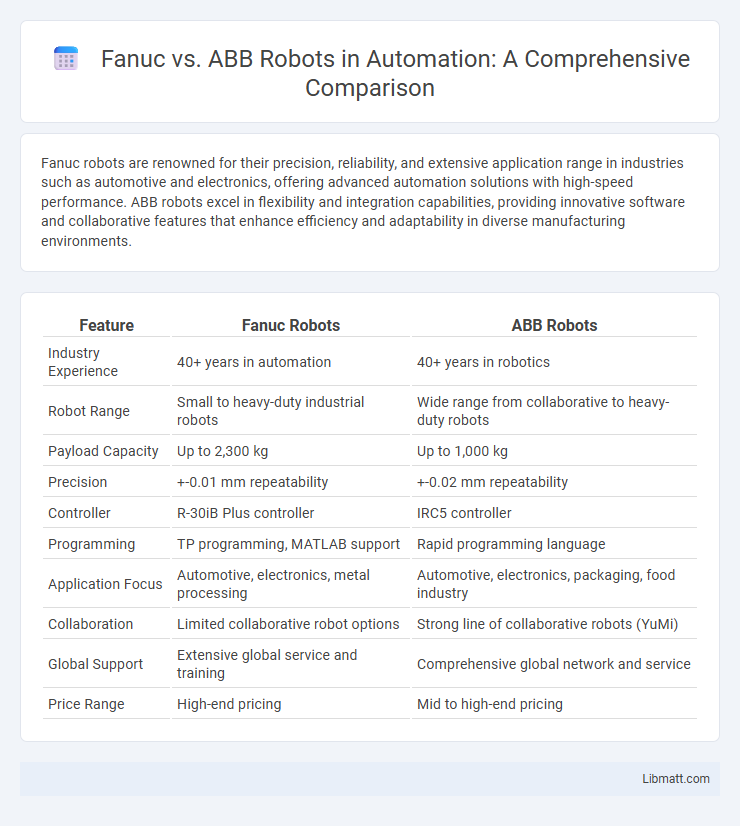

Fanuc robots are renowned for their precision, reliability, and extensive application range in industries such as automotive and electronics, offering advanced automation solutions with high-speed performance. ABB robots excel in flexibility and integration capabilities, providing innovative software and collaborative features that enhance efficiency and adaptability in diverse manufacturing environments.

Table of Comparison

| Feature | Fanuc Robots | ABB Robots |

|---|---|---|

| Industry Experience | 40+ years in automation | 40+ years in robotics |

| Robot Range | Small to heavy-duty industrial robots | Wide range from collaborative to heavy-duty robots |

| Payload Capacity | Up to 2,300 kg | Up to 1,000 kg |

| Precision | +-0.01 mm repeatability | +-0.02 mm repeatability |

| Controller | R-30iB Plus controller | IRC5 controller |

| Programming | TP programming, MATLAB support | Rapid programming language |

| Application Focus | Automotive, electronics, metal processing | Automotive, electronics, packaging, food industry |

| Collaboration | Limited collaborative robot options | Strong line of collaborative robots (YuMi) |

| Global Support | Extensive global service and training | Comprehensive global network and service |

| Price Range | High-end pricing | Mid to high-end pricing |

Introduction to Fanuc and ABB Robots

Fanuc Robotics, a Japanese leader in industrial automation, specializes in high-precision robotic arms widely used in manufacturing and CNC machining industries. ABB Robotics, a division of the Swiss-Swedish multinational ABB Group, excels in collaborative robots and automation solutions for diverse sectors such as automotive, electronics, and pharmaceuticals. Both companies feature advanced robot controllers, extensive product lines, and global support networks, making them key players in industrial robot innovation and deployment.

Company Backgrounds: Fanuc vs ABB

Fanuc, founded in 1972 in Japan, is a global leader specializing in CNC systems, robotics, and factory automation, recognized for its high reliability and precision in industrial robotics. ABB, established in 1988 through a merger of Asea and Brown Boveri, is a Swiss-Swedish multinational corporation with a strong emphasis on electrification, robotics, and automation technologies for diverse industries worldwide. Your choice between Fanuc and ABB robots may depend on the specific industry focus, with Fanuc excelling in manufacturing robotics and ABB offering integrated automation solutions.

Product Range and Robot Types

Fanuc offers a comprehensive product range that includes articulated robots, SCARA robots, and collaborative robots designed for diverse industrial applications like automotive, electronics, and metal fabrication. ABB's robot portfolio features a variety of articulated robots, delta robots, and collaborative robots known for precision and flexibility in manufacturing sectors such as automotive, food and beverage, and pharmaceuticals. Both companies provide specialized robots tailored for tasks including welding, painting, assembly, and material handling to meet varied automation needs.

Key Features and Technologies

Fanuc robots are known for their advanced motion control systems, high-speed precision, and extensive use of artificial intelligence for adaptive automation, making them ideal for complex manufacturing tasks. ABB robots excel with their integrated digital solutions, superior payload capacity, and enhanced safety features such as collision detection, optimized for heavy-duty industrial applications. Both brands offer robust connectivity options and user-friendly interfaces, with Fanuc emphasizing ease of programming and ABB focusing on seamless integration into Industry 4.0 environments.

Performance Comparison

Fanuc robots deliver unparalleled precision and speed, boasting advanced motion control systems that excel in high-volume manufacturing environments. ABB robots offer exceptional flexibility and energy efficiency, ideal for complex tasks requiring adaptive automation and reduced operational costs. Your choice depends on prioritizing Fanuc's robust performance in repetitive tasks or ABB's innovative capabilities for versatile industrial applications.

Ease of Integration and Programming

Fanuc robots offer a user-friendly interface with extensive support for integration through their proprietary software, facilitating seamless deployment in manufacturing environments. ABB robots feature the RobotStudio simulation tool, which enables offline programming and easy adaptation to complex workflows, enhancing overall productivity. Both brands provide robust APIs and compatibility with industry-standard protocols, streamlining programming and system integration processes.

Industry Applications

Fanuc robots excel in automotive manufacturing, electronics assembly, and metal fabrication due to their high precision and reliability. ABB robots dominate in food processing, pharmaceuticals, and logistics with advanced motion control and flexible automation solutions. Your choice between Fanuc and ABB should consider specific industry requirements like speed, payload, and integration capabilities.

Reliability and Maintenance

Fanuc robots are renowned for their exceptional reliability, offering extended operational uptime with minimal breakdowns, which is supported by a robust global network for fast maintenance and spare part availability. ABB robots emphasize ease of maintenance with user-friendly diagnostics and modular components that reduce downtime and streamline repairs. Your choice between Fanuc and ABB should consider the criticality of continuous operation versus quick serviceability in your robotic applications.

Cost and Return on Investment

Fanuc robots often present a lower initial cost compared to ABB robots, making them attractive for budget-sensitive projects. ABB robots, while generally more expensive upfront, offer advanced automation features and energy efficiency that contribute to higher long-term return on investment (ROI). Evaluating total cost of ownership, including maintenance and productivity gains, is crucial for determining which robot system yields the best financial outcome.

Market Presence and Customer Support

Fanuc leads the industrial robot market with a strong global presence, boasting extensive service centers and a vast customer support network across key manufacturing regions such as automotive and electronics. ABB maintains a significant footprint in Europe, Asia, and the Americas, emphasizing tailored customer service with remote diagnostics and comprehensive training programs. Both companies prioritize reliability and rapid response times, ensuring minimized downtime and optimized production efficiency for diverse industrial applications.

Fanuc vs ABB Robots Infographic

libmatt.com

libmatt.com