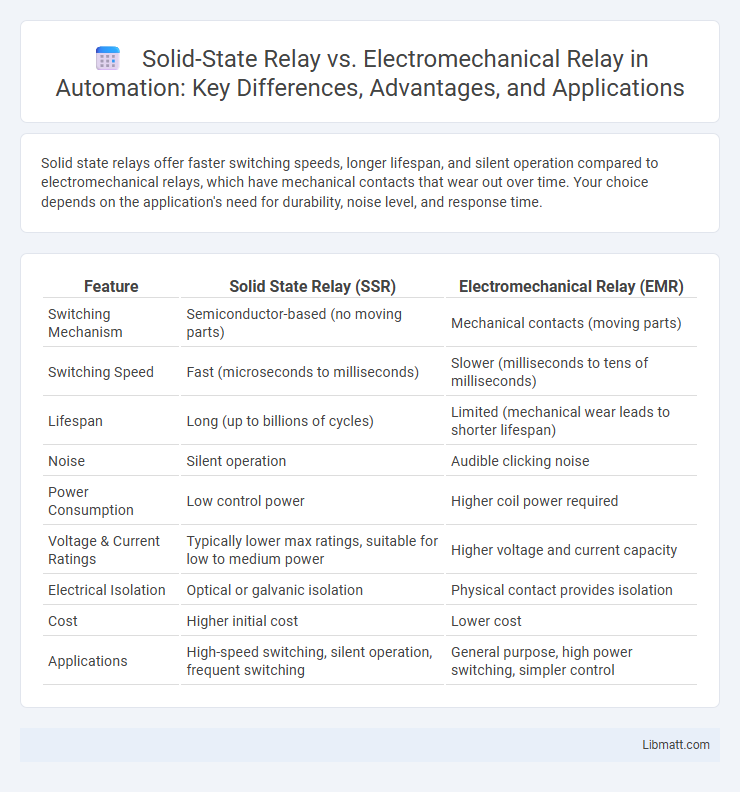

Solid state relays offer faster switching speeds, longer lifespan, and silent operation compared to electromechanical relays, which have mechanical contacts that wear out over time. Your choice depends on the application's need for durability, noise level, and response time.

Table of Comparison

| Feature | Solid State Relay (SSR) | Electromechanical Relay (EMR) |

|---|---|---|

| Switching Mechanism | Semiconductor-based (no moving parts) | Mechanical contacts (moving parts) |

| Switching Speed | Fast (microseconds to milliseconds) | Slower (milliseconds to tens of milliseconds) |

| Lifespan | Long (up to billions of cycles) | Limited (mechanical wear leads to shorter lifespan) |

| Noise | Silent operation | Audible clicking noise |

| Power Consumption | Low control power | Higher coil power required |

| Voltage & Current Ratings | Typically lower max ratings, suitable for low to medium power | Higher voltage and current capacity |

| Electrical Isolation | Optical or galvanic isolation | Physical contact provides isolation |

| Cost | Higher initial cost | Lower cost |

| Applications | High-speed switching, silent operation, frequent switching | General purpose, high power switching, simpler control |

Introduction to Relays: Understanding the Basics

Solid State Relays (SSRs) use semiconductor components to switch electrical loads without moving parts, offering faster switching times and longer lifespan than Electromechanical Relays (EMRs), which rely on physical contacts and coils to control circuits. SSRs provide silent operation and resistance to mechanical wear, making them ideal for high-speed or high-cycle applications, while EMRs are often preferred for their simplicity and lower initial cost in less demanding environments. Understanding the fundamental differences in operation and construction helps you select the appropriate relay type for your specific electrical control needs.

What is a Solid State Relay?

A Solid State Relay (SSR) is an electronic switching device that uses semiconductor components to switch electrical loads without moving parts, providing faster operation and longer lifespan compared to Electromechanical Relays (EMRs). SSRs offer silent switching, resistance to shock and vibration, and improved reliability in applications requiring frequent on/off cycles. Your choice of SSR can enhance system performance by reducing maintenance and improving switching speed in industrial automation or control systems.

