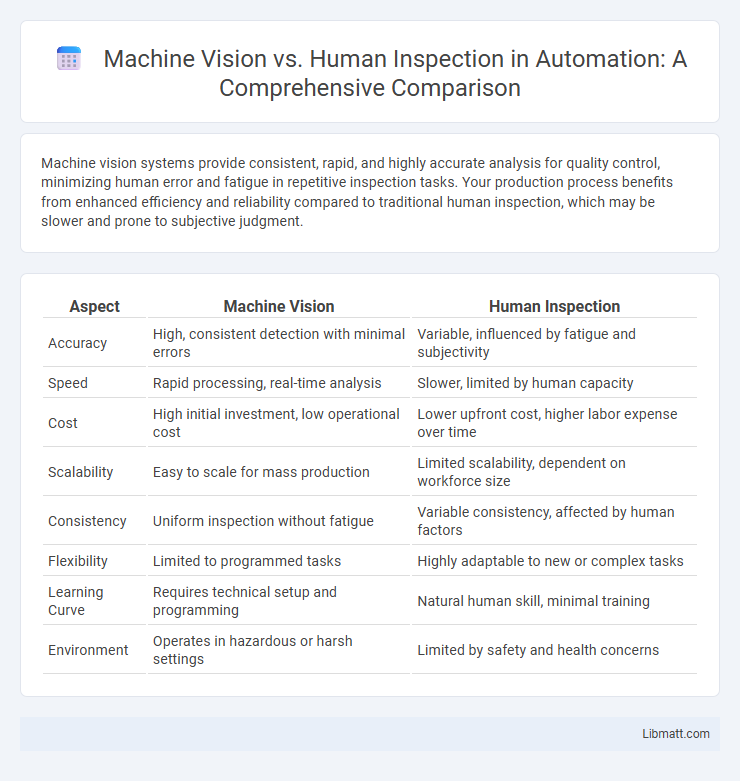

Machine vision systems provide consistent, rapid, and highly accurate analysis for quality control, minimizing human error and fatigue in repetitive inspection tasks. Your production process benefits from enhanced efficiency and reliability compared to traditional human inspection, which may be slower and prone to subjective judgment.

Table of Comparison

| Aspect | Machine Vision | Human Inspection |

|---|---|---|

| Accuracy | High, consistent detection with minimal errors | Variable, influenced by fatigue and subjectivity |

| Speed | Rapid processing, real-time analysis | Slower, limited by human capacity |

| Cost | High initial investment, low operational cost | Lower upfront cost, higher labor expense over time |

| Scalability | Easy to scale for mass production | Limited scalability, dependent on workforce size |

| Consistency | Uniform inspection without fatigue | Variable consistency, affected by human factors |

| Flexibility | Limited to programmed tasks | Highly adaptable to new or complex tasks |

| Learning Curve | Requires technical setup and programming | Natural human skill, minimal training |

| Environment | Operates in hazardous or harsh settings | Limited by safety and health concerns |

Understanding Machine Vision and Human Inspection

Machine vision employs advanced cameras and image processing algorithms to perform rapid, consistent inspections in manufacturing environments, detecting defects with precision beyond human capability. Human inspection relies on visual acuity, experience, and cognitive skills to identify anomalies, offering flexibility and judgment in complex scenarios where contextual understanding is crucial. Combining machine vision's speed and accuracy with human intuition enhances overall quality control effectiveness in diverse industrial applications.

Key Differences Between Machine Vision and Human Inspection

Machine vision systems offer consistent, high-speed inspection with precise image processing algorithms, enabling detection of minute defects that may be missed by human inspection. Humans excel in pattern recognition, adaptability, and judgment in complex or ambiguous scenarios where contextual understanding is required. The key differences lie in accuracy, repeatability, and fatigue resistance of machine vision versus the cognitive flexibility and intuitive decision-making capabilities inherent to human inspectors.

Accuracy: Machine Vision vs Human Capabilities

Machine vision systems deliver higher accuracy by consistently detecting defects and variations beyond human visual limits, utilizing advanced image processing algorithms and artificial intelligence. Human inspection remains prone to fatigue and subjectivity, which can lead to missed errors and inconsistent quality control. Your quality assurance process benefits from integrating machine vision to achieve superior precision and reliability compared to manual inspection.

Speed and Efficiency in Quality Control

Machine vision systems process images with speed reaching thousands of inspections per minute, significantly outperforming human inspection rates limited by fatigue and attention span. Automated quality control reduces error rates by consistently applying precise algorithms, enhancing efficiency across high-volume manufacturing lines. Human inspection remains valuable for complex judgments but lacks the scalability and rapid throughput enabled by advanced machine vision technology.

Adaptability to Complex Inspection Tasks

Machine vision systems excel at consistent, high-speed inspection of repetitive tasks but often struggle with complex, variable defects that require contextual understanding. Human inspection offers superior adaptability in identifying subtle anomalies and interpreting ambiguous scenarios due to cognitive flexibility and experience. Combining machine vision with human oversight enhances accuracy by leveraging automation's efficiency and human adaptability in complex inspection tasks.

Cost Implications and ROI Analysis

Machine vision systems require a higher initial investment compared to human inspection, but deliver significant cost savings through increased speed, accuracy, and reduced labor expenses. ROI analysis often shows rapid payback periods due to minimized product defects, lower rework costs, and consistent operational efficiency. Over time, machine vision enhances scalability and reduces variability, offering superior long-term financial benefits compared to manual inspection.

Consistency and Error Rates Comparison

Machine vision systems offer superior consistency in inspection tasks by eliminating human variability caused by fatigue or subjective judgment, resulting in significantly lower error rates. Studies show that machine vision can achieve error rates below 1% in quality control applications, whereas human inspectors commonly exhibit error rates ranging from 5% to 10%. The repeatability and precision of machine vision make it the preferred choice for industries requiring high accuracy and uniformity in defect detection.

Integration with Automated Manufacturing Systems

Machine vision systems seamlessly integrate with automated manufacturing systems by providing real-time, high-precision inspection data that improves process control and reduces human error. Unlike human inspection, these systems can continuously monitor production lines without fatigue, ensuring consistent quality and faster response to defects. Your manufacturing operations benefit from enhanced efficiency and reduced downtime through the synergy of machine vision and automation technologies.

Situational Suitability: When to Choose Each Approach

Machine vision excels in high-speed, repetitive tasks requiring precise defect detection and consistency, making it ideal for automated manufacturing environments and quality control of uniform products. Human inspection is better suited for complex, variable scenarios where judgment, adaptability, and nuanced perception are necessary, such as evaluating aesthetic qualities or detecting subtle anomalies. Choosing between the two depends on factors like inspection speed requirements, product complexity, cost constraints, and the need for subjective evaluation.

Future Trends in Inspection Technologies

Future trends in inspection technologies emphasize the integration of advanced machine vision systems powered by artificial intelligence and deep learning algorithms, enabling real-time defect detection with higher accuracy than traditional human inspection. Emerging innovations include hyperspectral imaging and 3D vision, enhancing the capability to identify microscopic flaws and ensuring superior quality control in manufacturing processes. These technologies are expected to reduce inspection times, lower operational costs, and improve consistency across various industries such as automotive, electronics, and pharmaceuticals.

Machine Vision vs Human Inspection Infographic

libmatt.com

libmatt.com