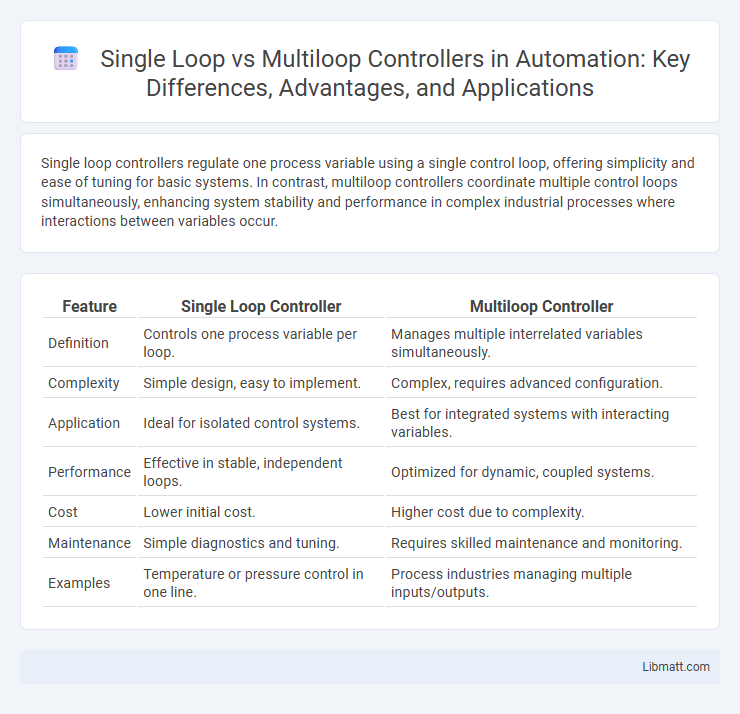

Single loop controllers regulate one process variable using a single control loop, offering simplicity and ease of tuning for basic systems. In contrast, multiloop controllers coordinate multiple control loops simultaneously, enhancing system stability and performance in complex industrial processes where interactions between variables occur.

Table of Comparison

| Feature | Single Loop Controller | Multiloop Controller |

|---|---|---|

| Definition | Controls one process variable per loop. | Manages multiple interrelated variables simultaneously. |

| Complexity | Simple design, easy to implement. | Complex, requires advanced configuration. |

| Application | Ideal for isolated control systems. | Best for integrated systems with interacting variables. |

| Performance | Effective in stable, independent loops. | Optimized for dynamic, coupled systems. |

| Cost | Lower initial cost. | Higher cost due to complexity. |

| Maintenance | Simple diagnostics and tuning. | Requires skilled maintenance and monitoring. |

| Examples | Temperature or pressure control in one line. | Process industries managing multiple inputs/outputs. |

Introduction to Process Controllers

Process controllers regulate industrial systems by continuously adjusting variables to maintain desired setpoints. Single loop controllers manage one control loop, directly processing feedback from one sensor, while multiloop controllers coordinate multiple loops, optimizing complex processes simultaneously. Your choice between single loop and multiloop controllers depends on the complexity of the system and the level of process integration required.

Understanding Single Loop Controllers

Single loop controllers regulate one process variable using a single feedback loop, making them ideal for straightforward control tasks such as temperature or pressure. These controllers continuously compare the measured value to the setpoint and adjust the output to minimize error, ensuring process stability and accuracy. Your operations benefit from the simplicity and reliability of single loop controllers, especially in systems requiring precise, focused control.

Exploring Multiloop Controllers

Multiloop controllers manage multiple control loops simultaneously, enhancing system stability and performance in complex processes where single-loop controllers fall short. They coordinate interactions between various process variables, reducing oscillations and improving response times compared to independent single loop configurations. Optimizing your system with multiloop controllers ensures better handling of multivariable interactions and achieves precise control across integrated processes.

Key Differences Between Single and Multiloop Controllers

Single loop controllers regulate one process variable with a single feedback loop, ensuring straightforward operation and ease of tuning. Multiloop controllers manage multiple interrelated variables simultaneously, optimizing complex systems by coordinating several feedback loops for enhanced stability and performance. Your choice depends on system complexity, with single loop controllers ideal for simpler tasks and multiloop controllers suited for processes requiring integrated control.

Advantages of Single Loop Control Systems

Single loop control systems offer simplicity and ease of implementation, making them cost-effective for basic process control tasks. Their straightforward design ensures faster response times and easier troubleshooting, improving overall system reliability. You benefit from reduced complexity, which minimizes maintenance efforts and enhances operational efficiency in many industrial applications.

Benefits of Multiloop Control Systems

Multiloop control systems enhance process stability and accuracy by managing multiple variables simultaneously, reducing the risk of disturbances affecting overall performance. These systems improve efficiency through coordinated control actions, optimizing resource use and minimizing energy consumption. Your operations benefit from increased robustness and flexibility, enabling better adaptation to complex industrial environments compared to single loop controllers.

Common Applications of Single Loop Controllers

Single loop controllers are commonly used in applications where precise control of a single process variable, such as temperature, pressure, or flow rate, is required. Industries like chemical processing, HVAC systems, and water treatment plants rely on single loop controllers for straightforward, reliable regulation of individual parameters. Your system benefits from the simplicity and cost-effectiveness of single loop controllers in scenarios where complex interactions between multiple variables are minimal.

Typical Uses of Multiloop Controllers

Multiloop controllers are typically used in complex industrial processes where multiple interacting variables need to be controlled simultaneously, such as in chemical plants, refineries, and power generation systems. They enhance system stability and performance by coordinating several single-loop controllers to manage interrelated control loops effectively. Your process benefits from multiloop controllers when precise regulation of temperature, pressure, flow, and other parameters across different stages is critical for operational efficiency.

Selection Criteria: Which Controller to Choose?

Single loop controllers are ideal for simple processes with stable dynamics and minimal interaction between control variables, making them easier to implement and tune. Multiloop controllers suit complex systems requiring coordinated control of multiple interacting variables, offering improved performance in processes with significant coupling and disturbances. Selection depends on process complexity, interaction degree, and desired control precision, with single loop preferred for straightforward tasks and multiloop for advanced multi-variable control scenarios.

Conclusion: Optimal Controller for Your Process

Choosing between a Single Loop and Multiloop Controller depends on the complexity and interaction level of your process variables. Single Loop Controllers offer simplicity and cost-effectiveness for independent control tasks, while Multiloop Controllers excel in managing multivariable processes with strong interactions, ensuring stability and improved performance. For optimal control tailored to your process demands, Multiloop Controllers provide superior adaptability and precision in dynamic industrial environments.

Single Loop vs Multiloop Controller Infographic

libmatt.com

libmatt.com