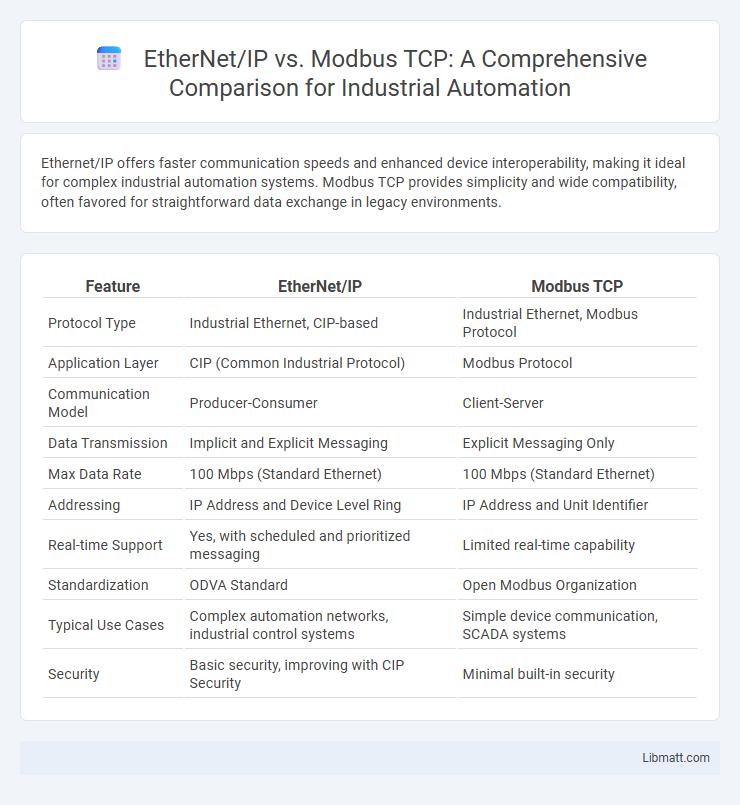

Ethernet/IP offers faster communication speeds and enhanced device interoperability, making it ideal for complex industrial automation systems. Modbus TCP provides simplicity and wide compatibility, often favored for straightforward data exchange in legacy environments.

Table of Comparison

| Feature | EtherNet/IP | Modbus TCP |

|---|---|---|

| Protocol Type | Industrial Ethernet, CIP-based | Industrial Ethernet, Modbus Protocol |

| Application Layer | CIP (Common Industrial Protocol) | Modbus Protocol |

| Communication Model | Producer-Consumer | Client-Server |

| Data Transmission | Implicit and Explicit Messaging | Explicit Messaging Only |

| Max Data Rate | 100 Mbps (Standard Ethernet) | 100 Mbps (Standard Ethernet) |

| Addressing | IP Address and Device Level Ring | IP Address and Unit Identifier |

| Real-time Support | Yes, with scheduled and prioritized messaging | Limited real-time capability |

| Standardization | ODVA Standard | Open Modbus Organization |

| Typical Use Cases | Complex automation networks, industrial control systems | Simple device communication, SCADA systems |

| Security | Basic security, improving with CIP Security | Minimal built-in security |

Introduction to Ethernet/IP and Modbus TCP

Ethernet/IP and Modbus TCP are popular industrial communication protocols designed for seamless data exchange in automation systems. Ethernet/IP utilizes the Common Industrial Protocol (CIP) over standard Ethernet to support real-time control and information sharing, while Modbus TCP operates on the TCP/IP network layer, providing simple and reliable device communication. Your choice between these protocols depends on the complexity of your network and the specific requirements of your industrial applications.

Overview of Industrial Communication Protocols

Ethernet/IP and Modbus TCP are leading industrial communication protocols designed to enhance data exchange in automation systems. Ethernet/IP leverages the Common Industrial Protocol (CIP) for real-time control and information sharing across complex networks, widely used in manufacturing for its scalability and interoperability. Modbus TCP offers a simpler, cost-effective solution for device-to-device communication over Ethernet, favored for its ease of integration in process control and monitoring applications, ensuring your industrial network achieves efficient and reliable connectivity.

