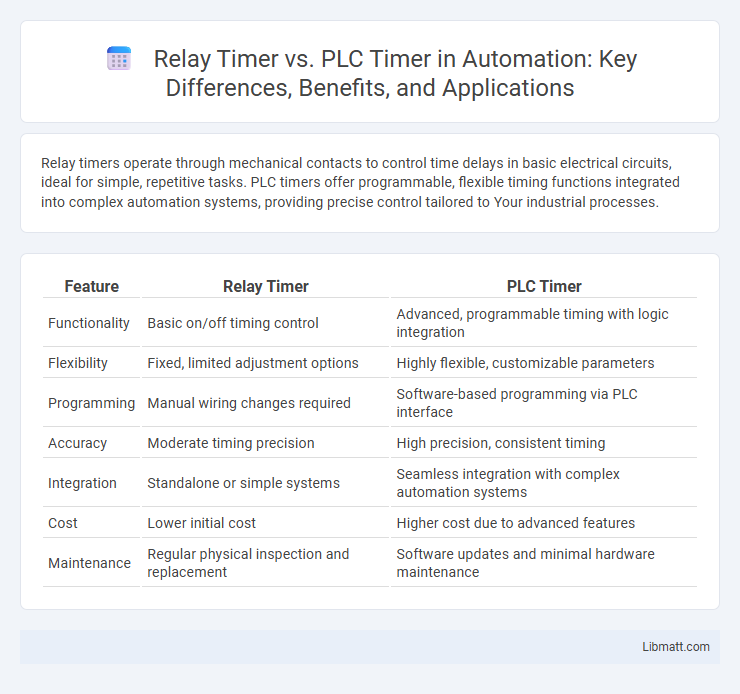

Relay timers operate through mechanical contacts to control time delays in basic electrical circuits, ideal for simple, repetitive tasks. PLC timers offer programmable, flexible timing functions integrated into complex automation systems, providing precise control tailored to Your industrial processes.

Table of Comparison

| Feature | Relay Timer | PLC Timer |

|---|---|---|

| Functionality | Basic on/off timing control | Advanced, programmable timing with logic integration |

| Flexibility | Fixed, limited adjustment options | Highly flexible, customizable parameters |

| Programming | Manual wiring changes required | Software-based programming via PLC interface |

| Accuracy | Moderate timing precision | High precision, consistent timing |

| Integration | Standalone or simple systems | Seamless integration with complex automation systems |

| Cost | Lower initial cost | Higher cost due to advanced features |

| Maintenance | Regular physical inspection and replacement | Software updates and minimal hardware maintenance |

Introduction to Timer Technologies

Relay timers operate using electromechanical components to control time-based functions, providing reliable but limited precision typically suited for simple on/off applications. PLC timers, integrated within programmable logic controllers, offer advanced programmable timing capabilities with high accuracy and flexibility for complex automation processes. Understanding these timer technologies highlights the shift from basic relay-based control to sophisticated digital timing solutions in industrial automation.

What is a Relay Timer?

A Relay Timer is an electromechanical device that controls the timing of electrical circuits by opening or closing contacts after a preset delay. It is commonly used for simple time-delay functions in industrial automation and lighting control systems. Your choice between a Relay Timer and a PLC Timer depends on the complexity and precision required for the timing application.

What is a PLC Timer?

A PLC timer is an integral function within programmable logic controllers used to control the timing of operations in automated systems with high precision and flexibility. Unlike relay timers that operate mechanically and are limited to simple delay functions, PLC timers offer multiple modes such as on-delay, off-delay, and retentive timing, which can be easily programmed and adjusted via software. These timers enhance automation efficiency by enabling complex timing sequences, real-time monitoring, and integration with other PLC-controlled processes.

Core Functional Differences

Relay timers operate through electromechanical contacts to control timing sequences, making them suitable for simple, low-speed timing applications. PLC timers are integrated within programmable logic controllers, offering precise digital timing control and complex, customizable timing functions for industrial automation. The core functional difference lies in relay timers' mechanical switching versus PLC timers' software-based timing logic.

Accuracy and Reliability Comparison

Relay timers operate with mechanical components, leading to lower accuracy and slower response times compared to PLC timers, which use digital processing for precise and repeatable timing control. PLC timers provide higher reliability due to their solid-state design, minimizing wear and tear issues common in relay-based systems. Your automation projects benefit from PLC timers through enhanced timing accuracy and reduced maintenance requirements.

Flexibility and Programming Capabilities

Relay timers operate on fixed mechanical or electronic timing circuits with limited flexibility, making them suitable for simple, repetitive tasks. PLC timers offer extensive programming capabilities, allowing precise time control, customization, and integration within complex automation systems. The adaptability of PLC timers supports advanced functions such as conditional timing, multiple timer modes, and real-time adjustments, enhancing overall process efficiency.

Application Scenarios for Each Timer

Relay timers are ideal for simple, low-cost timing tasks in basic machinery and household appliances where limited programming and flexibility are required. PLC timers excel in complex industrial automation, allowing precise control, integration with multiple sensors, and customizable timing sequences essential for manufacturing and process control. You should choose relay timers for straightforward applications and PLC timers when advanced automation and scalability are needed.

Cost and Maintenance Considerations

Relay timers generally have lower initial costs compared to PLC timers, making them suitable for simple timing applications with limited budgets. Maintenance of relay timers involves regular mechanical inspection and potential replacement due to wear and tear, which can increase long-term expenses. PLC timers, while more expensive upfront, reduce maintenance needs through solid-state components and programmable flexibility, offering better cost efficiency for complex or scalable automation systems.

Integration with Automation Systems

Relay timers offer simple timing control but lack seamless integration with modern automation systems, limiting their use in complex processes. PLC timers provide advanced programmability and communication capabilities, allowing easy integration with various automation protocols such as Modbus, Ethernet/IP, and Profibus. This integration facilitates real-time monitoring, precise timing adjustments, and enhanced system coordination in industrial environments.

Choosing the Right Timer for Your Needs

Selecting between a relay timer and a PLC timer depends on the complexity and precision required in your control system. Relay timers offer simplicity and cost-effectiveness for basic timing tasks, while PLC timers provide advanced programmability, greater accuracy, and integration with complex automation processes. Evaluating factors such as application requirements, scalability, and maintenance demands ensures the optimal timer choice for efficient and reliable operations.

Relay Timer vs PLC Timer Infographic

libmatt.com

libmatt.com