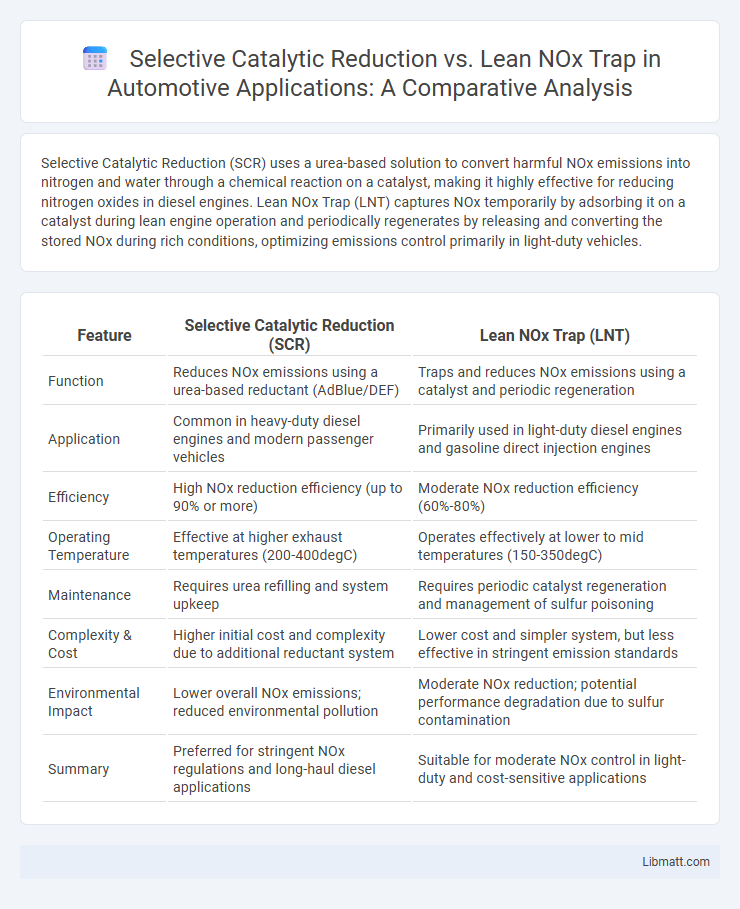

Selective Catalytic Reduction (SCR) uses a urea-based solution to convert harmful NOx emissions into nitrogen and water through a chemical reaction on a catalyst, making it highly effective for reducing nitrogen oxides in diesel engines. Lean NOx Trap (LNT) captures NOx temporarily by adsorbing it on a catalyst during lean engine operation and periodically regenerates by releasing and converting the stored NOx during rich conditions, optimizing emissions control primarily in light-duty vehicles.

Table of Comparison

| Feature | Selective Catalytic Reduction (SCR) | Lean NOx Trap (LNT) |

|---|---|---|

| Function | Reduces NOx emissions using a urea-based reductant (AdBlue/DEF) | Traps and reduces NOx emissions using a catalyst and periodic regeneration |

| Application | Common in heavy-duty diesel engines and modern passenger vehicles | Primarily used in light-duty diesel engines and gasoline direct injection engines |

| Efficiency | High NOx reduction efficiency (up to 90% or more) | Moderate NOx reduction efficiency (60%-80%) |

| Operating Temperature | Effective at higher exhaust temperatures (200-400degC) | Operates effectively at lower to mid temperatures (150-350degC) |

| Maintenance | Requires urea refilling and system upkeep | Requires periodic catalyst regeneration and management of sulfur poisoning |

| Complexity & Cost | Higher initial cost and complexity due to additional reductant system | Lower cost and simpler system, but less effective in stringent emission standards |

| Environmental Impact | Lower overall NOx emissions; reduced environmental pollution | Moderate NOx reduction; potential performance degradation due to sulfur contamination |

| Summary | Preferred for stringent NOx regulations and long-haul diesel applications | Suitable for moderate NOx control in light-duty and cost-sensitive applications |

Introduction to NOx Emission Control Technologies

Selective Catalytic Reduction (SCR) and Lean NOx Trap (LNT) are advanced NOx emission control technologies designed to reduce nitrogen oxide pollutants from diesel and lean-burn gasoline engines. SCR uses a reductant, commonly urea, injected into the exhaust stream to convert NOx into nitrogen and water over a catalyst, achieving high reduction efficiency at a wide range of operating conditions. LNT captures and stores NOx during lean engine operation and releases it for reduction during brief rich conditions, offering a compact solution but typically with lower overall NOx conversion efficiency compared to SCR.