Technical Architecture: Ethernet/IP vs Modbus TCP

Ethernet/IP utilizes the Common Industrial Protocol (CIP) over standard Ethernet, supporting both explicit and implicit messaging for real-time control and seamless device integration. Modbus TCP operates on a simpler client-server model using TCP/IP, primarily designed for straightforward device communication without built-in real-time capabilities. Your choice between these protocols depends on the complexity and timing requirements of your industrial networking environment.

Protocol Performance and Speed Comparison

Ethernet/IP offers higher data transfer rates and lower latency compared to Modbus TCP, making it suitable for complex industrial automation systems requiring real-time communication. Modbus TCP, while simpler and easier to implement, typically operates at slower speeds with greater latency, which can impact performance in time-sensitive applications. Your choice between these protocols should consider the required communication speed and the complexity of your network infrastructure.

Data Handling and Scalability

Ethernet/IP offers advanced data handling capabilities with efficient real-time communication and embedded device profiles, making it ideal for complex industrial automation systems requiring high scalability. Modbus TCP, while simpler and widely supported, handles data in a master-slave format that limits its scalability for larger or more dynamic networks. Your choice between Ethernet/IP and Modbus TCP depends on the need for robust data exchange and scalable network expansion in your automation infrastructure.

Integration and Compatibility with Industrial Devices

Ethernet/IP offers extensive integration and compatibility with a wide range of industrial devices from major manufacturers such as Rockwell Automation and Cisco, leveraging the Common Industrial Protocol (CIP) for seamless interoperability. Modbus TCP, based on the widely adopted Modbus protocol, provides straightforward integration with numerous legacy and modern devices, especially in process industries and HVAC systems. Both protocols support Ethernet networking, but Ethernet/IP excels in complex automation environments due to its richer object-oriented data model and standardized device profiles.

Security Features and Vulnerabilities

Ethernet/IP incorporates built-in security features such as device authentication and encryption protocols to safeguard industrial networks, whereas Modbus TCP lacks native encryption and authentication, making it more vulnerable to cyberattacks like man-in-the-middle and replay attacks. Despite Ethernet/IP's enhanced security, both protocols require supplementary measures like firewalls and intrusion detection systems to fully protect your control systems. Understanding these differences helps you select the right protocol based on your network's security requirements and risk profile.

Cost Implications and Infrastructure Requirements

Ethernet/IP typically involves higher initial costs due to licensing fees and more complex infrastructure needs, including managed switches and specialized network components. Modbus TCP offers a cost-effective solution with simpler infrastructure requirements, leveraging standard Ethernet hardware and open protocol advantages, which reduces your overall expenses in installation and maintenance. Choosing between the two depends on balancing your budget constraints with the desired network performance and scalability.

Use Cases and Industry Applications

Ethernet/IP is widely adopted in manufacturing automation, enabling precise control of assembly lines and robotics within automotive and food processing industries. Modbus TCP excels in industrial environments requiring simple, reliable data exchange, such as water treatment plants, energy management, and building automation systems. Your choice depends on the complexity of communication needs, with Ethernet/IP favored for high-speed, device-level control and Modbus TCP suited for basic sensor and actuator data transmission.

Choosing the Right Protocol for Your Automation Needs

Ethernet/IP offers robust real-time communication and extensive device interoperability, making it ideal for complex industrial automation systems requiring high-speed data exchange and scalability. Modbus TCP provides simplicity and wide compatibility with legacy devices, suited for straightforward applications where ease of integration and cost-effectiveness are priorities. Selecting between Ethernet/IP and Modbus TCP depends on factors like network complexity, device diversity, and performance requirements in your automation environment.

Ethernet/IP vs Modbus TCP Infographic

libmatt.com

libmatt.com