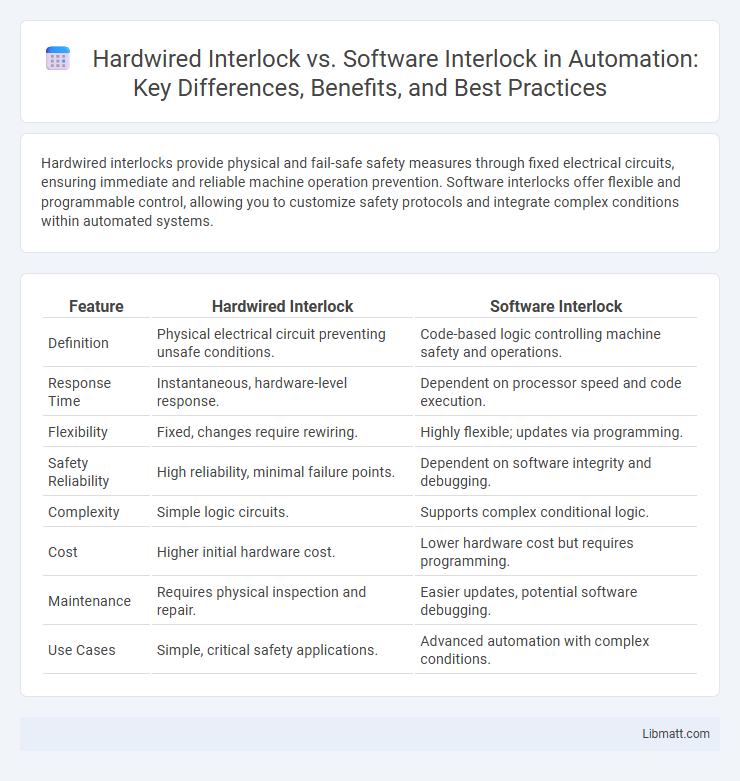

Hardwired interlocks provide physical and fail-safe safety measures through fixed electrical circuits, ensuring immediate and reliable machine operation prevention. Software interlocks offer flexible and programmable control, allowing you to customize safety protocols and integrate complex conditions within automated systems.

Table of Comparison

| Feature | Hardwired Interlock | Software Interlock |

|---|---|---|

| Definition | Physical electrical circuit preventing unsafe conditions. | Code-based logic controlling machine safety and operations. |

| Response Time | Instantaneous, hardware-level response. | Dependent on processor speed and code execution. |

| Flexibility | Fixed, changes require rewiring. | Highly flexible; updates via programming. |

| Safety Reliability | High reliability, minimal failure points. | Dependent on software integrity and debugging. |

| Complexity | Simple logic circuits. | Supports complex conditional logic. |

| Cost | Higher initial hardware cost. | Lower hardware cost but requires programming. |

| Maintenance | Requires physical inspection and repair. | Easier updates, potential software debugging. |

| Use Cases | Simple, critical safety applications. | Advanced automation with complex conditions. |

Introduction to Interlock Systems

Hardwired interlock systems use physical electrical circuits to enforce safety boundaries by preventing simultaneous or unsafe operations, providing reliable, fail-safe protection in industrial settings. Software interlock systems rely on programmable logic controllers (PLCs) or embedded software to monitor and control processes with greater flexibility and easier updates. Choosing between hardwired interlock and software interlock depends on your specific safety requirements, system complexity, and desired adaptability.

Defining Hardwired Interlocks

Hardwired interlocks are physical safety mechanisms designed using electrical circuits and mechanical components to prevent hazardous operations by enforcing fixed operational constraints. These interlocks rely on circuit breakers, relays, and switches, ensuring immediate response times and fail-safe conditions without software dependencies. Their inherent reliability and simplicity make them essential in critical safety applications where software failures could pose significant risks.

Understanding Software Interlocks

Software interlocks provide flexible, programmable control by using embedded algorithms to monitor system parameters and prevent unsafe operations. Unlike hardwired interlocks that rely on physical circuits, software interlocks enable real-time data analysis and adaptive safety measures within industrial automation and process control systems. These digital safety mechanisms reduce hardware complexity while improving diagnostic capabilities and system responsiveness.

Key Differences Between Hardwired and Software Interlocks

Hardwired interlocks rely on physical electrical circuits to ensure safety by preventing hazardous machine operations through direct hardware connections, offering high reliability and faster response times. Software interlocks depend on programmable logic controllers (PLCs) or microcontrollers that use software algorithms to monitor and control system states, providing flexibility and ease of modification but potentially introducing latency and cyber vulnerability. Your choice between hardwired and software interlocks should consider factors such as system complexity, required safety integrity levels, and maintenance capabilities.

Reliability and Safety Considerations

Hardwired interlocks offer higher reliability by using physical circuits that prevent failures caused by software bugs or cyber threats, ensuring consistent safety performance in critical systems. Software interlocks provide flexibility and ease of updates but may introduce risks related to programming errors or system crashes that can compromise safety. Your choice should weigh hardware's deterministic safety assurance against software's adaptability to maintain optimal operational security.

Installation and Maintenance Requirements

Hardwired interlock systems demand physical wiring and hardware installation, requiring skilled electricians for setup and routine inspections to ensure safety compliance. Software interlock solutions involve programming and network configurations, allowing easier updates and remote diagnostics but necessitating expertise in software management and cybersecurity. Your choice impacts ongoing maintenance complexity and the need for specialized technical skills to address system malfunctions or upgrades.

Flexibility and Scalability Comparison

Hardwired interlocks offer limited flexibility and scalability due to their fixed, physical wiring configurations, making modifications or expansions time-consuming and costly. Software interlocks provide enhanced flexibility and scalability by allowing easy updates, customization, and integration with other systems through programmable logic. Your control systems can benefit from software interlocks when requiring frequent changes or scalability to adapt to evolving operational needs.

Cost Implications: Hardwired vs Software Interlocks

Hardwired interlocks often entail higher upfront costs due to the need for physical components, wiring, and labor-intensive installation, but they provide reliable, fail-safe operation with minimal maintenance expenses over time. Software interlocks typically offer lower initial costs and easier modifications or updates, reducing downtime and enabling scalable solutions with less physical infrastructure investment. Your choice between hardwired and software interlocks should consider ongoing maintenance costs, flexibility requirements, and the criticality of system safety to optimize budget allocation.

Real-World Applications and Industry Use Cases

Hardwired Interlock systems provide reliable physical safety mechanisms in critical industries such as oil and gas, manufacturing, and power plants, ensuring immediate response to hazardous conditions without software delays. Software Interlock offers flexible control and easy updates in automated environments like robotics, automotive systems, and smart factories, enabling complex logic execution and integration with digital monitoring tools. Your choice between Hardwired and Software Interlock depends on industry requirements for response speed, complexity, and safety certification standards.

Choosing the Right Interlock System for Your Needs

Choosing the right interlock system depends on factors like safety requirements, system complexity, and operational flexibility. Hardwired interlocks provide reliable, fail-safe physical connections ideal for high-risk environments, while software interlocks offer customizable control and easier updates for dynamic processes. Your decision should balance the need for immediate hardware fail-safety against the adaptability and scalability offered by software solutions.

Hardwired Interlock vs Software Interlock Infographic

libmatt.com

libmatt.com