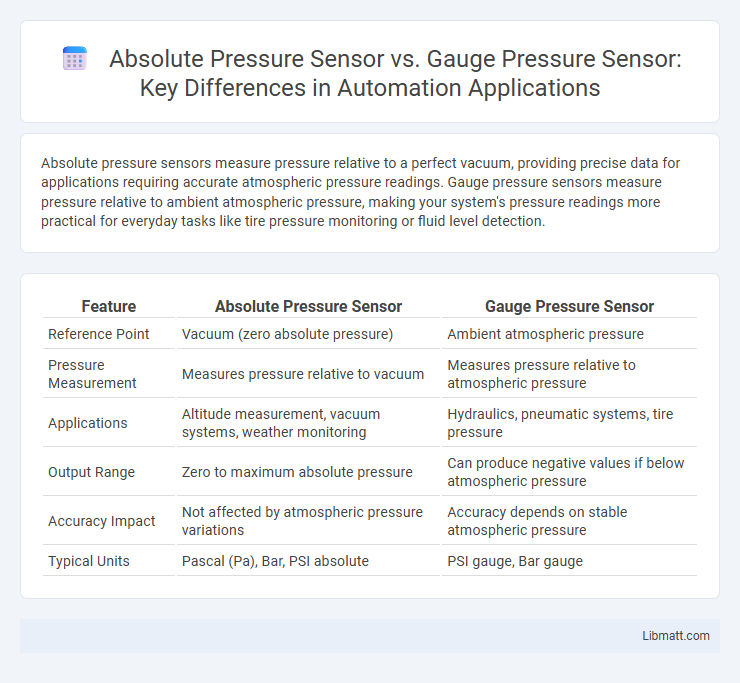

Absolute pressure sensors measure pressure relative to a perfect vacuum, providing precise data for applications requiring accurate atmospheric pressure readings. Gauge pressure sensors measure pressure relative to ambient atmospheric pressure, making your system's pressure readings more practical for everyday tasks like tire pressure monitoring or fluid level detection.

Table of Comparison

| Feature | Absolute Pressure Sensor | Gauge Pressure Sensor |

|---|---|---|

| Reference Point | Vacuum (zero absolute pressure) | Ambient atmospheric pressure |

| Pressure Measurement | Measures pressure relative to vacuum | Measures pressure relative to atmospheric pressure |

| Applications | Altitude measurement, vacuum systems, weather monitoring | Hydraulics, pneumatic systems, tire pressure |

| Output Range | Zero to maximum absolute pressure | Can produce negative values if below atmospheric pressure |

| Accuracy Impact | Not affected by atmospheric pressure variations | Accuracy depends on stable atmospheric pressure |

| Typical Units | Pascal (Pa), Bar, PSI absolute | PSI gauge, Bar gauge |

Understanding Pressure Sensors: Absolute vs Gauge

Absolute pressure sensors measure pressure relative to a perfect vacuum, providing readings that reflect the true pressure in a system. Gauge pressure sensors measure pressure relative to atmospheric pressure, indicating pressure differences above or below ambient levels. Understanding the distinction between absolute and gauge pressure sensors is crucial for accurate pressure monitoring in applications such as HVAC, automotive systems, and industrial processes.

What is an Absolute Pressure Sensor?

An Absolute Pressure Sensor measures pressure relative to a perfect vacuum (0 psi), providing precise readings essential for applications requiring accurate atmospheric or system pressure data. Unlike Gauge Pressure Sensors, which measure pressure relative to atmospheric pressure, absolute sensors deliver consistent results unaffected by changes in ambient pressure. You rely on Absolute Pressure Sensors for reliable monitoring in automotive, aviation, and industrial processes where exact pressure measurements are critical.

What is a Gauge Pressure Sensor?

