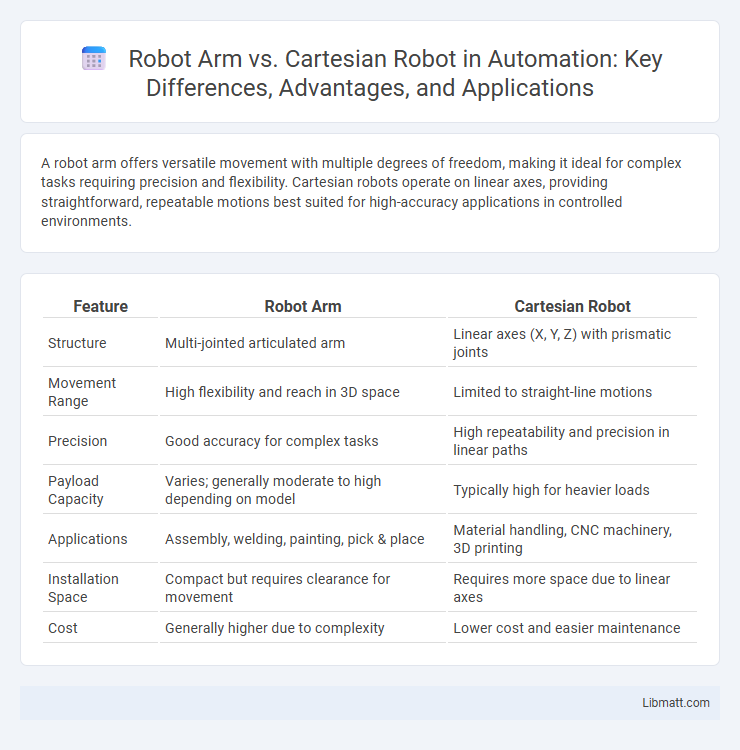

A robot arm offers versatile movement with multiple degrees of freedom, making it ideal for complex tasks requiring precision and flexibility. Cartesian robots operate on linear axes, providing straightforward, repeatable motions best suited for high-accuracy applications in controlled environments.

Table of Comparison

| Feature | Robot Arm | Cartesian Robot |

|---|---|---|

| Structure | Multi-jointed articulated arm | Linear axes (X, Y, Z) with prismatic joints |

| Movement Range | High flexibility and reach in 3D space | Limited to straight-line motions |

| Precision | Good accuracy for complex tasks | High repeatability and precision in linear paths |

| Payload Capacity | Varies; generally moderate to high depending on model | Typically high for heavier loads |

| Applications | Assembly, welding, painting, pick & place | Material handling, CNC machinery, 3D printing |

| Installation Space | Compact but requires clearance for movement | Requires more space due to linear axes |

| Cost | Generally higher due to complexity | Lower cost and easier maintenance |

Introduction to Robot Arms and Cartesian Robots

Robot arms, typically characterized by their articulated joints and rotational movements, offer high flexibility and dexterity for complex tasks such as assembly and welding. Cartesian robots operate along linear axes (X, Y, Z), providing precise, repeatable motion ideal for pick-and-place operations and CNC machining. The choice between robot arms and Cartesian robots depends on application requirements, workspace constraints, and precision needs.

Key Differences Between Robot Arms and Cartesian Robots

Robot arms offer versatile, multi-axis movement suited for complex tasks, while Cartesian robots operate on linear XYZ axes for precise, repeatable motion in simple applications. Robot arms feature articulated joints enabling extensive reach and dexterity, contrasted with the rigid, rectangular coordinate system of Cartesian robots. Your choice depends on the complexity and flexibility required in automation, with robot arms excelling in adaptability and Cartesian systems prioritizing straightforward, high-accuracy positioning.

Design and Structure Comparison

Robot arms feature articulated joints resembling a human arm, providing high flexibility and a wide range of motion ideal for complex tasks. Cartesian robots utilize linear actuators along X, Y, and Z axes, resulting in a rigid, box-shaped structure that excels in precision and repeatability for straightforward movements. The design of robot arms caters to intricate, multi-directional operations, while Cartesian robots prioritize simplicity and stability for tasks requiring linear motion.

Degrees of Freedom: What Sets Them Apart

Robot arms typically offer 5 to 7 degrees of freedom, enabling complex, multi-axis movements critical for tasks like welding, assembly, and painting. Cartesian robots, restricted to 3 degrees of freedom along linear X, Y, and Z axes, excel in precision and repeatability for applications such as pick-and-place operations and CNC machining. The increased degrees of freedom in robot arms allow greater flexibility and reach, while Cartesian robots provide straightforward motion control and easier programming.

Applications in Industry

Robot arms excel in complex assembly tasks, welding, and material handling across automotive and electronics industries due to their multi-axis flexibility and precision. Cartesian robots find extensive use in pick-and-place operations, CNC machining, and 3D printing, benefiting from their straightforward linear motion along defined X, Y, and Z axes. Industrial environments prioritize robot arms for adaptable, intricate workflows, while Cartesian robots dominate tasks requiring high repeatability and simpler movement patterns.

Performance: Speed, Precision, and Versatility

Robot arms excel in versatility, offering multi-axis movement that enables complex tasks with high precision, often achieving repeatability within +-0.01 mm. Cartesian robots deliver superior speed and accuracy along linear paths, making them ideal for applications requiring straightforward, high-speed positioning with repeatability around +-0.02 mm. Your choice depends on whether you need the flexible, intricate manipulation capabilities of a robot arm or the fast, precise linear movements provided by Cartesian robots.

Cost Analysis: Investment and Maintenance

Robot arms typically involve higher initial investment costs due to their complex design and advanced degrees of freedom, making them suitable for versatile applications but budget-sensitive projects may find them expensive. Cartesian robots generally have lower upfront costs and simpler maintenance requirements because their linear motion on fixed axes reduces wear and repair complexity. Maintenance expenses for robot arms tend to be higher due to frequent calibration and potential joint replacements, whereas Cartesian robots incur fewer maintenance costs, contributing to overall cost efficiency in repetitive, linear tasks.

Ease of Programming and Integration

Robot arms offer exceptional flexibility and ease of programming due to their articulated joints, allowing complex movements that adapt efficiently to various tasks. Cartesian robots boast straightforward programming and seamless integration into linear paths and repetitive tasks, making them ideal for precision and simplicity. Your choice depends on task complexity, with robot arms better for dynamic environments and Cartesian robots suited for structured, predictable workflows.

Advantages and Disadvantages of Each Type

Robot arms offer exceptional flexibility and a wide range of motion, making them ideal for complex tasks such as welding and assembly, but they can be expensive and require advanced programming. Cartesian robots excel in precision and simplicity, with a straightforward design that minimizes maintenance and is cost-effective, yet their limited range of motion restricts applications to linear movements along fixed axes. You should consider the specific requirements of your task, such as the need for versatility or accuracy, when choosing between a robot arm and a Cartesian robot.

Choosing the Right Robot for Your Application

Choosing the right robot for your application depends on the specific requirements of precision, reach, and flexibility. Robot arms excel in tasks requiring high dexterity, multi-axis movement, and complex assembly, while Cartesian robots offer reliable linear motion with straightforward programming and higher load capacities. Your decision should prioritize factors like workspace size, payload weight, and required repeatability to optimize performance and efficiency.

Robot Arm vs Cartesian Robot Infographic

libmatt.com

libmatt.com