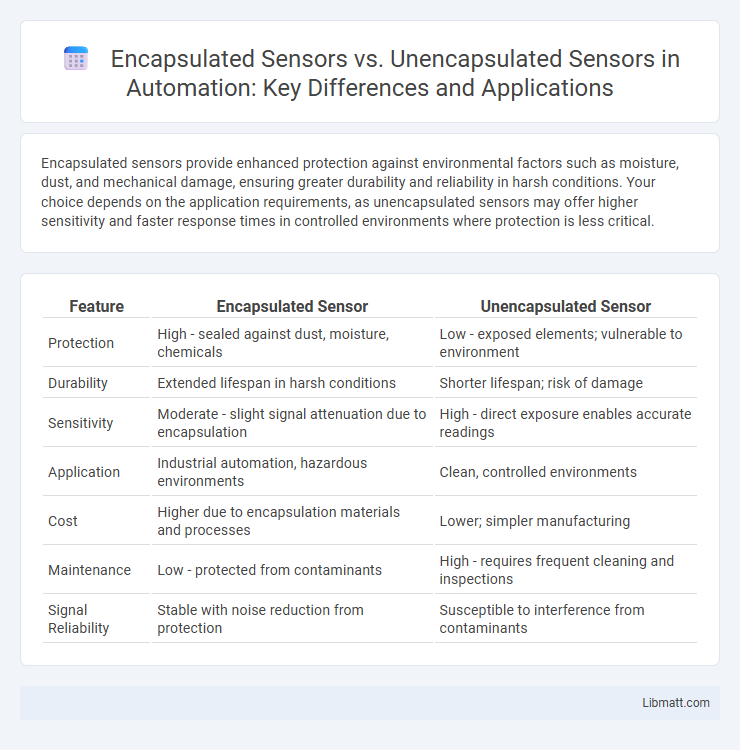

Encapsulated sensors provide enhanced protection against environmental factors such as moisture, dust, and mechanical damage, ensuring greater durability and reliability in harsh conditions. Your choice depends on the application requirements, as unencapsulated sensors may offer higher sensitivity and faster response times in controlled environments where protection is less critical.

Table of Comparison

| Feature | Encapsulated Sensor | Unencapsulated Sensor |

|---|---|---|

| Protection | High - sealed against dust, moisture, chemicals | Low - exposed elements; vulnerable to environment |

| Durability | Extended lifespan in harsh conditions | Shorter lifespan; risk of damage |

| Sensitivity | Moderate - slight signal attenuation due to encapsulation | High - direct exposure enables accurate readings |

| Application | Industrial automation, hazardous environments | Clean, controlled environments |

| Cost | Higher due to encapsulation materials and processes | Lower; simpler manufacturing |

| Maintenance | Low - protected from contaminants | High - requires frequent cleaning and inspections |

| Signal Reliability | Stable with noise reduction from protection | Susceptible to interference from contaminants |

Introduction to Sensor Encapsulation

Sensor encapsulation involves enclosing sensors within protective materials to enhance durability and performance in harsh environments. Encapsulated sensors offer improved resistance to moisture, dust, and mechanical stress compared to unencapsulated sensors, which are more vulnerable to damage and contamination. This protective barrier ensures longer sensor lifespan and consistent signal accuracy, making encapsulation crucial in industrial and outdoor applications.

Defining Encapsulated Sensors

Encapsulated sensors are devices enclosed within a protective casing that shields sensitive components from environmental factors such as moisture, dust, and mechanical damage, enhancing durability and reliability. This encapsulation improves sensor performance in harsh conditions by preventing contamination and corrosion that can affect unencapsulated sensors. In contrast, unencapsulated sensors lack this protective barrier, making them more vulnerable to external damage but often allowing for higher sensitivity and faster response times in controlled environments.

Understanding Unencapsulated Sensors

Unencapsulated sensors consist of exposed sensing elements without protective encapsulation, allowing for direct interaction with the surrounding environment, which enhances sensitivity and response time in applications such as gas detection and biosensing. These sensors are more vulnerable to environmental contaminants, moisture, and mechanical damage, requiring careful handling and specific operating conditions to maintain performance and longevity. Understanding the trade-offs between sensitivity and durability is essential when selecting unencapsulated sensors for precise, real-time measurement tasks.

Key Differences Between Encapsulated and Unencapsulated Sensors

Encapsulated sensors feature protective coatings that shield internal components from moisture, dust, and mechanical damage, enhancing durability and reliability in harsh environments. Unencapsulated sensors lack this protective layer, offering higher sensitivity and faster response times but are more vulnerable to environmental factors. Your choice depends on application needs where environmental protection or sensor performance sensitivity is prioritized.

Advantages of Encapsulated Sensors

Encapsulated sensors offer enhanced protection against environmental factors such as moisture, dust, and mechanical damage, extending their operational lifespan and reliability in harsh conditions. Their sealed design significantly reduces the risk of contamination and corrosion, ensuring consistent performance and accuracy over time. This makes encapsulated sensors ideal for industrial applications requiring durability and stable readings in challenging environments.

Benefits of Unencapsulated Sensors

Unencapsulated sensors offer enhanced sensitivity and faster response times due to the absence of protective coatings that can hinder signal detection. Their direct exposure to the environment allows for more accurate and immediate measurements, making them ideal for applications requiring real-time data. You can benefit from improved performance in scenarios where sensor agility and precision are critical, such as chemical detection or environmental monitoring.

Common Applications for Encapsulated Sensors

Encapsulated sensors are widely used in harsh environments such as automotive, industrial automation, and medical devices where protection against moisture, dust, and chemicals is critical. Their hermetic sealing enhances reliability and longevity in applications like pressure monitoring, humidity sensing, and wearable health technology. These sensors maintain accurate performance under extreme conditions, making them essential for safety-critical and long-term monitoring systems.

Ideal Use Cases for Unencapsulated Sensors

Unencapsulated sensors offer superior sensitivity and faster response times, making them ideal for applications requiring precise environmental monitoring or quick detection of chemical changes. These sensors excel in controlled laboratory conditions and in research where direct interaction with the sensor surface enhances measurement accuracy. Your choice of an unencapsulated sensor is perfect when detecting trace gases, biological analytes, or in scenarios demanding high-performance sensing with minimal protective barriers.

Decision Factors: Choosing the Right Sensor Type

Decision factors for choosing between encapsulated and unencapsulated sensors include environmental exposure, application requirements, and durability needs. Encapsulated sensors offer enhanced protection against moisture, dust, and chemicals, making them ideal for harsh or outdoor conditions, while unencapsulated sensors provide higher sensitivity and faster response times suitable for controlled environments. Consideration of factors such as operating temperature range, vibration resistance, and maintenance accessibility is crucial to determine the optimal sensor type for specific industrial or scientific applications.

Future Trends in Sensor Encapsulation Technology

Advancements in sensor encapsulation technology are focusing on developing ultra-thin, flexible materials that enhance durability while maintaining sensor sensitivity in harsh environments. Emerging trends include the integration of nanomaterials and smart coatings that provide self-healing properties and improved resistance to moisture, temperature fluctuations, and chemical exposure. These innovations aim to extend the lifespan and reliability of encapsulated sensors compared to unencapsulated versions, enabling broader applications in wearable devices, industrial monitoring, and IoT ecosystems.

Encapsulated Sensor vs Unencapsulated Sensor Infographic

libmatt.com

libmatt.com