A gauge pressure sensor measures pressure relative to the ambient atmospheric pressure, providing readings that indicate how much the pressure deviates from the surrounding air pressure. Unlike absolute pressure sensors, gauge sensors use the atmospheric pressure as a zero reference point, making them ideal for applications where the pressure difference matters, such as tire pressure monitoring. Your choice of a gauge pressure sensor is essential when monitoring systems exposed to changing atmospheric conditions.

Key Differences Between Absolute and Gauge Pressure Sensors

Absolute pressure sensors measure pressure relative to a perfect vacuum, providing precise readings essential for applications requiring accurate atmospheric or sealed environment measurements. Gauge pressure sensors measure pressure relative to ambient atmospheric pressure, making them suitable for monitoring fluid or gas pressure in systems exposed to the environment. Understanding the key differences between absolute and gauge pressure sensors helps you select the right sensor for your specific pressure measurement needs.

Applications of Absolute Pressure Sensors

Absolute pressure sensors are crucial in applications requiring precise measurement of pressure relative to a perfect vacuum, such as in aerospace for altitude determination and weather forecasting in meteorology. They are widely used in industrial processes involving vacuum systems, semiconductor manufacturing, and scientific research where accurate vacuum pressure monitoring is essential. Your choice of an absolute pressure sensor ensures reliable data collection in environments where gauge pressure sensors, which measure relative pressure, would be inadequate.

Applications of Gauge Pressure Sensors

Gauge pressure sensors are widely utilized in automotive systems, HVAC units, and hydraulic machinery to monitor pressure relative to atmospheric levels, ensuring optimal performance and safety. In medical devices such as blood pressure monitors and ventilators, gauge pressure sensors provide critical readings by measuring pressure differences within the human body. Industrial processes also rely on gauge pressure sensors for fluid control, leak detection, and pressurized vessel monitoring, benefiting from their accuracy in detecting pressure variations above or below ambient pressure.

Advantages of Absolute Pressure Sensors

Absolute pressure sensors provide precise measurements by referencing a perfect vacuum, ensuring accurate readings regardless of atmospheric changes. Their reliability in harsh environments and altitude variations makes them ideal for critical applications such as aerospace and weather monitoring. You benefit from consistent data output, which enhances system performance and safety in dynamic pressure conditions.

Advantages of Gauge Pressure Sensors

Gauge pressure sensors offer the advantage of measuring pressure relative to atmospheric pressure, which is crucial for applications where monitoring pressure differential is necessary, such as in HVAC systems and automotive tires. Their simpler construction typically leads to lower costs and easier integration compared to absolute pressure sensors, making them more accessible for everyday use. You benefit from reliable, direct readings of pressure above or below atmospheric levels, enhancing operational safety and efficiency in various industrial and consumer settings.

How to Choose Between Absolute and Gauge Pressure Sensors

Choosing between absolute and gauge pressure sensors depends on the reference pressure requirement and the application environment. Absolute pressure sensors measure pressure relative to a perfect vacuum, making them ideal for applications needing precise atmospheric or vacuum pressure monitoring, while gauge pressure sensors measure relative to ambient atmospheric pressure, suited for processes where only pressure differences matter. Consider factors such as the need for accuracy under varying atmospheric conditions, sensor calibration drift, and the specific pressure range to ensure optimal sensor selection.

Summary and Best Practices for Pressure Sensor Selection

Absolute Pressure Sensors measure pressure relative to a perfect vacuum, providing accurate readings in applications where atmospheric pressure variations impact results, while Gauge Pressure Sensors measure pressure relative to ambient atmospheric pressure, making them ideal for processes where pressure changes above atmospheric pressure are crucial. Selecting the right sensor depends on your specific requirements, such as environmental conditions, required accuracy, and the reference point for pressure measurement. Best practices include assessing the sensor's pressure range, compatibility with media, and environmental factors to ensure reliable and precise performance in your application.

Absolute Pressure Sensor vs Gauge Pressure Sensor Infographic

libmatt.com

libmatt.com