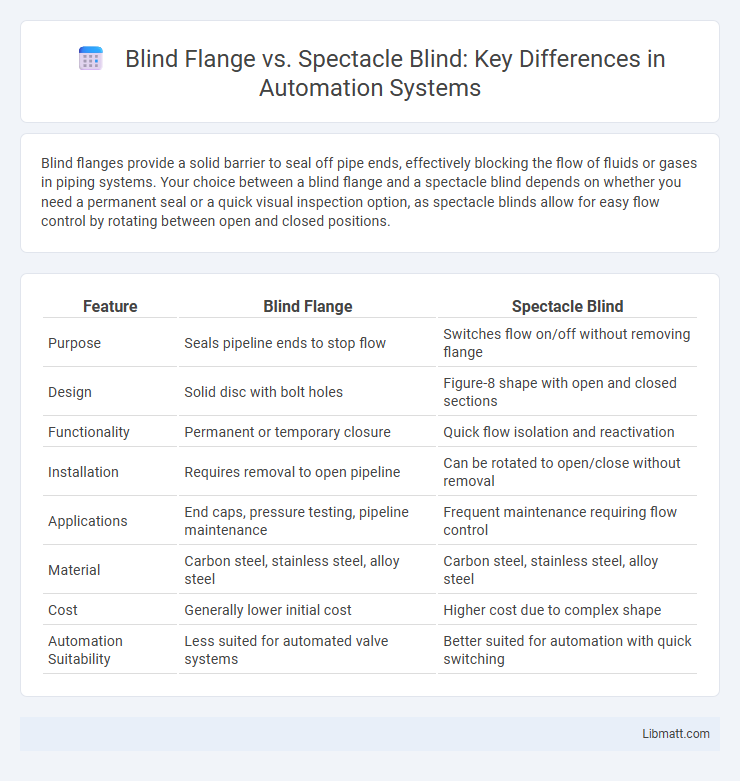

Blind flanges provide a solid barrier to seal off pipe ends, effectively blocking the flow of fluids or gases in piping systems. Your choice between a blind flange and a spectacle blind depends on whether you need a permanent seal or a quick visual inspection option, as spectacle blinds allow for easy flow control by rotating between open and closed positions.

Table of Comparison

| Feature | Blind Flange | Spectacle Blind |

|---|---|---|

| Purpose | Seals pipeline ends to stop flow | Switches flow on/off without removing flange |

| Design | Solid disc with bolt holes | Figure-8 shape with open and closed sections |

| Functionality | Permanent or temporary closure | Quick flow isolation and reactivation |

| Installation | Requires removal to open pipeline | Can be rotated to open/close without removal |

| Applications | End caps, pressure testing, pipeline maintenance | Frequent maintenance requiring flow control |

| Material | Carbon steel, stainless steel, alloy steel | Carbon steel, stainless steel, alloy steel |

| Cost | Generally lower initial cost | Higher cost due to complex shape |

| Automation Suitability | Less suited for automated valve systems | Better suited for automation with quick switching |

Overview of Blind Flange and Spectacle Blind

Blind flanges are solid disks used to seal the ends of pipes or nozzles, providing a secure closure without flow passage, commonly made from materials such as stainless steel or carbon steel. Spectacle blinds consist of a figure-eight-shaped metal plate with one solid disk and one open ring, allowing easy switching between flow-blocking and flow-permitting positions without removing the plate. Both components enhance pipeline safety and maintenance by isolating sections, but spectacle blinds offer more operational flexibility compared to the permanent sealing of blind flanges.

Key Definitions: Blind Flange vs Spectacle Blind

Blind flanges are solid disks used to seal the end of a pipe or valve, preventing flow and providing easy access for inspection or maintenance. Spectacle blinds consist of a pair of interconnected discs, one solid and one open, designed to alternate between allowing flow or isolating sections of a pipeline without removing the blind entirely. Both components are critical in pipeline maintenance, with blind flanges offering a permanent seal and spectacle blinds providing a quick visual indication of pipeline status.

Primary Functions and Applications

Blind flanges provide a secure seal to close the end of a pipe, effectively blocking flow and pressure in pipeline systems. Spectacle blinds consist of a solid plate and an open ring connected by a hinge, allowing operators to quickly switch between blocking and allowing flow for maintenance purposes. Your choice depends on whether you need a permanent seal with blind flanges or a versatile solution for frequent isolation using spectacle blinds.

Material Selection and Durability

Blind flanges and spectacle blinds differ significantly in material selection and durability; blind flanges are typically made from stainless steel, carbon steel, or alloy steel for high strength and corrosion resistance, ideal for sealing pipe ends under high pressure. Spectacle blinds often incorporate similar materials but are designed for easy visual inspection and quick isolation of pipeline sections, emphasizing durability under frequent operations. Your choice should consider the specific operational environment and pressure requirements to ensure optimal performance and longevity.

Installation Procedures and Requirements

Blind flanges require precise alignment and bolting to maintain a tight seal, often necessitating skilled labor and proper gasket installation to prevent leaks. Spectacle blinds involve simpler installation, sliding between flanges with minimal disassembly, making them preferable for quick isolation in maintenance workflows. Your choice depends on the operational complexity and the frequency of line isolation needed.

Pressure Ratings and Performance Differences

Blind flanges and spectacle blinds are designed for pressure containment but differ in performance under varying ratings. Blind flanges typically handle higher pressure ratings, often up to ANSI Class 2500 or higher, providing a robust seal for pipeline isolation. Spectacle blinds are better suited for lower to medium pressure applications and offer a quick visual indication of open or closed pipeline status, enhancing operational safety but with limited pressure endurance compared to blind flanges.

Maintenance and Inspection Considerations

Blind flanges require routine visual inspections for corrosion, gasket integrity, and bolt tightness to ensure a secure seal, with maintenance typically involving bolt replacement and gasket gasket renewal. Spectacle blinds provide a clear visual indicator of open or closed pipeline status, simplifying maintenance by minimizing the risk of operational errors; inspection focuses on hinge condition, locking mechanisms, and flange faces. Both components demand adherence to industry standards such as ASME B16.5 for pressure ratings and dimensional accuracy during inspection and maintenance procedures.

Safety Aspects in Pipeline Operations

Blind flanges and spectacle blinds both serve as essential safety devices in pipeline operations by providing secure isolation during maintenance or system shutdowns, minimizing risk of leaks or accidental flow. Blind flanges offer a solid barrier that withstands high pressure and temperature, ensuring reliable sealing for critical pipeline sections. Spectacle blinds enhance operational safety by allowing quick visual confirmation of open or closed status, reducing human error and improving maintenance efficiency.

Cost Implications and Budget Considerations

Blind flanges typically incur lower initial costs due to simpler design and easier manufacturing processes compared to spectacle blinds, which involve two connected plates and additional pivot points. Spectacle blinds may increase long-term expenses because of maintenance requirements and operational complexity, but they provide enhanced safety and quick isolation capabilities. Your choice should balance upfront budget constraints with anticipated operational efficiency and maintenance costs for optimal cost management.

Choosing the Right Component for Your System

Selecting the right component between blind flanges and spectacle blinds depends on the system's operational needs and maintenance schedules. Blind flanges provide a permanent seal for piping systems, ideal for isolating equipment during routine maintenance or inspection. Spectacle blinds offer a safer, quick-change solution with a visible indicator of flow status, enhancing operational safety and efficiency in systems requiring frequent isolation.

Blind Flange vs Spectacle Blind Infographic

libmatt.com

libmatt.com