What is an Electromechanical Relay?

An electromechanical relay (EMR) is a switch that uses an electromagnetic coil to mechanically operate contacts, enabling the control of high voltage circuits with a low voltage signal. It features physical moving parts, such as the armature and contacts, which open or close the circuit when energized. EMRs are widely used for their reliability, electrical isolation, and ability to handle high current loads in industrial and automotive applications.

Key Differences Between Solid State and Electromechanical Relays

Solid State Relays (SSRs) use semiconductor components to switch electrical loads, providing faster response times and longer lifespans compared to Electromechanical Relays (EMRs), which rely on mechanical moving parts. SSRs offer silent operation and greater resistance to shock and vibration, making them ideal for high-frequency switching applications, whereas EMRs are preferred for their simplicity and cost-effectiveness in lower switching cycles. Key differences include switching speed, noise level, durability, energy consumption, and susceptibility to physical wear, with SSRs excelling in precision and reliability under demanding conditions.

Performance and Reliability Comparison

Solid State Relays (SSRs) offer faster switching speeds and longer operational lifespans compared to Electromechanical Relays (EMRs), due to their absence of moving parts which reduces wear and tear. SSRs provide superior reliability in high-vibration and high-frequency switching applications, while EMRs can handle higher voltage spikes and have clearer physical isolation. The choice between SSRs and EMRs depends on the specific requirements for switching speed, durability, and electrical noise tolerance in industrial or commercial systems.

Applications: Where Each Relay Shines

Solid State Relays excel in applications requiring fast switching, silent operation, and enhanced durability, such as industrial automation, temperature control systems, and sensitive electronic devices. Electromechanical Relays are preferred in heavy-duty applications involving high inrush currents or where electrical isolation and visual contact indication are essential, like motor control and power distribution. Your choice depends on the need for long life and reliability in solid state or the robustness and simplicity offered by electromechanical relays.

Advantages of Solid State Relays

Solid State Relays (SSRs) offer significant advantages over Electromechanical Relays (EMRs) including faster switching speeds, longer operational life due to the absence of moving parts, and higher resistance to vibration and shock. SSRs provide silent operation and reduced electromagnetic interference, making them ideal for sensitive electronic applications. Their low power consumption and ability to switch at high frequencies enhance overall system efficiency in automation and industrial control systems.

Advantages of Electromechanical Relays

Electromechanical relays offer distinct advantages such as the ability to switch high voltage and high current loads with excellent isolation between control and load circuits due to their physical contact mechanism. Their simple construction leads to easier troubleshooting and typically lower costs compared to Solid State Relays (SSRs). Furthermore, electromechanical relays can handle overloads and transient voltages better, providing reliable operation in harsh or demanding electrical environments.

Choosing the Right Relay for Your Application

Selecting the right relay depends on factors like switching speed, load type, and durability; solid state relays (SSRs) offer faster switching and longer lifespan without mechanical wear, making them ideal for high-frequency or vibration-prone environments. Electromechanical relays (EMRs) provide cost-effective solutions for applications requiring high inrush current handling and electrical isolation. Understanding the specific load requirements, switching conditions, and environmental factors ensures optimal relay performance and system reliability.

Future Trends in Relay Technology

Future trends in relay technology emphasize the increasing adoption of Solid State Relays (SSRs) due to their enhanced durability, faster switching speeds, and reduced electromagnetic interference compared to Electromechanical Relays (EMRs). Advances in semiconductor materials like silicon carbide and gallium nitride are driving SSR performance improvements for high-voltage and high-temperature applications. Integration of smart sensors and IoT connectivity in relay designs enables predictive maintenance and real-time system monitoring, positioning SSRs as the preferred solution for modern industrial automation and smart grid systems.

Solid State Relay vs Electromechanical Relay Infographic

libmatt.com

libmatt.com