M12 connectors offer robust performance and are typically used in industrial automation where durability and secure connections are critical, while M8 connectors are smaller, making them ideal for space-constrained applications and lighter data transmission needs. Your choice between M12 and M8 connectors should consider the environmental conditions, size limitations, and power or signal requirements of your specific project.

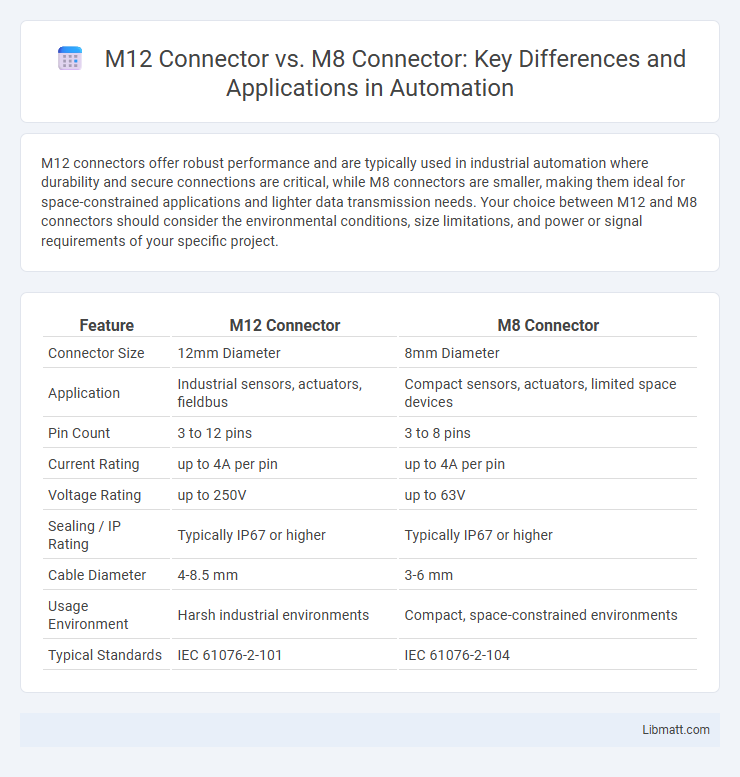

Table of Comparison

| Feature | M12 Connector | M8 Connector |

|---|---|---|

| Connector Size | 12mm Diameter | 8mm Diameter |

| Application | Industrial sensors, actuators, fieldbus | Compact sensors, actuators, limited space devices |

| Pin Count | 3 to 12 pins | 3 to 8 pins |

| Current Rating | up to 4A per pin | up to 4A per pin |

| Voltage Rating | up to 250V | up to 63V |

| Sealing / IP Rating | Typically IP67 or higher | Typically IP67 or higher |

| Cable Diameter | 4-8.5 mm | 3-6 mm |

| Usage Environment | Harsh industrial environments | Compact, space-constrained environments |

| Typical Standards | IEC 61076-2-101 | IEC 61076-2-104 |

Introduction to M12 and M8 Connectors

M12 and M8 connectors are cylindrical connectors widely used in industrial automation for sensor and actuator connections. The M12 connector features a 12mm threaded locking mechanism suitable for complex applications requiring robustness and higher pin counts, while the M8 connector, with an 8mm thread, is compact and ideal for space-constrained environments. Both connectors offer reliable electrical connections with varying sizes influencing their current-carrying capacity and environmental resistance levels.

Key Differences Between M12 and M8 Connectors

M12 connectors feature a 12 mm diameter and are typically used for industrial automation applications requiring higher pin counts and robust data transmission, whereas M8 connectors have an 8 mm diameter, suited for compact sensor connections with fewer pins. M12 connectors support up to 17 pins, offering greater flexibility for complex wiring configurations, while M8 connectors usually provide up to 8 pins, ideal for simpler signal and power needs. Your choice between M12 and M8 connectors depends on space constraints, pin requirements, and environmental durability needed for your application.

Size and Design Comparison

M12 connectors feature a larger 12 mm diameter compared to the compact 8 mm size of M8 connectors, making M12 suitable for applications requiring higher durability and signal integrity. The M12 design incorporates a robust locking mechanism with multiple codings for enhanced versatility, while M8 connectors offer a more streamlined design optimized for limited space in compact devices. Both connectors maintain circular housing but differ in pin configuration density and mechanical strength, with M12 providing greater resistance to harsh industrial environments.

Electrical and Mechanical Specifications

M12 connectors typically support higher current ratings up to 4A and voltages around 250V, while M8 connectors handle currents up to 4A but with lower voltage capacities, usually near 60V. Mechanically, M12 connectors have a 12 mm thread diameter offering robust coupling suited for industrial applications requiring vibration resistance, whereas M8 connectors feature an 8 mm thread diameter, providing a compact and lightweight solution for tight spaces. Your choice depends on the electrical load demands and mechanical durability needed for the specific application environment.

Typical Applications for M12 Connectors

M12 connectors are widely used in industrial automation, sensors, actuators, and robotics due to their robust design and ability to handle higher data transmission rates. Their durability and IP67/IP68 ratings make them ideal for use in harsh environments such as manufacturing floors and outdoor installations. You can rely on M12 connectors for secure and reliable connections in complex machinery and factory automation systems.

Typical Applications for M8 Connectors

M8 connectors are commonly used in sensor and actuator connections within industrial automation, offering compact sizes ideal for limited space environments. Their robust design supports data transmission and power delivery in applications such as factory robotics, conveyor systems, and process control. You can rely on M8 connectors for reliable, efficient interconnections in small-scale industrial and manufacturing equipment.

Environmental Resistance and Durability

M12 connectors offer superior environmental resistance and durability compared to M8 connectors, featuring enhanced sealing ratings such as IP67 and IP68, making them ideal for harsh industrial environments with exposure to water, dust, and vibrations. M8 connectors, while compact and suitable for applications with limited space, typically provide lower ingress protection, around IP65 to IP67, and are best used in less demanding conditions. Your choice between M12 and M8 connectors should consider the required robustness and resistance to environmental factors to ensure reliable long-term performance.

Installation and Maintenance Considerations

M12 connectors require precise alignment during installation due to their smaller size and multiple pin configurations, which can make maintenance more challenging in tight spaces compared to M8 connectors. M8 connectors offer easier installation and quicker maintenance with fewer pins and a more straightforward locking mechanism, suitable for applications where space and time efficiency are crucial. Both connectors demand proper sealing and torque control to ensure durability and prevent environmental ingress, impacting long-term maintenance cycles.

Cost Comparison: M12 vs M8 Connectors

M8 connectors typically offer a lower price point compared to M12 connectors due to their smaller size and simpler design, making them cost-effective for basic sensor and automation applications. M12 connectors, while more expensive, provide enhanced durability, higher pin counts, and better shielding options suited for industrial environments requiring robust performance. Choosing between M8 and M12 connectors depends on balancing budget constraints with the specific technical requirements of the application.

Choosing the Right Connector for Your Application

Selecting between M12 connectors and M8 connectors depends on application requirements such as size constraints, power needs, and data transmission rates. M12 connectors offer robust performance for industrial automation with higher pin counts and enhanced durability, suitable for sensors, actuators, and Ethernet connections. M8 connectors are more compact, ideal for space-limited installations requiring fewer pins and moderate data transfer, commonly used in sensor devices and control systems.

M12 Connector vs M8 Connector Infographic

libmatt.com

libmatt.com