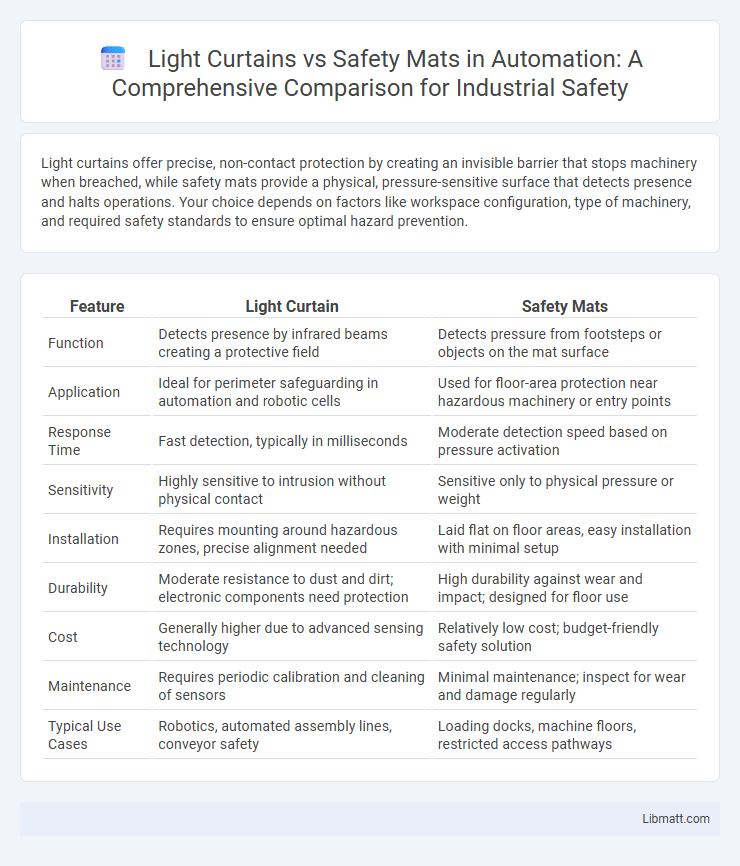

Light curtains offer precise, non-contact protection by creating an invisible barrier that stops machinery when breached, while safety mats provide a physical, pressure-sensitive surface that detects presence and halts operations. Your choice depends on factors like workspace configuration, type of machinery, and required safety standards to ensure optimal hazard prevention.

Table of Comparison

| Feature | Light Curtain | Safety Mats |

|---|---|---|

| Function | Detects presence by infrared beams creating a protective field | Detects pressure from footsteps or objects on the mat surface |

| Application | Ideal for perimeter safeguarding in automation and robotic cells | Used for floor-area protection near hazardous machinery or entry points |

| Response Time | Fast detection, typically in milliseconds | Moderate detection speed based on pressure activation |

| Sensitivity | Highly sensitive to intrusion without physical contact | Sensitive only to physical pressure or weight |

| Installation | Requires mounting around hazardous zones, precise alignment needed | Laid flat on floor areas, easy installation with minimal setup |

| Durability | Moderate resistance to dust and dirt; electronic components need protection | High durability against wear and impact; designed for floor use |

| Cost | Generally higher due to advanced sensing technology | Relatively low cost; budget-friendly safety solution |

| Maintenance | Requires periodic calibration and cleaning of sensors | Minimal maintenance; inspect for wear and damage regularly |

| Typical Use Cases | Robotics, automated assembly lines, conveyor safety | Loading docks, machine floors, restricted access pathways |

Introduction to Machine Safety Systems

Machine safety systems such as light curtains and safety mats play a crucial role in industrial environments to prevent accidents and ensure operator protection. Light curtains use infrared beams to create an invisible barrier that stops machinery when interrupted, offering precise detection for hazardous zones. Safety mats, equipped with pressure-sensitive sensors, detect the presence of personnel on the floor area and trigger machine shutdowns, providing reliable protection for areas with foot traffic.

