Push-pull sensors provide flexibility by allowing the output to either source or sink current, making them compatible with various control inputs, while PNP sensors source current by supplying positive voltage to the load. Choosing between them depends on your system requirements and the type of input your controller accepts.

Table of Comparison

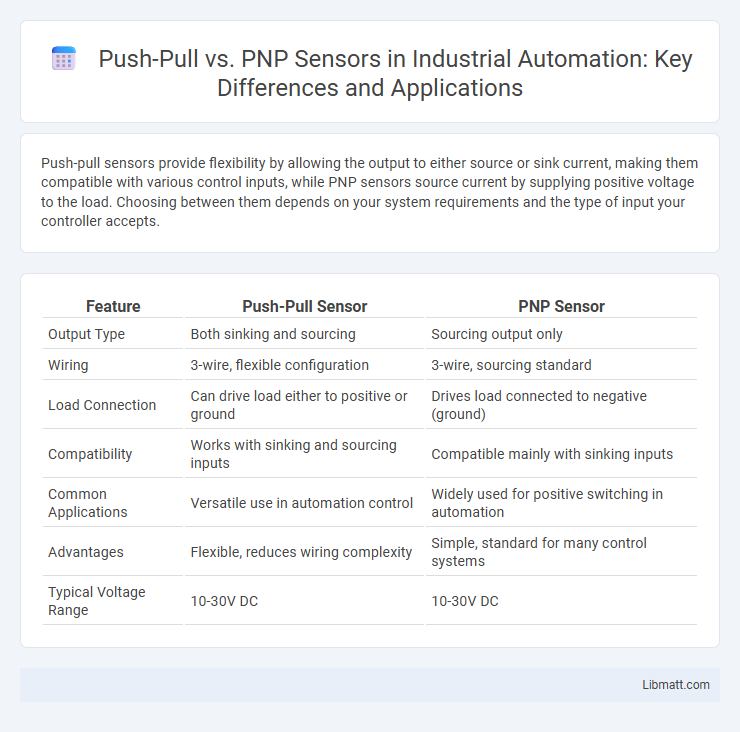

| Feature | Push-Pull Sensor | PNP Sensor |

|---|---|---|

| Output Type | Both sinking and sourcing | Sourcing output only |

| Wiring | 3-wire, flexible configuration | 3-wire, sourcing standard |

| Load Connection | Can drive load either to positive or ground | Drives load connected to negative (ground) |

| Compatibility | Works with sinking and sourcing inputs | Compatible mainly with sinking inputs |

| Common Applications | Versatile use in automation control | Widely used for positive switching in automation |

| Advantages | Flexible, reduces wiring complexity | Simple, standard for many control systems |

| Typical Voltage Range | 10-30V DC | 10-30V DC |

Introduction to Sensor Output Types

Push-pull and PNP sensors differ primarily in their output configurations, which are essential for interfacing with control systems. Push-pull sensors can both source and sink current, providing flexibility in wiring and compatibility across various devices. Your choice between these sensor output types depends on the specific requirements of your application's voltage and current control.

Overview of Push-Pull Sensors

Push-pull sensors feature output transistors that can both source and sink current, enabling flexible interfacing with various loads. This type of sensor provides a reliable switching mechanism with faster response times and reduced wiring complexity compared to traditional PNP sensors. Your applications benefit from enhanced compatibility in diverse automation and control systems using push-pull sensor technology.

Understanding PNP Sensors

PNP sensors operate by sourcing current to the load when activated, making them compatible with positive voltage systems and widely used in industrial automation. Understanding PNP sensors involves recognizing their output configuration where the sensor switches the positive supply voltage to the load, ensuring faster response times and reliable signal transmission. These sensors offer advantages in environments requiring high noise immunity and straightforward wiring with PLCs or control circuits designed for sourcing inputs.

Internal Circuit Differences

Push-Pull sensors feature an internal transistor circuit that can both source and sink current, allowing them to provide either a positive or negative output voltage. PNP sensors contain an internal transistor configured to source current, supplying positive voltage to the load. The key internal circuit difference is that Push-Pull designs integrate both NPN and PNP transistor elements within a single sensor, enabling versatile switching, while PNP sensors solely use a transistor that sources current to the output.

Wiring and Connectivity Comparison

Push-Pull sensors offer versatile wiring options by allowing current to either flow into or out of the load, supporting both sourcing and sinking configurations. PNP sensors operate with sourcing output, providing a positive voltage to the load, which simplifies connectivity in circuits designed for positive switching. Choosing between Push-Pull and PNP sensors depends on the specific wiring requirements and the type of input device to ensure compatibility and optimal signal integrity.

Signal Compatibility with PLCs

Push-pull sensors offer versatile signal compatibility with PLCs by supporting both sourcing and sinking outputs, enabling seamless integration with a wide range of input configurations. PNP sensors provide sourcing signals that supply positive voltage to the PLC input, commonly compatible with most PLCs that accept sourcing inputs. Understanding your specific PLC input type ensures optimal compatibility and reliable sensor communication for your automation system.

Pros and Cons of Push-Pull Sensors

Push-pull sensors offer versatility by allowing output to both source and sink current, enabling compatibility with a wider range of devices and reducing wiring errors. They provide better noise immunity and reliable signal transmission in industrial automation, but tend to be more complex and costly than PNP sensors. However, their dual output capability can increase design flexibility despite slightly higher power consumption.

Advantages and Limitations of PNP Sensors

PNP sensors offer advantages such as easy integration with positive voltage loads and reduced susceptibility to electrical noise, making them ideal for industrial automation applications. Their sourcing output provides a stable voltage signal that simplifies wiring and improves system reliability. However, PNP sensors can face limitations when interfacing with devices requiring sinking inputs, and their compatibility with certain control systems may require additional components or adjustments to ensure proper operation for your setup.

Application Scenarios and Use Cases

Push-Pull sensors, capable of sourcing and sinking current, are ideal for versatile industrial automation applications requiring bidirectional control, such as conveyor systems and robotic arms. PNP sensors, which source current by providing positive voltage, excel in environments with positive common wiring conventions and are commonly used in proximity detection for packaging and material handling. Your choice depends on the specific wiring configuration and control logic of your equipment to ensure compatibility and optimal performance.

Selecting the Right Sensor for Your Needs

Choosing between Push-Pull and PNP sensors depends on the specific application requirements, including load type and wiring configuration. Push-Pull sensors offer versatile output options by sourcing and sinking current, making them ideal for complex control systems. PNP sensors, which source current, are widely preferred for their simplicity and compatibility with most PLC inputs in standard industrial automation environments.

Push-Pull vs PNP Sensor Infographic

libmatt.com

libmatt.com