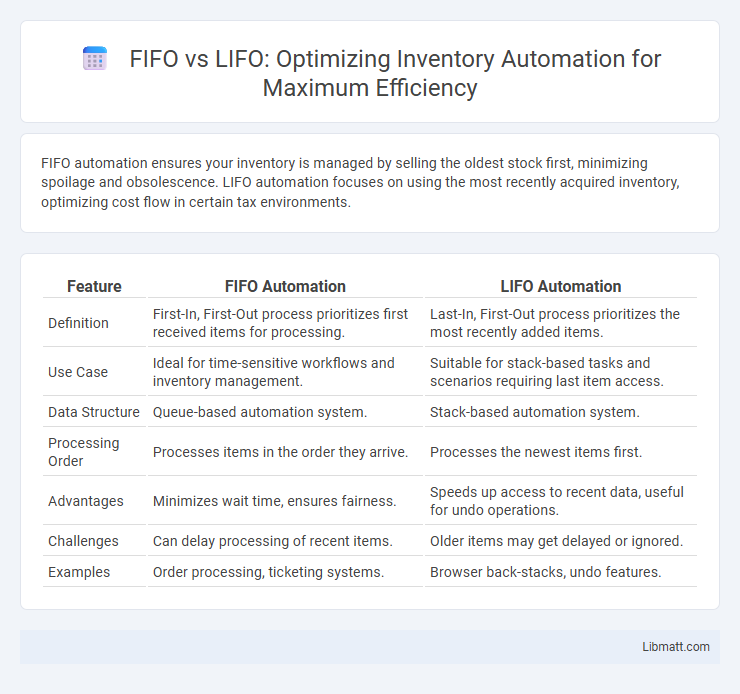

FIFO automation ensures your inventory is managed by selling the oldest stock first, minimizing spoilage and obsolescence. LIFO automation focuses on using the most recently acquired inventory, optimizing cost flow in certain tax environments.

Table of Comparison

| Feature | FIFO Automation | LIFO Automation |

|---|---|---|

| Definition | First-In, First-Out process prioritizes first received items for processing. | Last-In, First-Out process prioritizes the most recently added items. |

| Use Case | Ideal for time-sensitive workflows and inventory management. | Suitable for stack-based tasks and scenarios requiring last item access. |

| Data Structure | Queue-based automation system. | Stack-based automation system. |

| Processing Order | Processes items in the order they arrive. | Processes the newest items first. |

| Advantages | Minimizes wait time, ensures fairness. | Speeds up access to recent data, useful for undo operations. |

| Challenges | Can delay processing of recent items. | Older items may get delayed or ignored. |

| Examples | Order processing, ticketing systems. | Browser back-stacks, undo features. |

Introduction to FIFO and LIFO Automation

FIFO automation ensures inventory is managed by processing the oldest stock first, improving freshness and reducing waste in industries like food and pharmaceuticals. LIFO automation prioritizes the newest inventory, benefiting businesses that deal with non-perishable goods or require tax advantages during inflationary periods. Your choice between FIFO and LIFO automation impacts operational efficiency and financial reporting accuracy.

Defining FIFO and LIFO in Automated Systems

FIFO (First-In, First-Out) automation prioritizes processing or moving items in the order they were received, ensuring older inventory is used before newer stock. LIFO (Last-In, First-Out) automation operates by handling the most recently added items first, often used for inventory that doesn't require chronological rotation. Your choice between FIFO and LIFO automation impacts inventory accuracy, waste reduction, and operational efficiency in automated systems.

Key Differences Between FIFO and LIFO Automation

FIFO automation prioritizes processing items in the exact order they arrive, ensuring older inventory is used first, which reduces spoilage and maintains product freshness. LIFO automation handles the most recent items first, optimizing for scenarios where newer stock is more relevant or valuable, often seen in industries with fluctuating material costs. Your choice between FIFO and LIFO automation impacts inventory accuracy, warehouse efficiency, and compliance with accounting standards.

Advantages of FIFO Automation

FIFO automation ensures inventory management with enhanced accuracy by systematically processing older stock first, reducing product obsolescence and spoilage. It streamlines warehouse operations, improving order fulfillment speed and maintaining fresher inventory for perishable goods. This method supports regulatory compliance for industries like food and pharmaceuticals by maintaining traceability and consistent product rotation.

Benefits of LIFO Automation

LIFO automation enhances inventory management by optimizing stock turnover, reducing holding costs, and improving cash flow through the prioritization of the most recent inventory items for use or sale. This automation method aligns well with fluctuating market prices, allowing for more accurate matching of current costs with revenues, which can lead to tax advantages during inflationary periods. The integration of LIFO automation systems boosts operational efficiency by minimizing manual errors and enabling real-time inventory tracking.

Best Use Cases for FIFO Automation

FIFO automation excels in industries with perishable goods, such as food and pharmaceuticals, where inventory turnover and freshness are critical. It optimizes stock management by ensuring older items are dispatched first, reducing waste and minimizing expiration risks. Retailers and manufacturers benefit from FIFO systems to maintain product quality and comply with safety regulations.

Ideal Applications for LIFO Automation

LIFO automation is ideal for industries dealing with perishable goods or materials with a short shelf life, such as food processing and pharmaceuticals, where the most recently produced items must be used first. This method optimizes inventory turnover and reduces waste by ensuring that newer stock is prioritized, preventing obsolete or expired products. LIFO automation also benefits manufacturing environments managing fluctuating raw material costs, allowing better alignment with current market prices.

Challenges in Implementing FIFO and LIFO Automation

Implementing FIFO and LIFO automation presents challenges such as accurately tracking inventory movement and ensuring system synchronization with physical stock flows. FIFO automation requires precise timestamping and real-time data integration to maintain product freshness and reduce waste, while LIFO automation demands rigorous control over batch tracking to prevent stock discrepancies. Your inventory management system must handle these complexities efficiently to avoid costly errors and maintain operational integrity.

Choosing the Right Automation Approach: FIFO vs LIFO

Choosing between FIFO (First In, First Out) and LIFO (Last In, First Out) automation depends on inventory management goals and product shelf-life. FIFO automation ensures older stock is used first, reducing spoilage and ideal for perishable goods or regulated industries. LIFO automation benefits businesses seeking cost advantages in rising price environments by prioritizing recent inventory usage.

Future Trends in FIFO and LIFO Automation Systems

Future trends in FIFO and LIFO automation systems emphasize integration of AI-powered inventory management and real-time data analytics to optimize stock rotation and reduce waste. Enhanced robotics and IoT connectivity enable seamless adjustment between FIFO and LIFO methods based on demand patterns and product shelf life, increasing operational efficiency. You can expect cloud-based platforms to facilitate scalable, adaptive automation that supports dynamic supply chain strategies and regulatory compliance.

FIFO vs LIFO Automation Infographic

libmatt.com

libmatt.com