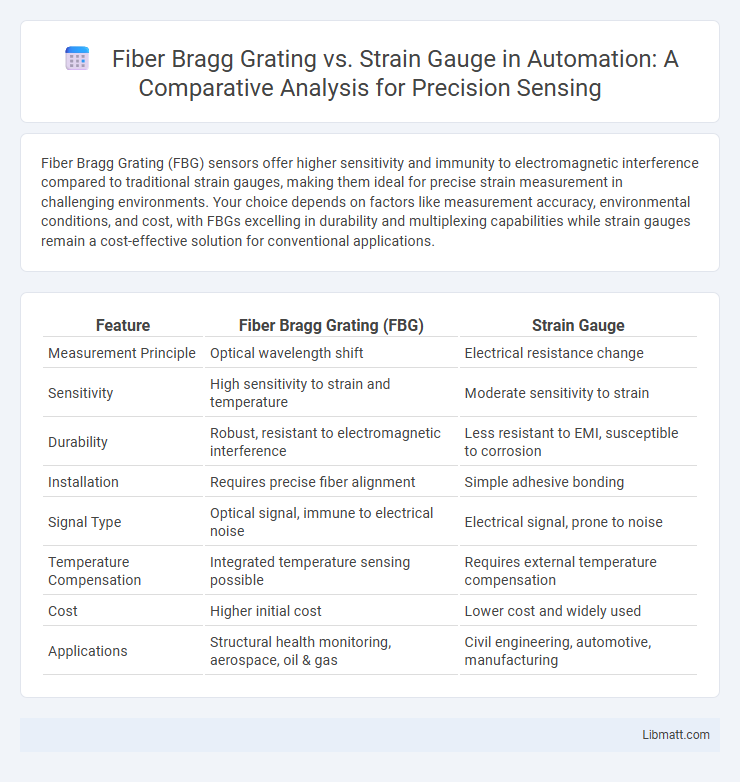

Fiber Bragg Grating (FBG) sensors offer higher sensitivity and immunity to electromagnetic interference compared to traditional strain gauges, making them ideal for precise strain measurement in challenging environments. Your choice depends on factors like measurement accuracy, environmental conditions, and cost, with FBGs excelling in durability and multiplexing capabilities while strain gauges remain a cost-effective solution for conventional applications.

Table of Comparison

| Feature | Fiber Bragg Grating (FBG) | Strain Gauge |

|---|---|---|

| Measurement Principle | Optical wavelength shift | Electrical resistance change |

| Sensitivity | High sensitivity to strain and temperature | Moderate sensitivity to strain |

| Durability | Robust, resistant to electromagnetic interference | Less resistant to EMI, susceptible to corrosion |

| Installation | Requires precise fiber alignment | Simple adhesive bonding |

| Signal Type | Optical signal, immune to electrical noise | Electrical signal, prone to noise |

| Temperature Compensation | Integrated temperature sensing possible | Requires external temperature compensation |

| Cost | Higher initial cost | Lower cost and widely used |

| Applications | Structural health monitoring, aerospace, oil & gas | Civil engineering, automotive, manufacturing |

Introduction to Fiber Bragg Grating and Strain Gauge Technologies

Fiber Bragg Grating (FBG) sensors use periodic variations in the refractive index within an optical fiber to measure strain and temperature with high precision and immunity to electromagnetic interference. Strain gauges rely on the change in electrical resistance of a metal foil or semiconductor material bonded to a surface to quantify deformation. FBG sensors offer advantages in multiplexing capability and durability, while traditional strain gauges remain widely used for their simplicity and cost-effectiveness in various structural health monitoring applications.

Working Principles: Fiber Bragg Grating vs. Strain Gauge

Fiber Bragg Gratings (FBGs) operate by reflecting specific wavelengths of light that shift in response to strain or temperature changes, enabling precise measurement through optical signals. Strain gauges measure strain by changing their electrical resistance when deformed, allowing quantification of mechanical stress via variations in voltage. FBGs offer high sensitivity and immunity to electromagnetic interference, while strain gauges are widely used for their simplicity and cost-effectiveness in direct mechanical strain detection.

