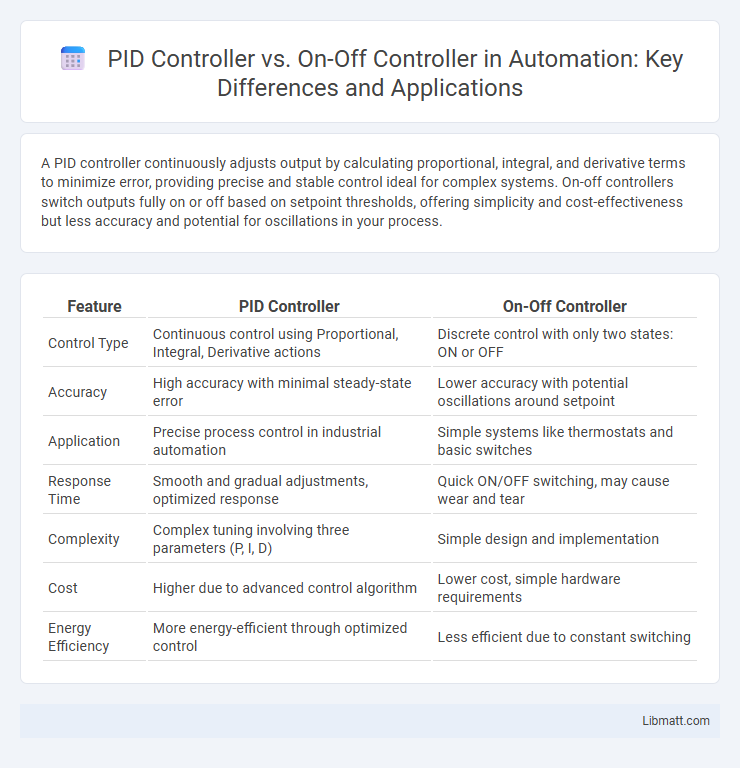

A PID controller continuously adjusts output by calculating proportional, integral, and derivative terms to minimize error, providing precise and stable control ideal for complex systems. On-off controllers switch outputs fully on or off based on setpoint thresholds, offering simplicity and cost-effectiveness but less accuracy and potential for oscillations in your process.

Table of Comparison

| Feature | PID Controller | On-Off Controller |

|---|---|---|

| Control Type | Continuous control using Proportional, Integral, Derivative actions | Discrete control with only two states: ON or OFF |

| Accuracy | High accuracy with minimal steady-state error | Lower accuracy with potential oscillations around setpoint |

| Application | Precise process control in industrial automation | Simple systems like thermostats and basic switches |

| Response Time | Smooth and gradual adjustments, optimized response | Quick ON/OFF switching, may cause wear and tear |

| Complexity | Complex tuning involving three parameters (P, I, D) | Simple design and implementation |

| Cost | Higher due to advanced control algorithm | Lower cost, simple hardware requirements |

| Energy Efficiency | More energy-efficient through optimized control | Less efficient due to constant switching |

Introduction to PID and On-Off Controllers

PID controllers continuously adjust the control output by calculating proportional, integral, and derivative terms based on the error signal, providing precise and stable system regulation. On-off controllers operate by switching the control output fully on or off once the process variable crosses a set threshold, resulting in simple but less accurate control with potential oscillations. Understanding these fundamental differences is crucial for selecting the appropriate control strategy in automation and process control applications.

How PID Controllers Work

PID controllers regulate system output by continuously calculating an error value as the difference between a desired setpoint and a measured process variable. They apply corrective control based on proportional, integral, and derivative terms, which adjust the output to minimize error over time and reduce oscillations. This precise modulation enhances system stability and response compared to the simpler, binary nature of On-Off controllers.

How On-Off Controllers Function

On-Off controllers operate by switching the output fully on or off when the process variable crosses a set threshold, creating a simple binary control method. They are ideal for systems where precise control is less critical, often used in thermostats or basic heating devices. Your choice between On-Off and PID controllers should consider the need for stable and smooth control versus the simplicity and cost-effectiveness of On-Off operation.

Key Differences Between PID and On-Off Controllers

PID controllers continuously adjust the output based on proportional, integral, and derivative terms to maintain precise control, while on-off controllers operate with simple binary signals turning the system fully on or off. The PID controller minimizes steady-state error and reduces oscillations by predicting system behavior, whereas the on-off controller typically causes frequent switching and potential wear due to its abrupt actions. Your choice between these controllers depends on the need for accuracy and smoothness versus simplicity and cost-effectiveness in the control process.

Advantages of PID Controllers

PID controllers offer precise control by continuously adjusting output based on proportional, integral, and derivative terms, which reduces steady-state error and minimizes overshoot compared to On-Off controllers. Your system benefits from smoother response and improved stability in processes requiring accurate temperature, pressure, or speed regulation. These controllers also adapt to changes in system dynamics, enhancing performance in complex industrial automation and control applications.

Advantages of On-Off Controllers

On-Off controllers offer simplicity and cost-effectiveness, making them ideal for basic temperature and pressure control applications where precision is less critical. Their straightforward operation enables fast switching between fully on and fully off states, reducing the complexity of installation and maintenance. On-Off controllers also provide reliable performance in systems with inherently slow dynamics or where continuous modulation is unnecessary.

Limitations of Each Control Method

PID controllers can struggle with system nonlinearities and require precise tuning to avoid overshoot or instability, which may complicate your control system design. On-off controllers often cause oscillations around the setpoint due to their binary nature, leading to wear on mechanical components and inefficient energy usage. Both methods have inherent limitations in response time and accuracy, making the choice dependent on the specific application requirements.

Typical Applications for PID Controllers

PID controllers are widely used in industrial processes requiring precise control, such as temperature regulation in HVAC systems, speed control in motors, and pressure control in chemical reactors. Their ability to continuously adjust the output based on proportional, integral, and derivative terms makes them ideal for applications demanding smooth and stable control. If your system experiences variable disturbances or requires fine-tuned adjustments, a PID controller is typically the preferred choice over an On-Off controller.

Typical Applications for On-Off Controllers

On-off controllers are typically used in applications where simple, binary control is sufficient, such as thermostats in residential heating systems, electric water heaters, and refrigeration units. These controllers maintain desired setpoints by switching the output fully on or off, making them ideal for systems with slow response times or where precise control is unnecessary. Your choice of an on-off controller suits environments requiring cost-effective, reliable, and straightforward control without the complexity of continuous modulation.

Choosing the Right Controller for Your System

Selecting the right controller depends on the system's complexity and precision requirements. PID controllers offer precise control by continuously adjusting output based on proportional, integral, and derivative terms, making them ideal for systems needing smooth and stable responses. On-off controllers provide simple, cost-effective control for systems tolerant to fluctuations, suitable for applications with less sensitivity to overshoot or steady-state error.

PID Controller vs On-Off Controller Infographic

libmatt.com

libmatt.com