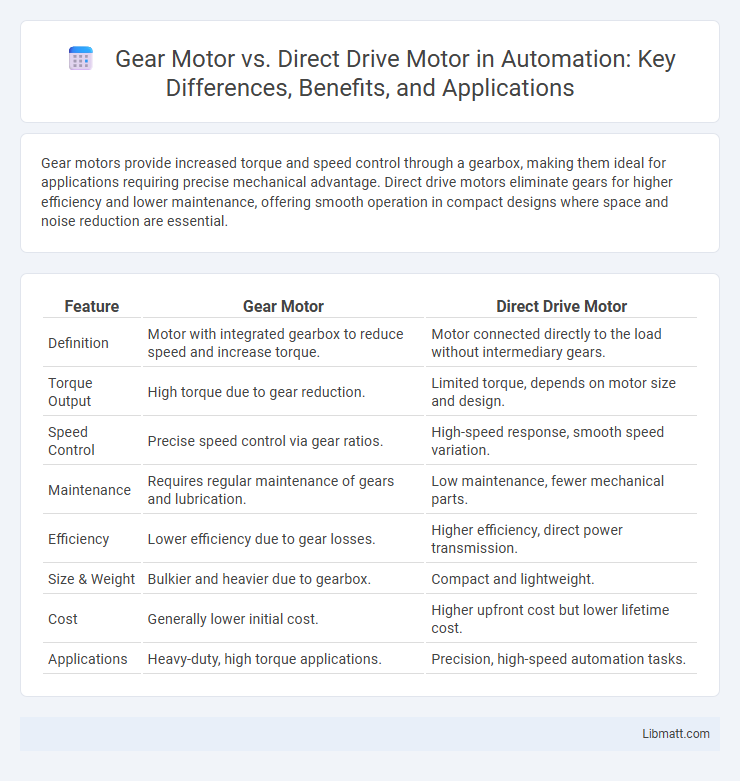

Gear motors provide increased torque and speed control through a gearbox, making them ideal for applications requiring precise mechanical advantage. Direct drive motors eliminate gears for higher efficiency and lower maintenance, offering smooth operation in compact designs where space and noise reduction are essential.

Table of Comparison

| Feature | Gear Motor | Direct Drive Motor |

|---|---|---|

| Definition | Motor with integrated gearbox to reduce speed and increase torque. | Motor connected directly to the load without intermediary gears. |

| Torque Output | High torque due to gear reduction. | Limited torque, depends on motor size and design. |

| Speed Control | Precise speed control via gear ratios. | High-speed response, smooth speed variation. |

| Maintenance | Requires regular maintenance of gears and lubrication. | Low maintenance, fewer mechanical parts. |

| Efficiency | Lower efficiency due to gear losses. | Higher efficiency, direct power transmission. |

| Size & Weight | Bulkier and heavier due to gearbox. | Compact and lightweight. |

| Cost | Generally lower initial cost. | Higher upfront cost but lower lifetime cost. |

| Applications | Heavy-duty, high torque applications. | Precision, high-speed automation tasks. |

Introduction to Gear Motors and Direct Drive Motors

Gear motors combine electric motors with gear systems to deliver high torque at low speeds, making them ideal for heavy-duty applications requiring precise control. Direct drive motors eliminate the need for gears by connecting the motor directly to the load, resulting in higher efficiency, reduced maintenance, and smoother operation. Understanding the key differences between these motor types helps you choose the optimal solution for your specific mechanical and performance requirements.

Key Differences Between Gear Motors and Direct Drive Motors

Gear motors incorporate a gearbox to reduce speed and increase torque, making them ideal for applications requiring high torque at low speeds. Direct drive motors eliminate the need for a gearbox by connecting the motor shaft directly to the load, resulting in higher efficiency, reduced maintenance, and more precise control. The key differences lie in mechanical complexity, torque output, speed range, and maintenance requirements, with gear motors suited for high-torque simplicity and direct drive motors favored for efficiency and precision.

How Gear Motors Work

Gear motors work by combining an electric motor with a gear reduction system to increase torque while reducing speed. The gears transfer mechanical energy efficiently, allowing the motor to deliver precise control in applications requiring high torque at low speeds. This mechanism enables your equipment to perform tasks demanding powerful, controlled motion without overloading the motor.

How Direct Drive Motors Operate

Direct drive motors operate by eliminating gears and connecting the rotor directly to the load, resulting in increased efficiency and reduced mechanical losses. These motors use powerful permanent magnets and precise electronic controls to provide smooth torque and high acceleration from standstill. The absence of gears decreases maintenance needs and enhances reliability in applications such as robotics, industrial automation, and electric vehicles.

Performance and Efficiency Comparison

Gear motors provide enhanced torque and speed control by utilizing gear reductions, which improve mechanical advantage but can introduce energy loss due to friction within the gear train. Direct drive motors deliver superior efficiency by eliminating intermediary components, resulting in less mechanical loss and more precise performance due to the motor being directly coupled to the load. Your application's performance demands and energy efficiency targets will determine whether the controlled torque of gear motors or the high-efficiency, low-maintenance operation of direct drive motors is more suitable.

Applications of Gear Motors

Gear motors are widely used in applications requiring high torque and precise speed control, such as conveyor systems, packaging machinery, and robotics. Their ability to reduce speed while increasing torque makes them ideal for heavy-duty tasks in industrial automation, material handling, and automotive equipment. Common sectors utilizing gear motors include manufacturing plants, agricultural machinery, and HVAC systems.

Applications of Direct Drive Motors

Direct drive motors are ideal for applications requiring high precision and smooth motion control, such as robotics, CNC machines, and medical devices. Their design eliminates gears, reducing maintenance and minimizing mechanical losses, which enhances reliability and efficiency in automated systems. You benefit from quieter operation and faster response times, making direct drive motors perfect for demanding tasks like packaging machinery and semiconductor manufacturing.

Advantages and Disadvantages: Gear Motors

Gear motors offer higher torque output and precise speed control by combining an electric motor with a gear reducer, making them ideal for heavy-duty applications. Their complexity and additional components increase maintenance needs and potential mechanical wear compared to direct drive motors. Efficiency losses due to gear friction and noise generation are common disadvantages in gear motor systems.

Pros and Cons: Direct Drive Motors

Direct drive motors offer high efficiency, low maintenance, and reduced noise due to the elimination of gears, making them ideal for precision applications and smooth operation. However, they tend to have lower torque output compared to gear motors and can be more expensive upfront. Your choice depends on whether you prioritize maintenance simplicity and efficiency over torque and initial cost.

How to Choose Between Gear Motor and Direct Drive Motor

Choosing between a gear motor and a direct drive motor depends on factors such as torque requirements, speed control, and space constraints. Gear motors provide high torque at low speeds through a geared reduction, making them suitable for applications needing increased torque and precise speed control. Direct drive motors offer higher efficiency with fewer mechanical parts, ideal for compact designs where minimal maintenance and smooth operation are priorities, helping you optimize your machine's performance based on your specific needs.

Gear Motor vs Direct Drive Motor Infographic

libmatt.com

libmatt.com