Overview of Light Curtains

Light curtains are optoelectronic safety devices that create an invisible protective barrier by emitting infrared beams between a transmitter and receiver to detect object intrusion. They provide precise, non-contact sensing ideal for safeguarding hazardous machine zones, allowing continuous access while immediately stopping equipment upon beam interruption. Compared to safety mats, light curtains offer higher resolution detection, faster response times, and easier integration with automation systems.

Overview of Safety Mats

Safety mats are pressure-sensitive devices designed to detect the presence of a person or object on hazardous floor areas, instantly triggering machine shutdowns to prevent injuries. They offer durable, easy-to-install solutions compatible with various industrial settings, often used to safeguard access points or conveyor zones. Your safety system can be enhanced by integrating mats with complementary controls like light curtains for comprehensive area protection.

Key Differences Between Light Curtains and Safety Mats

Light curtains provide non-contact protection by creating an invisible infrared barrier, instantly stopping machinery when interrupted, while safety mats detect pressure applied directly to their surface to halt operations. Light curtains offer flexible, adjustable sensing heights and faster response times compared to safety mats, which are limited by size and placement. Your choice depends on the specific safety requirements and workspace layout, with light curtains suited for access control and safety mats ideal for floor area protection.

Typical Applications for Light Curtains

Light curtains are commonly used in manufacturing automation to provide non-contact safety protection around hazardous machinery such as presses, conveyors, and robotic cells. Their ability to detect the presence of an operator's hand or body part instantly enables safer operation without impeding workflow, ideal for assembly lines and packaging processes. Your facility can benefit from light curtains when precise, reliable presence sensing is critical to maintaining both productivity and safety compliance.

Typical Applications for Safety Mats

Safety mats are typically used in industrial environments to protect personnel from hazardous machine areas by detecting presence through pressure sensitivity. Common applications include guarding around presses, conveyors, robotic work cells, and assembly lines where workers need to safely stop machinery by stepping on or off the mat. Your facility benefits from enhanced protection in high-foot-traffic zones where consistent and reliable safety intervention is critical to preventing accidents.

Installation and Maintenance Considerations

Light curtains require precise alignment and mounting at appropriate heights to ensure the sensing field fully covers the hazardous area, often demanding professional calibration during installation. Safety mats involve embedding pressure-sensitive sensors into the floor, necessitating careful flush placement and durable covering to withstand foot traffic and equipment movement. Maintenance of light curtains centers on regular cleaning of sensors and verifying alignment, while safety mats require inspection for wear, damage, and electrical integrity to maintain reliable performance.

Safety Standards and Compliance

Light curtains and safety mats both comply with international safety standards such as ISO 13849 and IEC 61496, ensuring reliable machine safeguarding. Light curtains utilize photoelectric sensors to detect occlusions, providing high-resolution presence detection that meets Category 4 safety performance levels. Safety mats rely on pressure-sensitive surfaces and typically achieve Category 2 or 3 compliance, requiring regular functional testing to maintain certification.

Cost Comparison: Light Curtains vs Safety Mats

Light curtains generally have a higher upfront cost than safety mats due to advanced sensor technology and installation requirements. Safety mats offer a more affordable initial investment but may incur additional expenses over time because of wear and replacement needs. Your choice should balance the initial budget with long-term maintenance costs and safety effectiveness.

Choosing the Right Safety Solution for Your Needs

When selecting between light curtains and safety mats, consider the type of machinery and the required level of protection; light curtains offer non-contact, flexible detection ideal for automated manufacturing lines, while safety mats provide reliable pressure-sensitive protection for stationary equipment areas. Evaluate factors such as the environment, machine speed, and operator workflow to ensure optimal safety compliance and productivity. Proper assessment ensures that the chosen solution minimizes risk without compromising operational efficiency.

Light Curtain vs Safety Mats Infographic

libmatt.com

libmatt.com