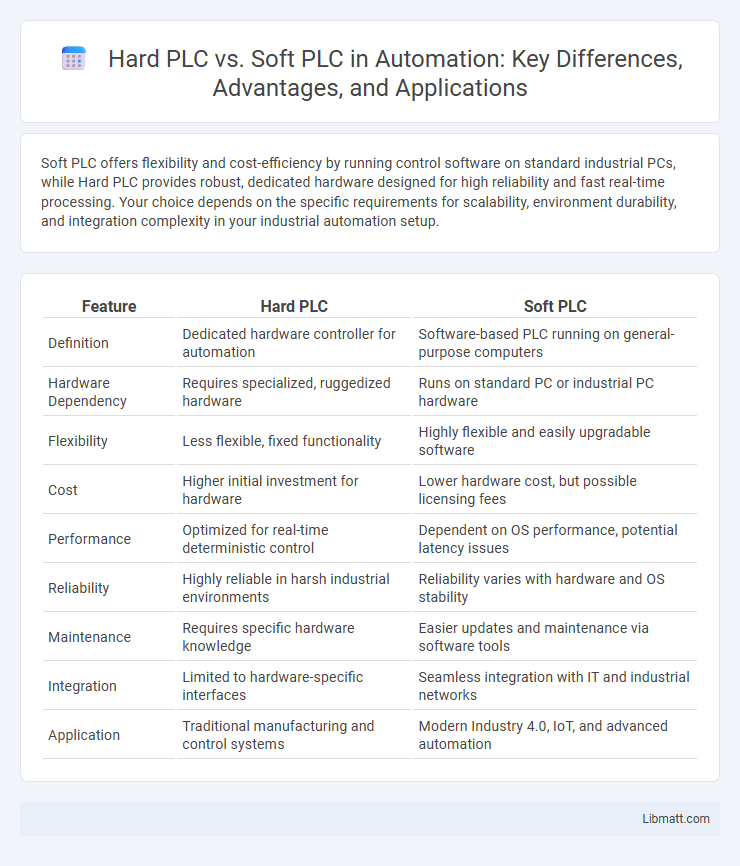

Soft PLC offers flexibility and cost-efficiency by running control software on standard industrial PCs, while Hard PLC provides robust, dedicated hardware designed for high reliability and fast real-time processing. Your choice depends on the specific requirements for scalability, environment durability, and integration complexity in your industrial automation setup.

Table of Comparison

| Feature | Hard PLC | Soft PLC |

|---|---|---|

| Definition | Dedicated hardware controller for automation | Software-based PLC running on general-purpose computers |

| Hardware Dependency | Requires specialized, ruggedized hardware | Runs on standard PC or industrial PC hardware |

| Flexibility | Less flexible, fixed functionality | Highly flexible and easily upgradable software |

| Cost | Higher initial investment for hardware | Lower hardware cost, but possible licensing fees |

| Performance | Optimized for real-time deterministic control | Dependent on OS performance, potential latency issues |

| Reliability | Highly reliable in harsh industrial environments | Reliability varies with hardware and OS stability |

| Maintenance | Requires specific hardware knowledge | Easier updates and maintenance via software tools |

| Integration | Limited to hardware-specific interfaces | Seamless integration with IT and industrial networks |

| Application | Traditional manufacturing and control systems | Modern Industry 4.0, IoT, and advanced automation |

Introduction to Hard PLC and Soft PLC

Hard PLCs are physical programmable logic controllers consisting of dedicated hardware units designed for industrial automation and real-time control. Soft PLCs operate as software applications on standard computing platforms, offering flexibility and integration within IT environments. Both types provide automation solutions, with Hard PLCs excelling in reliability and Soft PLCs enabling scalability and cost-effectiveness.

