in applications requiring precise detection of liquid or solid material at specific levels, such as tank overflow prevention, dry-run protection for pumps, and sump level control. These sensors are ideal for monitoring critical setpoints in industrial processes involving water treatment, food and beverage production, and chemical storage. Your system benefits from their reliability in triggering alarms or control actions at defined fill or empty points, ensuring operational safety and efficiency.

Applications of Continuous Level Sensors

Continuous level sensors are widely used in industries such as water treatment, chemical processing, and oil and gas for real-time monitoring of fluid levels in tanks and vessels. These sensors provide precise measurement of liquid height, enabling automated control systems to maintain optimal process conditions and prevent overflow or dry running. Their ability to deliver constant, accurate data makes them essential for applications requiring dynamic level management and process efficiency.

Advantages and Limitations of Point Level Sensors

Point level sensors offer precise detection of specific liquid levels, making them ideal for applications requiring simple on/off control or alarm signals. These sensors are cost-effective, easy to install, and suitable for detecting high, low, or intermediate levels but lack the ability to provide continuous measurement data. Your choice may be limited by their inability to monitor varying fluid volumes, which continuous level sensors handle with more accuracy and real-time feedback.

Benefits and Drawbacks of Continuous Level Sensors

Continuous level sensors provide precise, real-time measurements of liquid or solid materials, enabling accurate monitoring and control in various industrial applications. Their ability to deliver consistent data over a wide range allows for improved process efficiency and safety, though they typically come with higher initial costs and require more complex installation and maintenance compared to point level sensors. Sensitivity to environmental conditions and potential signal interference can also pose challenges, necessitating careful sensor selection and system design.

Choosing the Right Level Sensor for Your Application

Point level sensors detect specific liquid levels, ideal for overflow prevention, alarm activation, or pump control in tanks and vessels. Continuous level sensors provide real-time monitoring of liquid levels, offering precise measurement for inventory management and process control. Evaluating your application's accuracy requirements, environmental conditions, and budget helps determine whether point or continuous level sensors best suit your needs.

Point Level vs Continuous Level Sensor Infographic

libmatt.com

libmatt.com