Overview of Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) is an advanced emissions control technology that reduces nitrogen oxides (NOx) from diesel and gasoline engines by injecting a urea-based reductant into the exhaust stream. The injected ammonia reacts with NOx over a catalyst, converting harmful gases into nitrogen and water, thereby significantly lowering tailpipe emissions. SCR systems are widely adopted in heavy-duty vehicles due to their high NOx reduction efficiency and compatibility with stringent emission standards like Euro 6 and EPA Tier 4.

Overview of Lean NOx Trap (LNT)

Lean NOx Trap (LNT) technology effectively reduces nitrogen oxide (NOx) emissions from lean-burn engines by adsorbing NOx during lean operation and subsequently releasing and converting it during short rich cycles. LNT systems use a ceramic substrate coated with precious metals and alkaline earth metals to trap NOx, making them suitable for diesel and lean gasoline engines. Compared to Selective Catalytic Reduction (SCR), LNT offers a compact design without requiring a separate reductant like urea, but may have lower NOx conversion efficiency under highly lean conditions.

Working Principle: SCR vs LNT

Selective Catalytic Reduction (SCR) reduces nitrogen oxides (NOx) by injecting a urea-based solution into the exhaust stream, where it reacts on a catalyst to convert NOx into nitrogen and water. Lean NOx Trap (LNT) adsorbs NOx during lean engine operation and releases it during periodic rich conditions, where it is catalytically reduced into harmless gases. Both technologies target NOx emissions but differ in their reaction mechanisms and operational strategies for emission control.

Efficiency in NOx Reduction

Selective Catalytic Reduction (SCR) achieves high efficiency in NOx reduction by injecting a urea-based reductant into the exhaust stream, converting NOx into harmless nitrogen and water with reduction efficiencies often exceeding 90%. Lean NOx Trap (LNT) systems adsorb NOx during lean engine operation and periodically regenerate by temporarily operating rich, achieving moderate NOx reduction efficiency typically around 60-80%. Your choice depends on factors such as vehicle application and emission standards, with SCR generally preferred for superior NOx control in heavy-duty diesel engines.

Operational Conditions and Requirements

Selective Catalytic Reduction (SCR) operates efficiently under high temperatures ranging from 250degC to 450degC, requiring a steady supply of ammonia or urea as a reducing agent to convert NOx into nitrogen and water. Lean NOx Trap (LNT) systems function effectively at lower temperatures, typically between 200degC and 350degC, by adsorbing NOx during lean engine operation and periodically regenerating under rich conditions to reduce stored NOx. Your choice between SCR and LNT depends on specific operational conditions, including exhaust temperature profiles and the availability of reductants to meet emission standards.

Catalyst Materials and Lifespan

Selective Catalytic Reduction (SCR) utilizes a catalyst typically composed of titanium dioxide, vanadium pentoxide, and tungsten trioxide, known for its durability and ability to operate efficiently over 100,000 miles. Lean NOx Trap (LNT) catalysts primarily incorporate platinum, cerium, and barium oxides, which offer effective NOx storage but tend to degrade faster due to sulfur poisoning and thermal aging, limiting their lifespan to around 50,000 miles. SCR catalysts generally boast longer operational life and greater sulfur tolerance compared to LNT systems, making them more suitable for heavy-duty and long-haul applications.

Advantages and Limitations: SCR vs LNT

Selective Catalytic Reduction (SCR) offers high NOx reduction efficiency, typically exceeding 90%, making it ideal for heavy-duty diesel engines and large-scale applications, with the advantage of using a urea-based reductant. Lean NOx Trap (LNT) systems provide a simpler, compact solution without requiring a separate reductant tank, suitable for light-duty vehicles, but generally achieve lower NOx conversion rates and may face durability challenges due to sulfur poisoning. Your choice between SCR and LNT depends on factors like vehicle type, space constraints, regulatory requirements, and maintenance capabilities.

Typical Applications in Automotive and Industrial Sectors

Selective Catalytic Reduction (SCR) is widely used in heavy-duty diesel engines, such as trucks, buses, and industrial machinery, due to its high efficiency in reducing nitrogen oxides (NOx) emissions in lean burn conditions. Lean NOx Trap (LNT) technology is commonly applied in light-duty gasoline and diesel vehicles where space constraints and lower exhaust temperatures limit SCR implementation. Your choice between SCR and LNT depends on the specific application requirements, emission standards, and operational conditions in both automotive and industrial sectors.

Future Trends in NOx Control Technologies

Selective Catalytic Reduction (SCR) and Lean NOx Trap (LNT) represent two leading NOx control technologies, with SCR showing greater potential for scalability and efficiency in heavy-duty applications. The future trends emphasize integration of SCR with advanced sensors and AI-driven control systems to optimize urea dosing and minimize ammonia slip. Your NOx reduction strategy can benefit from these innovations, as emerging technologies aim to meet stricter emission standards while improving fuel economy.

Selective Catalytic Reduction vs Lean NOx Trap Infographic

libmatt.com

libmatt.com