Understanding the Core Differences

Hard PLCs rely on dedicated hardware for control processes, offering high reliability and robustness in industrial automation environments. Soft PLCs run on standard computer systems with software emulating PLC functions, providing flexibility and easier integration with IT infrastructure. Understanding these core differences helps you choose the right control solution based on factors like system complexity, scalability, and maintenance requirements.

Hardware and Software Architecture Comparison

Hard PLC features dedicated hardware components including processors, memory, and input/output modules designed for real-time control applications, ensuring high reliability and low latency. Soft PLC operates on standard industrial PCs or embedded systems, relying on general-purpose hardware coupled with software-based control logic, offering flexibility but potentially higher latency and less deterministic performance. Hardware architecture in Hard PLC is tightly integrated for robustness, while Soft PLC leverages modular software layers on commodity hardware, allowing easier updates and customization.

Performance and Real-Time Capabilities

Hard PLCs offer superior performance and real-time capabilities due to their dedicated hardware designed specifically for industrial control tasks, ensuring minimal latency and high reliability in critical applications. Soft PLCs run on general-purpose computers, which can introduce variable response times and potential delays, making them less suited for stringent real-time requirements. Your choice depends on whether your system prioritizes deterministic execution and consistent cycle times over flexibility and integration with other software platforms.

Flexibility and Scalability Analysis

Hard PLCs provide robust, dedicated hardware solutions with limited flexibility and scalability, making them ideal for fixed, repetitive industrial processes but challenging to adapt or expand without significant hardware changes. Soft PLCs leverage software-based control on standard computing platforms, offering superior flexibility to modify control logic and easier scalability through upgrades or cloud integration, suitable for dynamic and evolving automation needs. Scalability in soft PLCs enables seamless integration with IoT devices and advanced analytics, while hard PLCs often require physical hardware additions to scale capacity or features.

Cost Implications and Budget Considerations

Hard PLC systems generally require higher upfront costs due to dedicated hardware components, specialized installation, and longer setup times. Soft PLCs, running on standard industrial PCs or servers, offer cost savings by leveraging existing hardware and easier scalability, reducing maintenance expenses over time. When considering your budget, evaluate not only initial investment but also long-term operational costs and potential for flexible upgrades with Soft PLC solutions.

Reliability and System Robustness

Hard PLCs offer superior reliability and system robustness due to their dedicated hardware components designed for industrial environments, ensuring minimal downtime and consistent performance. Soft PLCs, running on general-purpose hardware, may be more susceptible to system crashes and network issues, potentially impacting your control processes. For mission-critical applications, Hard PLCs provide a more stable and dependable solution compared to Soft PLC implementations.

Integration with Industrial Automation Systems

Hard PLCs offer robust hardware integration with industrial automation systems, providing reliable performance and real-time control in demanding environments. Soft PLCs, leveraging software platforms, enable flexible integration with existing IT infrastructure and cloud-based solutions, enhancing scalability and remote access. Your choice depends on whether you prioritize dedicated hardware resilience or adaptability with digital ecosystems.

Application Suitability: When to Choose Hard or Soft PLC

Hard PLCs are ideal for applications requiring high reliability, real-time processing, and harsh industrial environments such as manufacturing automation and critical process control. Soft PLCs suit flexible, cost-effective setups in less demanding environments where adaptability and easy integration with IT systems are priorities, such as simulation or small-scale automation. Your choice between Hard and Soft PLC depends on the application's need for ruggedness, processing speed, and system integration complexity.

Future Trends in PLC Technology

Future trends in PLC technology emphasize the shift from traditional hard PLCs to more flexible soft PLCs that run on standard IT hardware and support advanced industrial automation protocols. Soft PLCs enable seamless integration with IoT devices, cloud computing, and edge computing platforms, enhancing real-time data analytics and predictive maintenance for smarter manufacturing. Your industrial control systems will benefit from increased scalability, reduced costs, and easier software updates as soft PLC adoption accelerates in Industry 4.0 environments.

Hard PLC vs Soft PLC Infographic

libmatt.com

libmatt.com