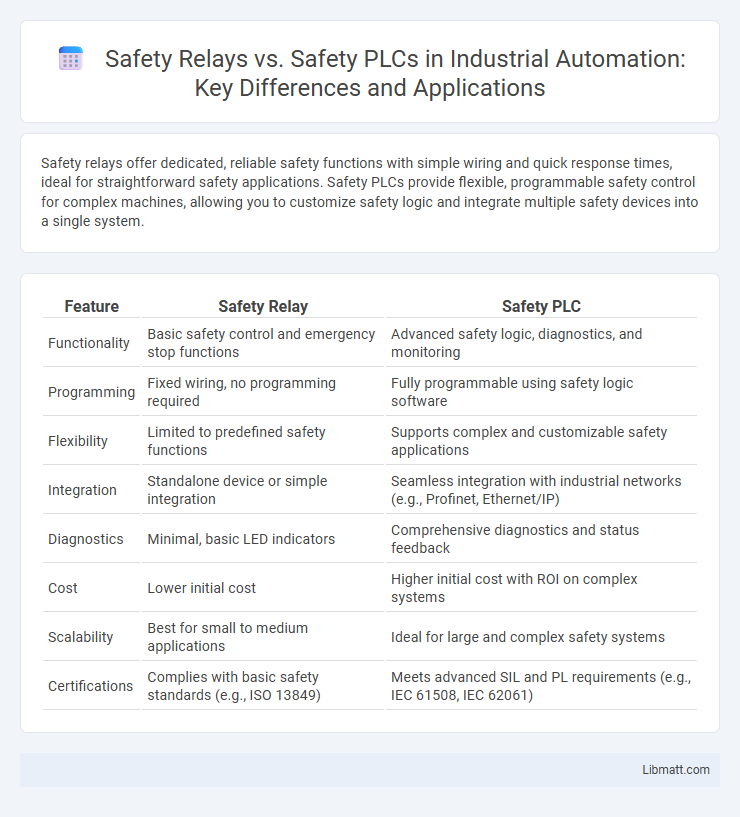

Safety relays offer dedicated, reliable safety functions with simple wiring and quick response times, ideal for straightforward safety applications. Safety PLCs provide flexible, programmable safety control for complex machines, allowing you to customize safety logic and integrate multiple safety devices into a single system.

Table of Comparison

| Feature | Safety Relay | Safety PLC |

|---|---|---|

| Functionality | Basic safety control and emergency stop functions | Advanced safety logic, diagnostics, and monitoring |

| Programming | Fixed wiring, no programming required | Fully programmable using safety logic software |

| Flexibility | Limited to predefined safety functions | Supports complex and customizable safety applications |

| Integration | Standalone device or simple integration | Seamless integration with industrial networks (e.g., Profinet, Ethernet/IP) |

| Diagnostics | Minimal, basic LED indicators | Comprehensive diagnostics and status feedback |

| Cost | Lower initial cost | Higher initial cost with ROI on complex systems |

| Scalability | Best for small to medium applications | Ideal for large and complex safety systems |

| Certifications | Complies with basic safety standards (e.g., ISO 13849) | Meets advanced SIL and PL requirements (e.g., IEC 61508, IEC 62061) |

Introduction to Safety Relays and Safety PLCs

Safety relays are dedicated devices designed to monitor safety functions by quickly detecting faults and initiating emergency stops in machinery, ensuring compliance with safety standards like ISO 13849. Safety PLCs (Programmable Logic Controllers) offer flexible, programmable safety control solutions that integrate complex safety logic and diagnostics within industrial automation systems. Choosing between a safety relay and a safety PLC depends on your system's complexity, required scalability, and the need for advanced safety functions.

Key Functions of Safety Relays

Safety relays provide reliable monitoring and control for emergency stop circuits, safety gates, and light curtains, ensuring immediate machine shutdown in hazardous situations. These devices perform critical functions such as fault detection, self-monitoring, and redundancy to prevent failures in safety systems. Unlike Safety PLCs, safety relays deliver straightforward, time-tested hardware solutions for specific safety functions without complex programming requirements.

Core Features of Safety PLCs

Safety PLCs integrate programmable logic for advanced control, diagnostics, and monitoring functions, offering flexible configuration and scalability compared to fixed-function safety relays. They support complex safety protocols, self-testing, and communication with other systems via industrial networks, enhancing system reliability and compliance with international safety standards like IEC 61508 and ISO 13849. Safety PLCs also provide real-time data logging and fault diagnostics, enabling predictive maintenance and reducing downtime in critical industrial applications.

How Safety Relays Work

Safety relays operate by continuously monitoring safety-critical inputs such as emergency stop buttons, light curtains, or safety mats to ensure proper functionality and prevent hazardous machine operation. When a fault or unsafe condition is detected, the safety relay instantaneously interrupts power to hazardous equipment, providing a fail-safe response to protect operators and machinery. Your industrial automation system benefits from safety relays by achieving reliable, real-time safety monitoring with straightforward wiring and diagnostics compared to more complex Safety PLC systems.

How Safety PLCs Operate

Safety PLCs operate by continuously monitoring inputs from sensors and safety devices, processing this data through embedded safety logic, and controlling outputs to ensure machinery stops or operates safely during hazardous conditions. These programmable controllers use redundant systems and diagnostic checks to achieve high reliability and meet stringent safety standards like SIL and PL. Your use of Safety PLCs enables flexible, scalable safety solutions that integrate complex safety functions beyond the capabilities of traditional safety relays.

Advantages of Safety Relays

Safety relays offer simplicity, reliability, and cost-effectiveness for dedicated safety functions in industrial automation. They provide fast response times and are ideal for applications requiring straightforward monitoring of emergency stops, light curtains, and safety gates. Your system benefits from easier diagnostics and compliance with safety standards through the inherent redundancy and fail-safe design of safety relays.

Benefits of Safety PLCs

Safety PLCs offer enhanced flexibility and scalability compared to safety relays, enabling integration with complex automation systems and easier modifications through software updates. They provide advanced diagnostics and real-time monitoring capabilities, improving system reliability and reducing downtime. The ability to handle multiple safety functions within a single device reduces wiring complexity and installation costs, making Safety PLCs ideal for modern industrial environments.

Safety Relay vs Safety PLC: Application Scenarios

Safety relays are ideal for simple safety functions such as emergency stop circuits, light curtains, and safety door monitoring in small to medium-sized machinery. Safety PLCs excel in complex applications requiring flexible programmable safety logic, such as coordinating multiple safety zones and integrating with standard control systems in larger industrial plants. Selecting between safety relays and safety PLCs depends on the required safety function complexity, system scalability, and automation integration needs.

Cost Comparison: Safety Relays vs Safety PLCs

Safety relays typically offer a lower initial cost compared to safety PLCs, making them ideal for simple safety functions and smaller systems. Safety PLCs, while more expensive upfront, provide greater flexibility, scalability, and advanced diagnostics, which can reduce long-term maintenance and upgrade expenses. Your choice between the two should balance upfront investment with ongoing operational costs and system complexity.

Choosing the Right Safety Solution for Your System

Choosing the right safety solution for your system depends on factors such as complexity, scalability, and budget. Safety relays provide reliable, cost-effective protection for simple, single-function safety applications, while Safety PLCs offer advanced flexibility and programmability for complex, multi-function safety systems. Evaluating system requirements, including the number of safety inputs and integration capabilities, ensures optimal selection between safety relays and Safety PLCs for enhanced machine safety compliance and performance.

Safety Relay vs Safety PLC Infographic

libmatt.com

libmatt.com