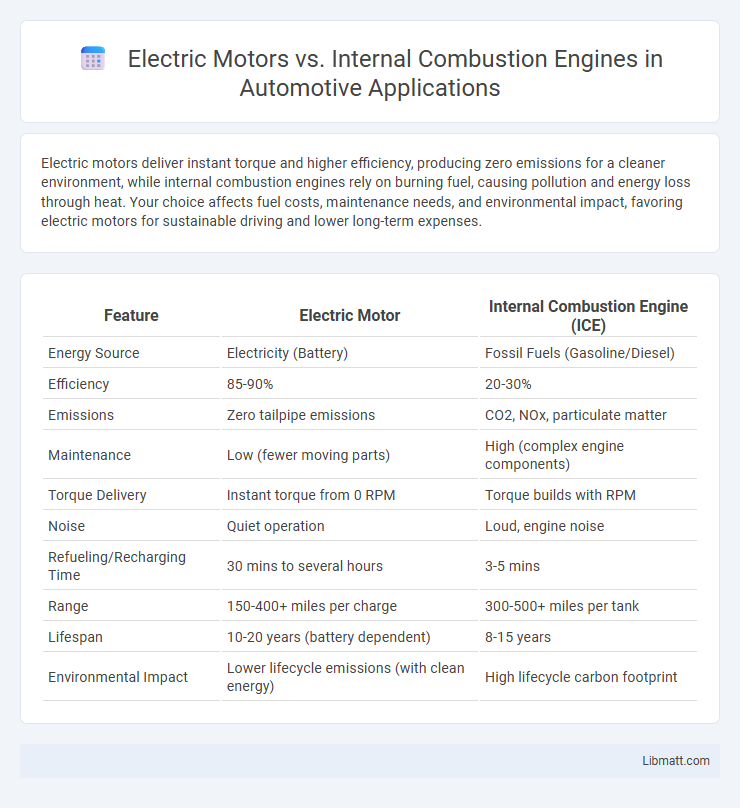

Electric motors deliver instant torque and higher efficiency, producing zero emissions for a cleaner environment, while internal combustion engines rely on burning fuel, causing pollution and energy loss through heat. Your choice affects fuel costs, maintenance needs, and environmental impact, favoring electric motors for sustainable driving and lower long-term expenses.

Table of Comparison

| Feature | Electric Motor | Internal Combustion Engine (ICE) |

|---|---|---|

| Energy Source | Electricity (Battery) | Fossil Fuels (Gasoline/Diesel) |

| Efficiency | 85-90% | 20-30% |

| Emissions | Zero tailpipe emissions | CO2, NOx, particulate matter |

| Maintenance | Low (fewer moving parts) | High (complex engine components) |

| Torque Delivery | Instant torque from 0 RPM | Torque builds with RPM |

| Noise | Quiet operation | Loud, engine noise |

| Refueling/Recharging Time | 30 mins to several hours | 3-5 mins |

| Range | 150-400+ miles per charge | 300-500+ miles per tank |

| Lifespan | 10-20 years (battery dependent) | 8-15 years |

| Environmental Impact | Lower lifecycle emissions (with clean energy) | High lifecycle carbon footprint |

Introduction: Electric Motor vs Internal Combustion Engine

Electric motors convert electrical energy into mechanical motion through electromagnetic induction, offering high efficiency and instant torque. Internal combustion engines burn fuel inside cylinders to produce power, with complex moving parts and emissions as byproducts. Your choice between these power sources affects performance, environmental impact, and maintenance requirements.

Fundamentals of Electric Motors

Electric motors operate based on electromagnetic principles, where electric current flowing through coils generates a magnetic field that interacts with permanent magnets or electromagnets to produce rotational motion. Unlike internal combustion engines that rely on fuel combustion to create mechanical energy, electric motors convert electrical energy directly into mechanical energy with high efficiency and minimal energy loss. Key components include the stator, rotor, and commutator or electronic controller, enabling precise speed and torque control for various applications.

Basics of Internal Combustion Engines

Internal combustion engines operate by igniting a fuel-air mixture within a combustion chamber, creating controlled explosions that drive pistons to produce mechanical power. These engines commonly use gasoline or diesel fuel and rely on a complex system of valves, spark plugs, and fuel injectors to manage ignition and intake processes. Their efficiency and power output depend on factors such as engine displacement, compression ratio, and fuel type.

Energy Efficiency Comparison

Electric motors convert over 85% of electrical energy into mechanical power, significantly outperforming internal combustion engines (ICE) which typically achieve only 20-30% thermal efficiency. The higher energy efficiency of electric motors reduces energy waste and lowers operating costs, contributing to decreased greenhouse gas emissions. This efficiency gap makes electric motors a superior choice for sustainable transportation and energy conservation efforts.

Environmental Impact and Emissions

Electric motors produce zero tailpipe emissions, significantly reducing air pollution and greenhouse gas emissions compared to internal combustion engines, which release carbon dioxide, nitrogen oxides, and particulate matter during fuel combustion. The environmental impact of electric motors is further minimized when powered by renewable energy sources, whereas internal combustion engines rely on fossil fuels that contribute to climate change and resource depletion. Your choice of vehicle with an electric motor supports cleaner air quality and a lower carbon footprint, directly benefiting environmental sustainability.

Maintenance and Reliability

Electric motors require significantly less maintenance than internal combustion engines due to fewer moving parts and no need for oil changes, spark plugs, or fuel filters. Your electric vehicle ensures higher reliability with reduced mechanical wear and lower chances of engine failure. Internal combustion engines face more frequent maintenance intervals and higher risks of component breakdowns, impacting long-term dependability.

Cost Factors: Purchase and Operation

Electric motors generally have higher upfront purchase costs due to advanced battery technology but offer significantly lower operational expenses thanks to reduced maintenance and energy costs compared to internal combustion engines (ICEs). Internal combustion engines incur continuous fuel expenses and more frequent servicing, driving up total ownership costs over time. Evaluating your budget for initial investment versus long-term savings is crucial when choosing between electric motors and ICEs.

Performance and Driving Experience

Electric motors deliver instant torque, providing rapid acceleration and smooth power delivery that enhances your driving experience with quiet operation and minimal vibration. Internal combustion engines (ICE) rely on fuel combustion cycles, resulting in delayed torque and less consistent power output, often accompanied by engine noise and vibrations. The seamless response and consistent performance of electric motors make them favorable for dynamic driving, while ICE vehicles can offer a more traditional auditory and tactile sensation favored by some enthusiasts.

Future Trends and Technological Advancements

Electric motors are rapidly evolving with advancements in battery technology, energy density, and charging infrastructure, boosting efficiency and driving range for future electric vehicles. Internal combustion engines face increasing regulatory pressure to reduce emissions, prompting innovations like hybridization and alternative fuels to improve sustainability. Your choice will increasingly favor electric drivetrains as technology progresses toward cleaner, more efficient transportation solutions.

Conclusion: Choosing the Right Powertrain

Selecting the right powertrain depends on factors such as efficiency, environmental impact, and application needs. Electric motors offer superior energy efficiency and zero tailpipe emissions, making them ideal for sustainable urban transportation and reducing carbon footprints. Internal combustion engines provide longer range and quicker refueling, often preferred for heavy-duty vehicles and long-distance travel where infrastructure for electric charging is limited.

Electric Motor vs Internal Combustion Engine Infographic

libmatt.com

libmatt.com