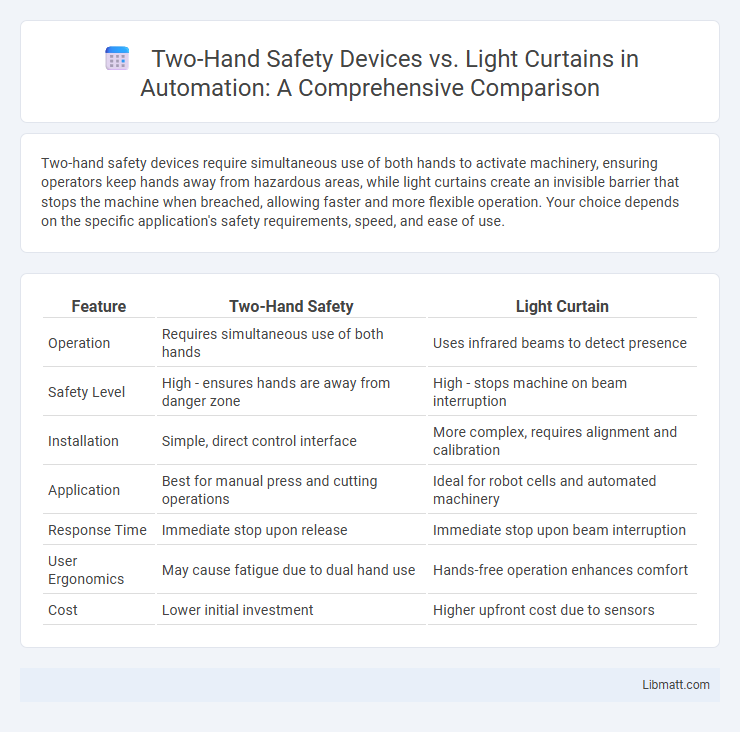

Two-hand safety devices require simultaneous use of both hands to activate machinery, ensuring operators keep hands away from hazardous areas, while light curtains create an invisible barrier that stops the machine when breached, allowing faster and more flexible operation. Your choice depends on the specific application's safety requirements, speed, and ease of use.

Table of Comparison

| Feature | Two-Hand Safety | Light Curtain |

|---|---|---|

| Operation | Requires simultaneous use of both hands | Uses infrared beams to detect presence |

| Safety Level | High - ensures hands are away from danger zone | High - stops machine on beam interruption |

| Installation | Simple, direct control interface | More complex, requires alignment and calibration |

| Application | Best for manual press and cutting operations | Ideal for robot cells and automated machinery |

| Response Time | Immediate stop upon release | Immediate stop upon beam interruption |

| User Ergonomics | May cause fatigue due to dual hand use | Hands-free operation enhances comfort |

| Cost | Lower initial investment | Higher upfront cost due to sensors |

Introduction to Two-Hand Safety and Light Curtains

Two-Hand Safety devices require simultaneous use of both hands to activate machinery, ensuring your hands are kept away from hazardous areas during operation. Light curtains use optical sensors to create an invisible barrier that stops machinery when an object or person interrupts the light beams, providing non-contact protection. Both systems enhance workplace safety by preventing accidents, but your choice depends on the specific operational needs and machine interface.

Understanding Two-Hand Safety Controls

Two-hand safety controls are engineered to require simultaneous activation of two separate buttons, ensuring that both hands are engaged and away from dangerous machine parts during operation. This system reduces the risk of accidental activation while allowing precise control over machinery, making it essential for tasks requiring steady manual input. Understanding your machine's safety features helps you choose between two-hand safety controls and light curtains to optimize workplace protection effectively.

What Are Light Curtains?

Light curtains are optoelectronic safety devices designed to create an invisible barrier using infrared beams to detect the presence of objects or personnel in hazardous areas. Commonly employed in industrial automation and machinery safeguarding, they provide rapid response to interruptions in the light field, preventing accidents by stopping machine operation instantly. Unlike two-hand safety controls, light curtains offer non-contact protection, allowing for greater flexibility and efficiency in high-speed production environments.

Key Differences Between Two-Hand Safety and Light Curtains

Two-hand safety devices require simultaneous manual activation of two separate switches to ensure the operator's hands are safely positioned away from hazardous machinery, providing direct physical control. Light curtains use an array of infrared beams that detect the presence of hands or objects interrupting the light path, offering a non-contact safety solution ideal for faster, high-throughput environments. Your choice depends on the specific application, required speed, and level of protection needed, with two-hand controls emphasizing intentional operator actions and light curtains enabling continuous monitoring.

Safety Standards and Compliance Requirements

Two-hand safety devices and light curtains both comply with strict safety standards such as ISO 13849 and IEC 61508, ensuring reliable risk reduction in industrial environments. Two-hand controls require operators to engage both hands simultaneously, directly meeting compliance for preventing access to hazardous zones under ISO 13851. Light curtains provide continuous presence sensing and meet ANSI B11.19 and OSHA regulations by creating a protective barrier, offering superior compliance for automated machinery with fast response times and selective zone monitoring. Your choice depends on the specific safety performance level (PL) required and the application's operational complexity.

Application Scenarios: When to Use Each Technology

Two-hand safety devices are ideal for applications requiring deliberate manual activation, such as press machines and stamping operations, where both hands must be engaged to prevent accidental injuries. Light curtains excel in environments with frequent material handling or irregular movements, like assembly lines and packaging stations, offering non-contact protection by detecting interruptions in infrared beams. Choosing between the two depends on the specific task dynamics, space constraints, and the need for speed versus absolute hand presence verification.

Advantages of Two-Hand Safety Systems

Two-hand safety systems provide a reliable physical barrier ensuring operators use both hands, reducing the risk of accidental machine activation and enhancing overall workplace safety. These systems are simple to install, require minimal maintenance, and are cost-effective compared to more complex solutions like light curtains. Your manufacturing environment benefits from consistent compliance with safety regulations while maintaining efficient operational workflows.

Benefits of Light Curtain Safety Solutions

Light curtain safety solutions offer non-contact protection that enhances productivity by eliminating the need for physical barriers, allowing your machinery to operate with minimal interruption. These advanced systems provide precise detection of objects or body parts entering hazardous zones, significantly reducing the risk of injury without limiting operator movement. Integrating light curtains ensures compliance with safety standards while maintaining efficient workflow in industrial environments.

Cost Considerations and Maintenance Needs

Two-hand safety devices offer an affordable initial investment with minimal ongoing maintenance, making them ideal for budget-conscious operations. Light curtains involve higher upfront costs due to advanced sensor technology but reduce long-term expenses by minimizing mechanical wear and downtime. Your choice depends on balancing these cost considerations against the specific maintenance capabilities and safety requirements of your workspace.

Choosing the Right Safety Solution for Your Workplace

Two-hand safety devices ensure machine operation only when both hands are engaged, reducing the risk of accidental injury and offering a cost-effective solution for simple applications. Light curtains provide non-contact, flexible protection by detecting hand or finger presence in hazardous zones, ideal for complex or automated environments requiring faster cycle times. Selecting the right safety solution depends on factors like machine type, production speed, operator interaction, and safety standards compliance to balance efficiency and worker protection effectively.

Two-Hand Safety vs Light Curtain Infographic

libmatt.com

libmatt.com