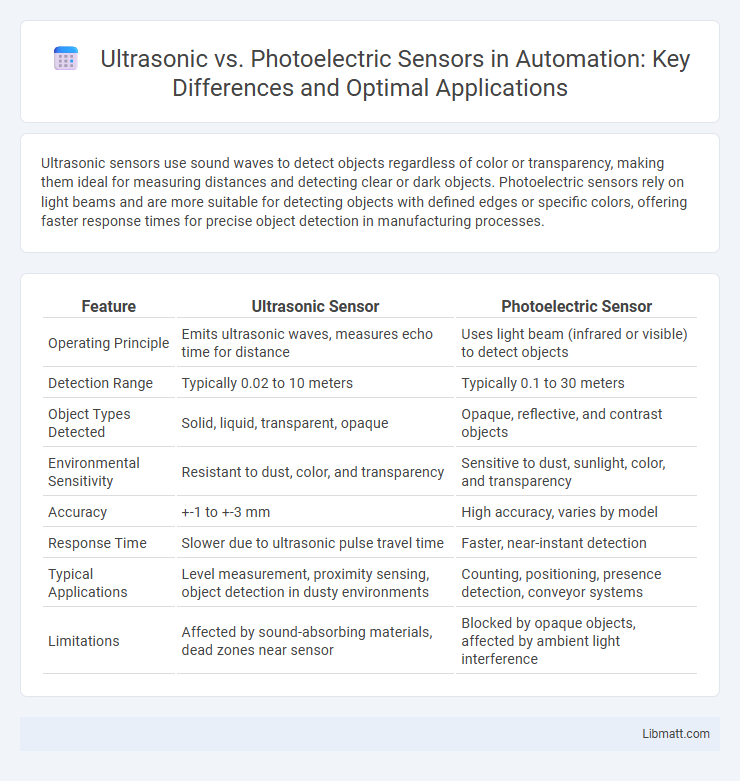

Ultrasonic sensors use sound waves to detect objects regardless of color or transparency, making them ideal for measuring distances and detecting clear or dark objects. Photoelectric sensors rely on light beams and are more suitable for detecting objects with defined edges or specific colors, offering faster response times for precise object detection in manufacturing processes.

Table of Comparison

| Feature | Ultrasonic Sensor | Photoelectric Sensor |

|---|---|---|

| Operating Principle | Emits ultrasonic waves, measures echo time for distance | Uses light beam (infrared or visible) to detect objects |

| Detection Range | Typically 0.02 to 10 meters | Typically 0.1 to 30 meters |

| Object Types Detected | Solid, liquid, transparent, opaque | Opaque, reflective, and contrast objects |

| Environmental Sensitivity | Resistant to dust, color, and transparency | Sensitive to dust, sunlight, color, and transparency |

| Accuracy | +-1 to +-3 mm | High accuracy, varies by model |

| Response Time | Slower due to ultrasonic pulse travel time | Faster, near-instant detection |

| Typical Applications | Level measurement, proximity sensing, object detection in dusty environments | Counting, positioning, presence detection, conveyor systems |

| Limitations | Affected by sound-absorbing materials, dead zones near sensor | Blocked by opaque objects, affected by ambient light interference |

Introduction to Ultrasonic and Photoelectric Sensors

Ultrasonic sensors utilize high-frequency sound waves to detect objects and measure distance by calculating the time it takes for the echoes to return, making them ideal for detecting transparent or reflective surfaces. Photoelectric sensors employ light beams, either through diffuse reflection, retro-reflective, or through-beam methods, to sense the presence or absence of objects with high precision and fast response times. Both sensor types are essential in automation and industrial applications, with ultrasonic sensors excelling in non-contact distance measurement and photoelectric sensors providing reliable object detection in varied lighting conditions.

Working Principles of Ultrasonic Sensors

Ultrasonic sensors operate by emitting high-frequency sound waves and measuring the time it takes for the echo to return after reflecting off an object, enabling precise distance detection. These sensors are ideal for detecting transparent, shiny, or irregularly shaped objects that photoelectric sensors may struggle with, as they do not rely on light beams. Understanding the working principles of ultrasonic sensors can help you select the right technology for reliable object detection and measurement in various industrial applications.

