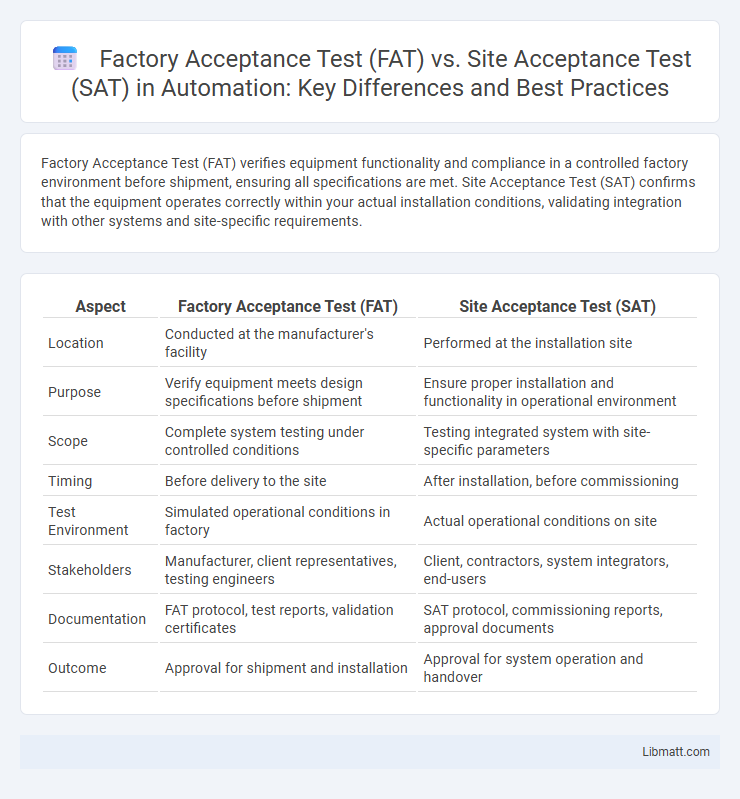

Factory Acceptance Test (FAT) verifies equipment functionality and compliance in a controlled factory environment before shipment, ensuring all specifications are met. Site Acceptance Test (SAT) confirms that the equipment operates correctly within your actual installation conditions, validating integration with other systems and site-specific requirements.

Table of Comparison

| Aspect | Factory Acceptance Test (FAT) | Site Acceptance Test (SAT) |

|---|---|---|

| Location | Conducted at the manufacturer's facility | Performed at the installation site |

| Purpose | Verify equipment meets design specifications before shipment | Ensure proper installation and functionality in operational environment |

| Scope | Complete system testing under controlled conditions | Testing integrated system with site-specific parameters |

| Timing | Before delivery to the site | After installation, before commissioning |

| Test Environment | Simulated operational conditions in factory | Actual operational conditions on site |

| Stakeholders | Manufacturer, client representatives, testing engineers | Client, contractors, system integrators, end-users |

| Documentation | FAT protocol, test reports, validation certificates | SAT protocol, commissioning reports, approval documents |

| Outcome | Approval for shipment and installation | Approval for system operation and handover |

Introduction to FAT and SAT

Factory Acceptance Test (FAT) is a critical quality assurance process conducted at the manufacturer's site to verify equipment performance against design specifications before shipment. Site Acceptance Test (SAT) occurs after installation at the client's location to confirm the system operates correctly under actual site conditions. Both FAT and SAT are essential milestones in project validation ensuring functionality, safety, and compliance with contractual requirements.

Definition of Factory Acceptance Test (FAT)

Factory Acceptance Test (FAT) is a comprehensive evaluation conducted at the manufacturer's facility to verify that equipment or systems meet specified design and performance criteria before shipment. FAT involves functional, operational, and safety testing under controlled conditions, simulating real-world scenarios to identify defects early. This pre-delivery inspection ensures compliance with contract requirements, reduces on-site installation risks, and minimizes project delays.

Definition of Site Acceptance Test (SAT)

Site Acceptance Test (SAT) is a critical phase in the commissioning process where equipment or systems are tested at the installation site to verify functionality, performance, and compliance with specified requirements under real operational conditions. SAT confirms that the system operates correctly within its intended environment, integrating with other site components and infrastructure. This testing ensures readiness for full-scale production or deployment, addressing any site-specific issues before final acceptance.

Key Differences Between FAT and SAT

Factory Acceptance Test (FAT) is conducted at the manufacturer's site to verify that equipment meets design specifications and functions correctly before shipment, ensuring quality control under controlled conditions. Site Acceptance Test (SAT) takes place at the installation site to confirm the system operates properly within the actual environment and integrates seamlessly with existing infrastructure. Your project benefits from FAT by addressing issues early, while SAT validates performance in real-world conditions, minimizing operational risks.

Importance of FAT in Quality Assurance

Factory Acceptance Test (FAT) plays a crucial role in quality assurance by verifying that equipment and systems meet design specifications before delivery to the site. Conducted in a controlled factory environment, FAT allows for early detection and correction of defects, reducing risks of costly modifications during installation. This proactive testing ensures compliance, functionality, and performance, thereby enhancing overall project reliability and client satisfaction.

Role of SAT in Project Commissioning

Site Acceptance Test (SAT) plays a crucial role in project commissioning by verifying that equipment and systems function correctly in the actual operational environment before final handover. SAT ensures integration with existing site infrastructure, confirming performance under real conditions to mitigate risks of failure during full-scale operation. Your successful project commissioning depends on thorough SAT validation to achieve compliance with contract specifications and safety standards.

FAT and SAT: Testing Procedures Compared

Factory Acceptance Test (FAT) involves thorough testing of equipment or systems at the manufacturer's site to verify compliance with design specifications before shipment. Site Acceptance Test (SAT) occurs after installation at the operational location, ensuring the system performs correctly within the actual environment and integrates with existing infrastructure. You benefit from understanding that FAT focuses on pre-shipment validation, while SAT confirms operational functionality and reliability on-site.

Criteria for FAT and SAT Success

Factory Acceptance Test (FAT) success criteria are based on verifying that equipment or systems meet predefined technical specifications and operational requirements under controlled factory conditions before shipment. Site Acceptance Test (SAT) success criteria evaluate the performance, integration, and functionality of the equipment or system in the actual operational environment to ensure it meets the project requirements and contractual obligations. Your project's overall acceptance largely depends on passing both FAT and SAT criteria, ensuring reliability and compliance from factory settings to real-world applications.

Challenges Encountered During FAT and SAT

Challenges encountered during Factory Acceptance Test (FAT) often include limited replication of real-site conditions, leading to potential discrepancies in equipment performance when deployed. Site Acceptance Test (SAT) challenges typically involve environmental variables, unforeseen site-specific issues, and coordinating schedules with multiple stakeholders, which can delay validation and commissioning. Your project timeline may be impacted by the need to address these FAT and SAT challenges to ensure system functionality meets operational requirements.

Best Practices for Conducting FAT and SAT

Factory Acceptance Test (FAT) should be conducted in a controlled environment with predefined test plans, comprehensive checklists, and active involvement of stakeholders to ensure equipment meets design specifications before shipment. Site Acceptance Test (SAT) requires verification of system performance and integration under actual operating conditions, emphasizing coordination with site teams, real-time troubleshooting, and confirmation of compliance with site-specific requirements. Meticulous documentation and clear communication during both FAT and SAT enhance traceability, accountability, and successful project handover.

Factory Acceptance Test (FAT) vs Site Acceptance Test (SAT) Infographic

libmatt.com

libmatt.com