Key Advantages of Fiber Bragg Grating Sensors

Fiber Bragg Grating (FBG) sensors offer superior resistance to electromagnetic interference, making them ideal for precise strain measurements in harsh environments. These sensors provide high sensitivity and multiplexing capability, allowing multiple sensing points along a single fiber, which reduces wiring complexity and installation costs compared to traditional strain gauges. The inherent durability and corrosion resistance of FBG sensors result in longer operational lifespan and enhanced reliability in structural health monitoring applications.

Benefits of Traditional Strain Gauges

Traditional strain gauges offer reliable and cost-effective measurement of strain with proven accuracy in various engineering applications. Their simple installation and compatibility with standard data acquisition systems make them accessible for routine structural health monitoring. You benefit from decades of calibrated performance and widespread industry acceptance, ensuring consistent and repeatable results.

Accuracy and Sensitivity Comparison

Fiber Bragg Gratings (FBGs) exhibit higher accuracy and sensitivity than traditional strain gauges due to their ability to detect minute wavelength shifts resulting from strain changes. FBG sensors provide superior immunity to electromagnetic interference, ensuring precise measurements in harsh environments where strain gauges may falter. Strain gauges typically offer sensitivity in the microstrain range, while FBGs can detect nanostrain-level variations, making them ideal for high-precision structural health monitoring.

Environmental Durability and Longevity

Fiber Bragg Gratings (FBGs) exhibit superior environmental durability compared to traditional strain gauges, as they are highly resistant to electromagnetic interference, corrosion, and temperature fluctuations. FBG sensors maintain their accuracy and structural integrity over extended periods in harsh conditions, often exceeding several decades of operational lifespan. In contrast, strain gauges are more susceptible to environmental degradation such as moisture ingress and adhesive failure, which can significantly reduce their longevity and reliability in long-term applications.

Installation Process and Practical Challenges

Fiber Bragg Gratings (FBGs) require precise alignment and bonding to optical fibers, demanding specialized equipment and skilled technicians for installation. Strain gauges involve surface preparation and adhesive application directly onto the structure, which is simpler but susceptible to environmental factors like moisture and temperature fluctuations. Practical challenges for FBGs include sensitivity to microbending and connector losses, while strain gauges face issues such as adhesive degradation and signal drift over time.

Cost-Effectiveness and Scalability

Fiber Bragg Grating (FBG) sensors offer higher cost-effectiveness in large-scale applications due to their multiplexing capability, reducing the need for multiple sensor installations compared to traditional strain gauges. FBG sensors provide scalable solutions with lightweight, durable optical fibers that enable long-distance sensing and lower maintenance costs, making them ideal for extensive structural health monitoring. Your choice impacts long-term investment; while strain gauges are cheaper for small, localized measurements, FBG systems deliver better scalability and overall savings in broader deployments.

Application Scenarios: Industrial and Structural Monitoring

Fiber Bragg Grating (FBG) sensors excel in industrial and structural monitoring with high precision in harsh environments, offering superior resistance to electromagnetic interference and long-term stability compared to traditional strain gauges. Your choice between FBG and strain gauges depends on factors such as measurement range, environmental conditions, and the need for multiplexing multiple sensing points along a single fiber. FBGs are ideal for large-scale structural health monitoring in bridges, pipelines, and aerospace applications, while strain gauges suit simpler, cost-effective strain measurement tasks in controlled settings.

Future Trends and Innovations in Strain Sensing Technologies

Fiber Bragg Grating (FBG) sensors are advancing with enhanced multiplexing capabilities and improved sensitivity, poised to revolutionize structural health monitoring by providing real-time, distributed strain measurements over large areas. Strain gauges, while traditionally valued for their simplicity and affordability, are integrating with wireless and IoT technologies to enable smarter, more accessible data collection. Your choice of strain sensing technology should consider future trends such as miniaturization, increased durability, and seamless integration with digital platforms for predictive maintenance.

Fiber Bragg Grating vs Strain Gauge Infographic

libmatt.com

libmatt.com