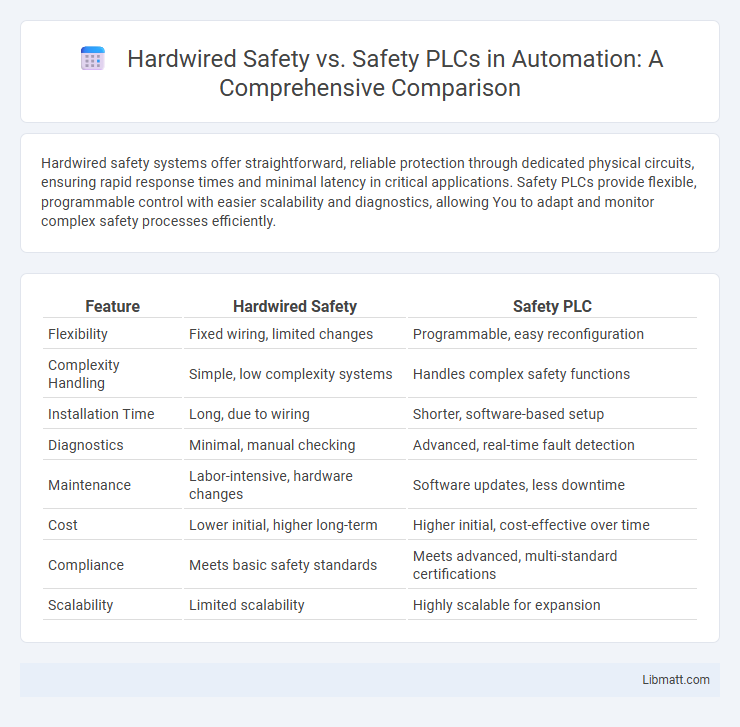

Hardwired safety systems offer straightforward, reliable protection through dedicated physical circuits, ensuring rapid response times and minimal latency in critical applications. Safety PLCs provide flexible, programmable control with easier scalability and diagnostics, allowing You to adapt and monitor complex safety processes efficiently.

Table of Comparison

| Feature | Hardwired Safety | Safety PLC |

|---|---|---|

| Flexibility | Fixed wiring, limited changes | Programmable, easy reconfiguration |

| Complexity Handling | Simple, low complexity systems | Handles complex safety functions |

| Installation Time | Long, due to wiring | Shorter, software-based setup |

| Diagnostics | Minimal, manual checking | Advanced, real-time fault detection |

| Maintenance | Labor-intensive, hardware changes | Software updates, less downtime |

| Cost | Lower initial, higher long-term | Higher initial, cost-effective over time |

| Compliance | Meets basic safety standards | Meets advanced, multi-standard certifications |

| Scalability | Limited scalability | Highly scalable for expansion |

Understanding Hardwired Safety Systems

Hardwired safety systems use discrete components like relays, switches, and sensors to create fail-safe mechanisms that respond directly to specific hazards, ensuring immediate and reliable protection. These systems operate through dedicated wiring and predefined logic, offering simplicity and high integrity without the complexity of software-based control. Understanding their robustness is crucial when selecting safety solutions for environments requiring dependable, deterministic responses.

Introduction to Safety PLCs

Safety PLCs provide flexible, programmable control systems designed to monitor and manage complex safety functions across industrial processes. Unlike hardwired safety systems that rely on fixed wiring and discrete components, Safety PLCs use software logic to detect faults and initiate protective responses efficiently. Your facility benefits from enhanced diagnostics, easier modifications, and scalable safety solutions when implementing a Safety PLC.

Key Components of Hardwired Safety

Hardwired safety systems rely on physical components such as emergency stop buttons, safety relays, safety light curtains, and limit switches to ensure machine safety by directly interrupting power or control signals during hazardous conditions. These components are designed for high reliability and immediate response without the need for software, making them ideal for simple, well-defined safety functions. Understanding these key components helps you determine when a hardwired safety approach is most suitable for your industrial application.

Functionality of Safety PLCs

Safety PLCs offer advanced functionality by integrating complex safety logic, diagnostics, and communication capabilities within a single programmable device. Unlike hardwired safety systems that rely on fixed hardware circuits, Safety PLCs can be easily configured and modified through software, enabling greater flexibility and customization for diverse industrial safety applications. Their ability to monitor multiple safety inputs, execute real-time safety functions, and provide detailed fault diagnostics enhances overall system reliability and reduces downtime.

Reliability Comparison: Hardwired vs. Safety PLC

Hardwired safety systems offer high reliability due to their simple, fixed wiring and minimal software dependency, reducing the risk of programming errors and cyber vulnerabilities. Safety PLCs provide enhanced diagnostic capabilities and flexible configurations, allowing for complex safety functions and real-time monitoring, which improves overall system reliability through early fault detection. The choice between hardwired safety and safety PLCs depends on the specific application demands, with hardwired systems favored for straightforward, high-integrity safety tasks and safety PLCs preferred for scalable, adaptable safety solutions.

Flexibility and Scalability Considerations

Hardwired safety systems offer limited flexibility and scalability due to fixed wiring and predefined logic, making modifications complex and costly. Safety PLCs provide enhanced adaptability with programmable logic that can be easily updated or expanded to accommodate evolving safety requirements and system expansions. This scalability enables quicker integration of new safety functions and improved maintenance efficiency in dynamic industrial environments.

Maintenance and Troubleshooting Differences

Hardwired safety systems require manual inspection and physical testing during maintenance, often leading to longer downtime compared to Safety PLCs, which offer real-time diagnostics and fault detection through integrated software tools. Troubleshooting in hardwired setups involves tracing wiring and components individually, whereas Safety PLCs provide centralized fault codes and status indicators that streamline fault isolation and reduce response time. The use of Safety PLCs enhances maintainability by enabling remote monitoring and predictive maintenance, lowering operational costs and improving system reliability.

Cost Implications of Each System

Hardwired safety systems often entail higher upfront costs due to extensive wiring, installation labor, and physical components, but they benefit from lower maintenance expenses over time. Safety PLCs present higher initial investment for programmable hardware and software licensing, yet offer cost savings through flexibility, easier modifications, and reduced downtime in complex or evolving operations. Your choice should consider both immediate budget and long-term operational cost efficiency based on system complexity and scalability needs.

Application Suitability: Selecting the Right Solution

Hardwired safety systems excel in simple, fixed-function applications requiring rapid response times and straightforward implementation, such as emergency stop circuits and safety interlocks. Safety PLCs (Programmable Logic Controllers) are better suited for complex, modular, and scalable safety functions involving multiple inputs, diagnostics, and integration with other control systems. Choosing between hardwired safety and Safety PLC depends on factors like system complexity, flexibility requirements, maintenance needs, and regulatory compliance.

Future Trends in Industrial Safety Control

Hardwired safety systems rely on fixed wiring and discrete components, offering simplicity and reliability but limited flexibility for complex applications. Safety PLCs provide programmable logic with advanced diagnostics, scalability, and integration capabilities, making them ideal for evolving industrial safety needs. Future trends emphasize increased connectivity, artificial intelligence, and predictive maintenance, enabling Your safety controls to become more adaptive and efficient in dynamic industrial environments.

Hardwired Safety vs Safety PLC Infographic

libmatt.com

libmatt.com