Working Principles of Photoelectric Sensors

Photoelectric sensors operate by emitting a light beam, typically infrared, from an emitter to a receiver or reflector, detecting objects based on the interruption or reflection of this beam. When an object enters the sensing range, it changes the intensity or path of the light, triggering the sensor to send an output signal. These sensors are widely used for accurate and fast detection in automation, packaging, and safety applications.

Key Differences Between Ultrasonic and Photoelectric Sensors

Ultrasonic sensors detect objects by emitting high-frequency sound waves and measuring the echo time, enabling precise distance measurement regardless of color or transparency. Photoelectric sensors use light beams to detect objects based on interruption or reflection, making them ideal for detecting small or transparent objects but sensitive to environmental conditions like dust or ambient light. Key differences include detection method, accuracy in various conditions, and suitability for specific applications such as object detection in harsh environments (ultrasonic) versus fast, precise detection in clean settings (photoelectric).

Accuracy and Detection Range Comparison

Ultrasonic sensors offer high accuracy in distance measurement with typical ranges from 2 cm to 4 meters, excelling in detecting transparent or irregular objects where photoelectric sensors may struggle. Photoelectric sensors provide faster response times and longer detection ranges, often exceeding 10 meters, but their accuracy can be affected by ambient light and object color or reflectivity. The choice depends on application needs: ultrasonic sensors for precise distance and irregular surfaces, photoelectric sensors for quick detection at extended distances.

Applications and Use Cases

Ultrasonic sensors excel in applications requiring precise distance measurement and object detection in harsh environments, such as level monitoring in tanks, robotic navigation, and automotive parking assistance. Photoelectric sensors are widely used in manufacturing automation, packaging, and conveyor systems for reliable object presence detection and counting due to their high-speed response and accuracy. Industries prioritize ultrasonic sensors for non-contact detection of transparent or reflective objects, while photoelectric sensors dominate scenarios needing fast, precise detection of opaque parts.

Environmental Factors Affecting Performance

Ultrasonic sensors experience performance variations due to factors like temperature, humidity, and air pressure, which influence sound wave propagation and accuracy. Photoelectric sensors are susceptible to environmental conditions including dust, smoke, and ambient light interference, which can obstruct the optical path and reduce detection reliability. Both sensor types require consideration of operating environments to ensure optimal functionality and signal integrity in industrial applications.

Installation and Maintenance Considerations

Ultrasonic sensors require careful alignment and mounting to ensure accurate distance measurement, often needing periodic cleaning to prevent dirt buildup that can distort ultrasonic waves. Photoelectric sensors generally have simpler installation with flexible mounting options and require less frequent maintenance, though their lenses must be kept clear of dust and debris to maintain reliable beam detection. Your choice should consider the environment and ease of access for routine upkeep to minimize downtime and maintain sensor performance.

Cost and ROI Analysis

Ultrasonic sensors generally have higher initial costs compared to photoelectric sensors due to their advanced technology and longer detection range capabilities. However, their durability and reduced maintenance expenses often lead to a better return on investment (ROI) in applications involving harsh environments or variable target surfaces. Photoelectric sensors offer lower upfront costs and quick installation, making them cost-effective for simpler detection tasks but may incur higher replacement or calibration costs over time.

Choosing the Right Sensor for Your Application

Ultrasonic sensors excel in detecting objects regardless of color or transparency by measuring sound wave reflections, making them ideal for applications requiring precise distance measurement in dusty, smoky, or dark environments. Photoelectric sensors offer fast response times and high accuracy for detecting objects with defined optical properties, making them suitable for manufacturing lines where surface color or material consistency is uniform. Selecting the right sensor depends on environmental conditions, target materials, and the required detection range and accuracy.

Ultrasonic Sensor vs Photoelectric Sensor Infographic

libmatt.com

libmatt.com