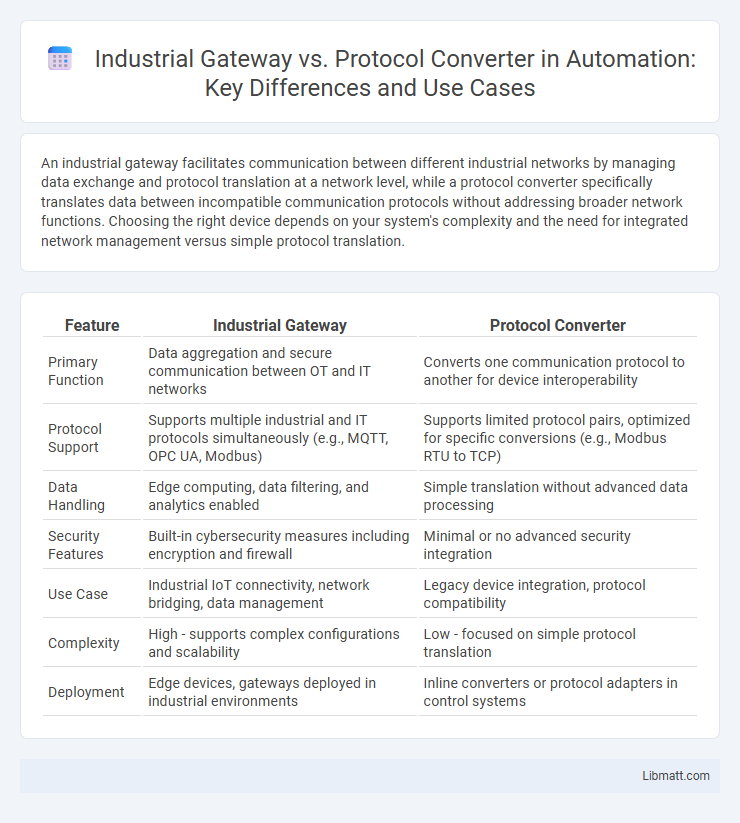

An industrial gateway facilitates communication between different industrial networks by managing data exchange and protocol translation at a network level, while a protocol converter specifically translates data between incompatible communication protocols without addressing broader network functions. Choosing the right device depends on your system's complexity and the need for integrated network management versus simple protocol translation.

Table of Comparison

| Feature | Industrial Gateway | Protocol Converter |

|---|---|---|

| Primary Function | Data aggregation and secure communication between OT and IT networks | Converts one communication protocol to another for device interoperability |

| Protocol Support | Supports multiple industrial and IT protocols simultaneously (e.g., MQTT, OPC UA, Modbus) | Supports limited protocol pairs, optimized for specific conversions (e.g., Modbus RTU to TCP) |

| Data Handling | Edge computing, data filtering, and analytics enabled | Simple translation without advanced data processing |

| Security Features | Built-in cybersecurity measures including encryption and firewall | Minimal or no advanced security integration |

| Use Case | Industrial IoT connectivity, network bridging, data management | Legacy device integration, protocol compatibility |

| Complexity | High - supports complex configurations and scalability | Low - focused on simple protocol translation |

| Deployment | Edge devices, gateways deployed in industrial environments | Inline converters or protocol adapters in control systems |

Introduction to Industrial Gateways and Protocol Converters

Industrial Gateways serve as crucial intermediaries that connect diverse industrial devices and systems, enabling seamless data communication across different network protocols. Protocol Converters specifically translate communication protocols between incompatible industrial equipment, ensuring interoperability within complex automation environments. You can optimize your industrial network's efficiency by selecting the appropriate device to bridge communication gaps and enhance data exchange.

Defining Industrial Gateways

Industrial gateways serve as centralized devices that connect diverse industrial networks and protocols, enabling seamless data exchange between machines, sensors, and control systems. Unlike protocol converters that primarily translate communication protocols, industrial gateways offer advanced functionalities such as data aggregation, filtering, and secure cloud connectivity. These gateways are essential in optimizing industrial IoT implementations by providing interoperability and real-time data flow management across complex automation environments.

What is a Protocol Converter?

A protocol converter is a device that enables communication between different industrial networks by translating protocols used in various automation systems. It ensures seamless data exchange by converting signals and command formats from one protocol to another, supporting diverse equipment interoperability. Your choice between an industrial gateway and a protocol converter depends on whether you need broad network integration or specific protocol translation.

Key Functions of Industrial Gateways

Industrial gateways primarily serve to connect diverse industrial networks, enabling seamless data transfer between different communication protocols such as Modbus, OPC UA, and Ethernet/IP. These devices facilitate real-time monitoring, device management, and remote control, enhancing operational efficiency and data integration for industrial systems. Your industrial gateway simplifies complex interoperability challenges that protocol converters often handle by focusing on network connectivity and protocol translation at a broader scale.

Main Features of Protocol Converters

Protocol converters primarily enable seamless communication between incompatible industrial devices by translating data formats and communication protocols. They support multiple protocols such as Modbus, Profibus, and Ethernet/IP, ensuring interoperability in complex automation systems. Your network benefits from enhanced device integration and streamlined data exchange, improving overall operational efficiency.

Industrial Gateway vs Protocol Converter: Core Differences

Industrial gateways enable seamless communication across multiple industrial networks by supporting various protocols simultaneously, facilitating data exchange in complex automation systems. Protocol converters specifically translate data between two distinct communication protocols, focusing on interoperability between otherwise incompatible devices or systems. The core difference lies in industrial gateways serving as multifunctional communication hubs, while protocol converters act as specialized translators for protocol compatibility.

Use Cases for Industrial Gateways

Industrial gateways serve as critical devices in industrial environments by enabling seamless communication between various network protocols and systems, facilitating data aggregation from sensors, PLCs, and SCADA systems. Use cases for industrial gateways include remote monitoring and control of manufacturing processes, integration of legacy equipment with modern IoT platforms, and secure data transmission across different industrial networks. Your facility benefits from improved operational efficiency and real-time analytics by leveraging industrial gateways to bridge communication gaps in complex automation ecosystems.

Applications of Protocol Converters

Protocol converters enable seamless communication between devices using different industrial protocols, facilitating integration in manufacturing automation, building management systems, and energy distribution networks. They are crucial in legacy system modernization, allowing older equipment to connect with modern networks without hardware replacement. Protocol converters enhance operational efficiency by bridging Modbus, PROFIBUS, DNP3, and other protocols in SCADA systems and IoT deployments.

Factors to Consider When Choosing Between an Industrial Gateway and Protocol Converter

When choosing between an industrial gateway and a protocol converter, consider the complexity of required data processing and the number of supported communication protocols; industrial gateways typically handle multiple protocols and offer higher data processing capabilities. Evaluate network architecture compatibility and scalability needs, as gateways provide advanced routing and integration features, whereas protocol converters mainly focus on bridging specific protocol differences. Assess security requirements and data management functionalities to ensure the selected device supports encryption, authentication, and efficient data flow control within your industrial IoT ecosystem.

Future Trends in Industrial Data Connectivity

Industrial gateways and protocol converters are pivotal in advancing Industrial Internet of Things (IIoT) connectivity by supporting diverse communication protocols and enabling seamless data exchange across legacy and modern systems. Future trends emphasize enhanced edge computing capabilities, AI-driven analytics integration, and increased support for OPC UA and 5G technologies to ensure real-time, secure, and scalable industrial data connectivity. The convergence of these technologies accelerates digital transformation, optimizing operational efficiency and predictive maintenance in manufacturing environments.

Industrial Gateway vs Protocol Converter Infographic

libmatt.com

libmatt.com